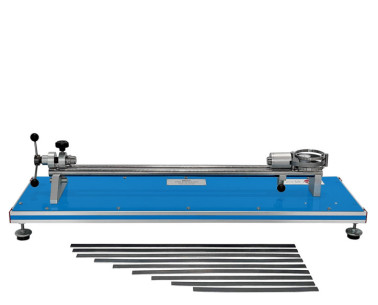

MUP Unité de Flambage Universelle

SYSTEMES INNOVANTS

L'Unité de Flambage Universelle, "MUP", a été conçu par EDIBON pour démontrer le concept de flambement des entretoises, qui permet de déterminer expérimentalement la relation entre la charge de flambement et les méthodes de support des barres d'essai, différentes épaisseurs et différentes formes des barres de test.

Expansions

Laboratories

NOUVELLES LIÉES

Description Générale

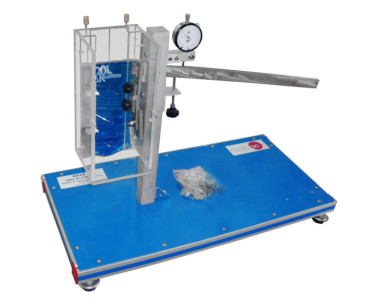

L'Unité de Flambage Universelle, "MUP", est une unité de table dont le cadre est constitué de profilés et de plaques en aluminium anodisé et d'éléments en acier, sur lequel un niveau à bulle est installé pour équilibrer le système.

L'unité a été conçue pour effectuer des tests avec différentes longueurs et différentes méthodes d'appui :

- Les deux extrémités épinglées.

- Les deux extrémités sont fixées.

- Une extrémité fixe et l'autre épinglée.

Cet unité est conçu pour fonctionner avec deux types de barres : de section circulaire et de section rectangulaire. Ainsi, les expérimentations peuvent être réalisées selon les différents modes d'appui et différentes longueurs, entre 400 mm et 800 mm.

L'ensemble dispose d'un écrou de réglage qui, associé à un niveau à bulle, permettra d'équilibrer les supports inférieurs horizontaux, tout cela après avoir soumis le système à la compression.

Il dispose d'un accessoire pour créer l'instabilité du système à étudier, qui se compose d'une poulie et de son support pour accrocher une masse. Cet accessoire permet de modifier la force perturbatrice qui agit sur une barre verticale soumise à compression.

Une balance numérique installée dans le portique latéral droit permettra de connaître la charge à laquelle la barre d'essai est soumise.

Pour obtenir la déflexion expérimentale de la barre d'essai, par rapport à la verticale, un comparateur à cadran est fourni.

Des exercices et pratiques guidées

EXERCICES GUIDÉS INCLUS DANS LE MANUEL

- Etude et vérification du théorème d'Euler sur le flambement.

- Détermination expérimentale de la relation entre la charge de flambement pour différentes épaisseurs et formes des barres d'essai.

- Détermination expérimentale de la relation entre la charge de flambement et les méthodes d'appui des barres d'essai.

- Détermination des différences de charges critiques pour différentes longueurs et différentes sections de barres.

- Mesure de la déviation latérale.

UNITÉS SIMILAIRES DISPONIBLES

Unité de Modes de Flambage d'Euler

EQUIPEMENT COMPLEMENTAIRE

Unité d' Essai Universel

Unité pour l'Essai de Dureté Brinell

Unité pour l'Essai de Dureté Brinell, Vickers et Rockwell

Unité pour l'Essai de Fluage

Unité d'Essai de Fatigue, Contrôlée par Ordinateur (PC)

Unité d'Essai de Fatigue

Unité d’Essai de Résilience Charpy et Izod

Unité d’Essai de Résilience Charpy et Izod de 300Nm

Unité de Flambement des Jambes de Force

Unité de Modes de Flambage d'Euler

Unité de Torsion et de Flexion

Unité de Torsion

Qualité

Service après vente

Préférences sur les cookies

Préférences sur les cookies