Chez EDIBON, nous sommes engagés à renforcer les compétences comme pilier stratégique pour la compétitivité et le bien-être social de l'Union européenne. Une formation adéquate renforce non seulement l'économie, mais permet également aux individus de participer pleinement à la société et à la...

0

Sélection

/

Vide

Votre sélection

Il n'y a plus d'articles dans votre sélection

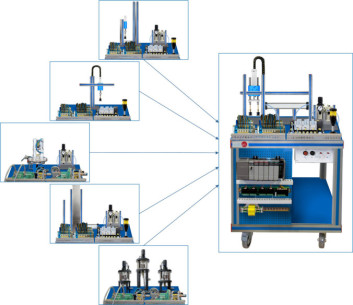

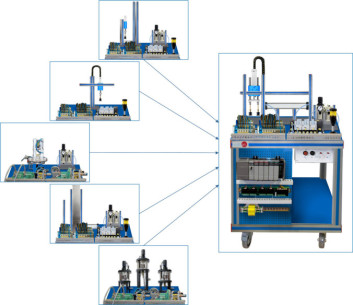

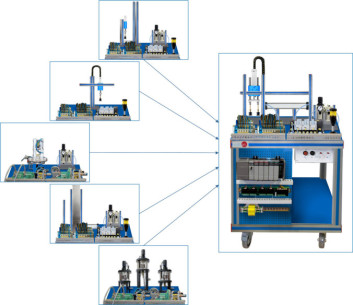

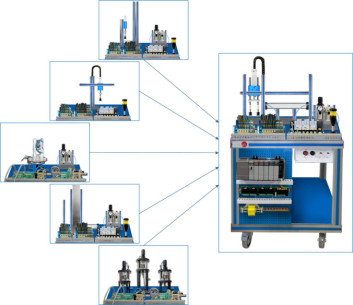

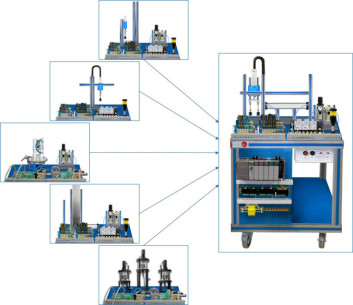

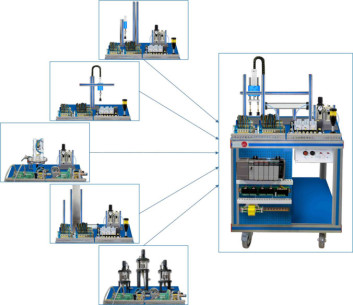

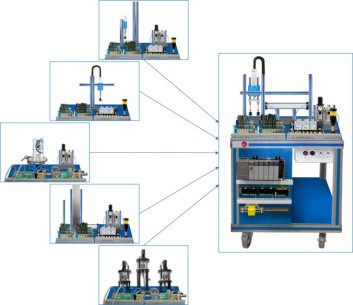

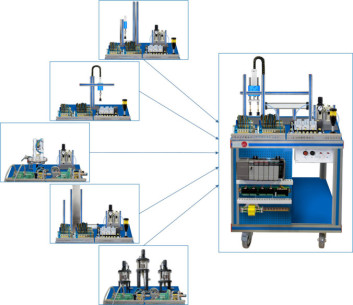

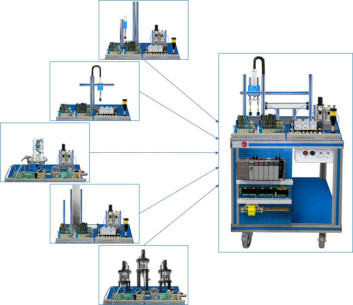

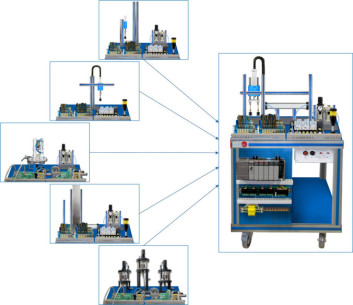

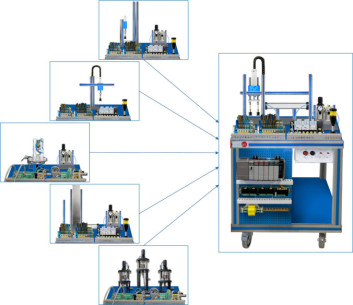

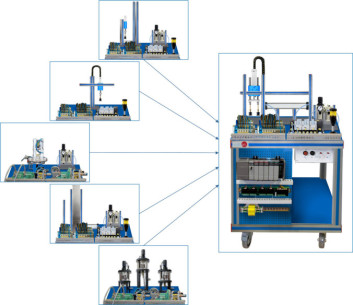

AE-PLC-MEMB Usine-école d'Emballage

SYSTEMES INNOVANTS

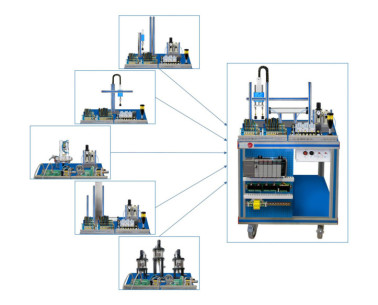

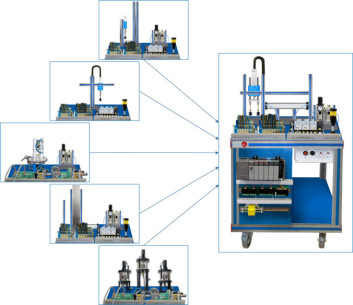

La Usine-école d’Emballage, "AE-PLC-MEMB", a été conçue par EDIBON pour l’étude pratique d’un processus automatisé d’embouteillage en cinq étapes : approvisionnement, remplissage, alimentation des bouchons, fermeture et extraction des récipients. Elle intègre une conception utilisant la technologie pneumatique, des capteurs industriels et un contrôle par automate programmable, tout en étant compatible avec les systèmes de fabrication flexible.

NOUVELLES LIÉES

Description Générale

La Usine-école d’Emballage, "AE-PLC-MEMB", conçue par EDIBON, est une table rotative automatique dotée d’un système d’alimentation des récipients, d’un système de remplissage contrôlé à l’eau, d’un distributeur de bouchons, d’un système de fermeture des récipients et, enfin, d’un système d’extraction vers un support de récipients complets.

La usine-école "AE-PLC-MEMB" est conçue comme un système modulaire afin d’en faciliter la compréhension.

Les principaux composants sont :

- L’automate programmable (PLC) : il est composé de l’unité CPU et de tous les modules supplémentaires nécessaires pour assurer le fonctionnement correct de la usine-école de travail.

