CONTACTEZ-NOUS, POUR PLUS D'INFORMATIONS

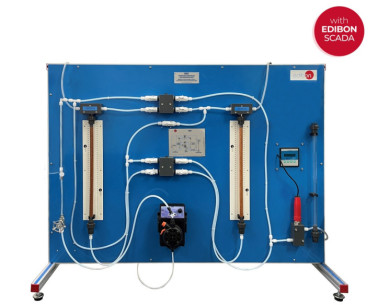

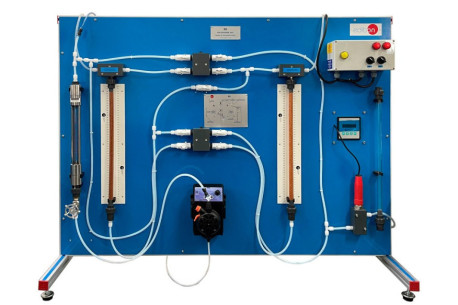

12.3.- TRAITEMENT D'EAU POTABLE

Eau potable, c'est-à-dire une eau propre à la consommation humaine est fondamentale dans toute civilisation. En outre, la demande en eau potable est en augmentation en raison de l'accroissement de la population et du développement industriel.

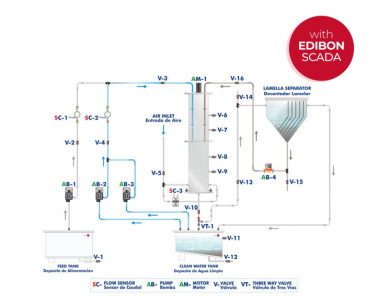

Voir plusL'eau potable est obtenue après avoir été soumise à une série de traitements physiques, chimiques et biologiques. Les stations de traitement d'eau potable (DWTP) sont créées grâce à ce besoin d'eau potable. Les principales étapes ou processus qui sont réalisés dans la STEP sont les suivants:

- Réception et homogénéisation de l'eau entrant dans le système.

- Prétraitement ou filtrage des matériaux grossiers: élimination des solides qui pourraient endommager l'installation.

- Processus de réaction avec ajout d'oxydants et coagulants. Cette étape permet d'éliminer les odeurs, les saveurs, les agents pathogènes et les matières inorganiques (minéraux) ou organiques (acides, nitrites, etc.). En fonction des contaminants, différentes techniques sont utilisées: aération, permanganate de potassium, chlore, etc.

- La sédimentation élimine les solides de plus petite taille encore contenus dans l'eau, en utilisant normalement des floculants.

- La filtration termine le processus de clarification après la sédimentation.

- Conditionnement. Un ajustement pH est effectué, parfois fluoration et désinfection pour tuer les pathogènes. Le fer et le manganèse sont également éliminés. Cette étape est essentielle car l'eau doit être analysée après les traitements et il faut vérifier que l'eau répond aux exigences légales pour l'approvisionnement.

- Stockage et fourniture d'eau traitée ou purifiée.

Aujourd'hui, les lois exigent toujours plus de qualité dans la purification de l'eau, de sorte que l'étude et la recherche continues des processus et des technologies pour le traitement de l'eau sont nécessaires.

Voir les produits Préférences sur les cookies

Préférences sur les cookies