- Le panneau de contrôle : avec boutons de mise en marche/arrêt, bouton d’arrêt d’urgence, bouton de réinitialisation, voyants lumineux indiquant l’état actuel du processus, etc.

- Le circuit pneumatique : il contient les électrovannes nécessaires, les composants de pression, les filtres et régulateurs garantissant le fonctionnement adéquat de l’unité, ainsi que différents types d’actionneurs pneumatiques.

- La usine-école de travail : elle est composée de composants industriels réels utilisés dans les systèmes de table rotative, tels que détecteurs à lames, capteurs de présence, moteur à courant continu, capteurs inductifs, capteurs capacitifs, table rotative à quatre positions, etc.

Le circuit pneumatique et la usine-école de travail sont répartis dans les sections suivantes :

- Système de traitement de l’air. Il contient un ensemble filtre-régulateur avec piège à eau et vanne de coupure pour contrôler l’entrée de la pression d’air dans l’unité. Il inclut un manomètre à double échelle permettant de visualiser le niveau de pression fourni à l’unité.

- Section d’alimentation des récipients. Elle comporte un stockage vertical permettant d’introduire les récipients sans bouchon. Deux vérins double effet assurent la chute des récipients un par un. Chacun de ces vérins possède son propre régulateur de débit d’air afin d’en ajuster la vitesse.

- Section de déplacement des récipients. Il s’agit d’une table rotative équipée de quatre supports pour les récipients. Grâce à sa rotation, effectuée par un moteur à courant continu, le récipient est acheminé vers chaque étape correspondante du processus.

- Section de remplissage. Elle comprend deux réservoirs situés dans la partie inférieure de la table de l’unité. L’un est un réservoir de réserve et l’autre fournit l’eau à la usine-école grâce à un système d’électrovannes, une pompe submersible alimentée en courant continu et un siphon permettant le remplissage correct du récipient. Elle inclut également un capteur capacitif de détection de récipient pour éviter l’activation du remplissage lorsque le récipient n’est pas en position ou est absent.

- Section d’alimentation des bouchons et de fermeture des récipients. Elle comporte un vérin double effet qui pousse les bouchons un par un selon les besoins du processus. Ces bouchons restent en attente dans un stockage vertical placé en dehors de la table rotative. Au moyen d’actionneurs de déplacement vertical et horizontal, et d’un éjecteur à vide avec ventouse, la usine-école saisit le bouchon, le transporte et l’appuie ensuite sur le récipient, assurant ainsi sa fermeture.

- Section d’extraction du récipient. Elle comprend un ensemble d’actionneurs, parmi lesquels des pinces pneumatiques qui saisissent le récipient et le transportent vers le support de stockage, où ils s’accumulent.

- Tour de signalisation. Elle contient des voyants LED vert, jaune et rouge pour indiquer l’état du système.

- Bloc d’électrovannes. Il s’agit d’un bloc de distribution pneumatique comprenant neuf électrovannes : huit électrovannes monostables cinq voies et une électrovanne monostable trois voies.

- Bloc de borniers électriques. Il contient tous les signaux de l’unité, accessibles et identifiés, permettant la vérification manuelle du système. Le bloc est doté de borniers codés par couleur pour aider l’utilisateur à identifier chaque type de signal, ainsi que le nom correspondant.

Des exercices et pratiques guidées

EXERCICES GUIDÉS INCLUS DANS LE MANUEL

- Introduction au Système de Fabrication Flexible (FMS).

- Introduction à la pneumatique et à l’électropneumatique.

- Configuration d’une application pneumatique.

- Introduction au contrôle pneumatique.

- Étude des capteurs de détection.

- Commande manuelle d’une table tournante.

- Commande automatique d’une table tournante.

- Exemple d’application industrielle.

UNITÉS SIMILAIRES DISPONIBLES

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-FT

The "AE-PLC-FT" is a filtration system commanded by a PLC. The "AE-PLC-FT" is composed of two tanks with a filter between them. The liquids are pumped from the first tank into the second tank through the filter using a pump and different types of...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-MS

Usine-école de Mélange

The "AE-PLC-MS" is a mixing system commanded by a PLC. The "AE-PLC-MS" is composed of three tanks with different liquids. These liquids are pumped and mixed in a reactor vessel using a pump and different valves. The system is equipped with flow...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-PHD

Usine-école de Poinçonnage

The "AE-PLC-PHD" is a processing workstation commanded by a PLC. This unit takes a piece and introduces it inside the punching zone that is protected with a polycarbonate screen. Once the piece is inside the punching zone, the hydraulic punching...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-FS

Usine-école de Remplissage

The "AE-PLC-FS" is a filling system commanded by a PLC. The workstation detects the bottles that arrive on a conveyor belt to the filling position and pumps liquids from a reservoir tank into the bottles using a pump and different types of valves....

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-CRS

Usine-école de Bouchage

The "AE-PLC-CRS" is a corking system commanded by a PLC. The workstation detects the bottles that arrives on a conveyor belt to the corking position and closes them with a cap using a pressing cylinder. The "AE-PLC-CRS" also includes different...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-APB

Usine-école d'Ouverture de Boîtes

The "AE-PLC-APB" is a bottles opening system commanded by a PLC. The unit is equipped with different containers and a retention system based on a cylinder, in order to allow the Robotic Arm Workstation "AE-BR" or the SCARA Arm Workstation "AE-SCA"...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-M

Usine-école de Montage

The "AE-PLC-M" is a mounting workstation commanded by a PLC that provides pieces to the system and mount them inside of the base pieces.The "AE-PLC-M" keeps the pieces in a vertical storage. The workstation take the pieces one by one, the quality...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-P

Usine-école de Pressage Automatique

The "AE-PLC-P" is an automatic pressing workstation commanded by a PLC. The "AE-PLC-P" moves the pieces from the input zone tothe pressing zone, once the piece is detected in the pressing zone, the "AE-PLC-P" emulates pressing the pieces with a...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-AT

Usine-école de Vissage Automatique

The "AE-PLC-AT" is an automatic screw workstation commanded by a PLC that supply and mount four screws in a piece. The "AE-PLC-AT" keeps the screws in a vertical storage. The workstation take the screws, one by one, and a pneumatic manipulator...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-MET

Usine-école d'Étiquetage

The "AE-PLC-MET" is an automatic labelling machine commanded by a PLC. The "AE-PLC-MET" also include a transporting system that carries the incoming bottles to the labelling zone, supplying the bottles one by one.The "AE-PLC-MET" workstation is...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-ST

Usine-école de Perçage

The "AE-PLC-ST" is an automatic drilling workstation commanded by a PLC. The "AE-PLC-ST" also include a conveyor system to transport the incoming pieces to the drilling zone where the drilling machine simulate the process.The "AE-PLC-ST"...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-SMOLD

Usine-école de Moulage

The "AE-PLC-SMOLD" is an automatic molding workstation commanded by a PLC. The "AE-PLC-SMOLD" also include a conveyor system to transport the incoming pieces to the molding zone where the unit simulate a molding process by punching the piece with...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-SCOR

Usine-école de Découpe

La Usine-école de Découpe, "AE-PLC-SCOR", conçue par EDIBON, est un poste de découpe automatique commandé par un automate. Le "AE-PLC-SCOR" comprend également un système de convoyeur pour transporter les pièces entrantes vers la zone de découpe où...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-CP

Usine-école de Contrôle de Processus

The "AE-PLC-CP" is a process control workstation commanded by a PLC that coordinates the work of 3 industrial controllers that regulates in parallel the level, flow rate, temperature and pressure processes. The "AE-PLC-CP" workstation has been...

EQUIPEMENT COMPLEMENTAIRE

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-M

Usine-école de Montage

The "AE-PLC-M" is a mounting workstation commanded by a PLC that provides pieces to the system and mount them inside of the base pieces.The "AE-PLC-M" keeps the pieces in a vertical storage. The workstation take the pieces one by one, the quality...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-P

Usine-école de Pressage Automatique

The "AE-PLC-P" is an automatic pressing workstation commanded by a PLC. The "AE-PLC-P" moves the pieces from the input zone tothe pressing zone, once the piece is detected in the pressing zone, the "AE-PLC-P" emulates pressing the pieces with a...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-AT

Usine-école de Vissage Automatique

The "AE-PLC-AT" is an automatic screw workstation commanded by a PLC that supply and mount four screws in a piece. The "AE-PLC-AT" keeps the screws in a vertical storage. The workstation take the screws, one by one, and a pneumatic manipulator...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-MET

Usine-école d'Étiquetage

The "AE-PLC-MET" is an automatic labelling machine commanded by a PLC. The "AE-PLC-MET" also include a transporting system that carries the incoming bottles to the labelling zone, supplying the bottles one by one.The "AE-PLC-MET" workstation is...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-ST

Usine-école de Perçage

The "AE-PLC-ST" is an automatic drilling workstation commanded by a PLC. The "AE-PLC-ST" also include a conveyor system to transport the incoming pieces to the drilling zone where the drilling machine simulate the process.The "AE-PLC-ST"...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-SMOLD

Usine-école de Moulage

The "AE-PLC-SMOLD" is an automatic molding workstation commanded by a PLC. The "AE-PLC-SMOLD" also include a conveyor system to transport the incoming pieces to the molding zone where the unit simulate a molding process by punching the piece with...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-SCOR

Usine-école de Découpe

La Usine-école de Découpe, "AE-PLC-SCOR", conçue par EDIBON, est un poste de découpe automatique commandé par un automate. Le "AE-PLC-SCOR" comprend également un système de convoyeur pour transporter les pièces entrantes vers la zone de découpe où...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-FT

Usine-école de Filtration

The "AE-PLC-FT" is a filtration system commanded by a PLC. The "AE-PLC-FT" is composed of two tanks with a filter between them. The liquids are pumped from the first tank into the second tank through the filter using a pump and different types of...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-MS

Usine-école de Mélange

The "AE-PLC-MS" is a mixing system commanded by a PLC. The "AE-PLC-MS" is composed of three tanks with different liquids. These liquids are pumped and mixed in a reactor vessel using a pump and different valves. The system is equipped with flow...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-PHD

Usine-école de Poinçonnage

The "AE-PLC-PHD" is a processing workstation commanded by a PLC. This unit takes a piece and introduces it inside the punching zone that is protected with a polycarbonate screen. Once the piece is inside the punching zone, the hydraulic punching...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-FS

Usine-école de Remplissage

The "AE-PLC-FS" is a filling system commanded by a PLC. The workstation detects the bottles that arrive on a conveyor belt to the filling position and pumps liquids from a reservoir tank into the bottles using a pump and different types of valves....

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-CRS

Usine-école de Bouchage

The "AE-PLC-CRS" is a corking system commanded by a PLC. The workstation detects the bottles that arrives on a conveyor belt to the corking position and closes them with a cap using a pressing cylinder. The "AE-PLC-CRS" also includes different...

Qualité

Service après vente

Préférences sur les cookies

Préférences sur les cookies