Chez EDIBON, nous sommes engagés à renforcer les compétences comme pilier stratégique pour la compétitivité et le bien-être social de l'Union européenne. Une formation adéquate renforce non seulement l'économie, mais permet également aux individus de participer pleinement à la société et à la...

0

Sélection

/

Vide

Votre sélection

Il n'y a plus d'articles dans votre sélection

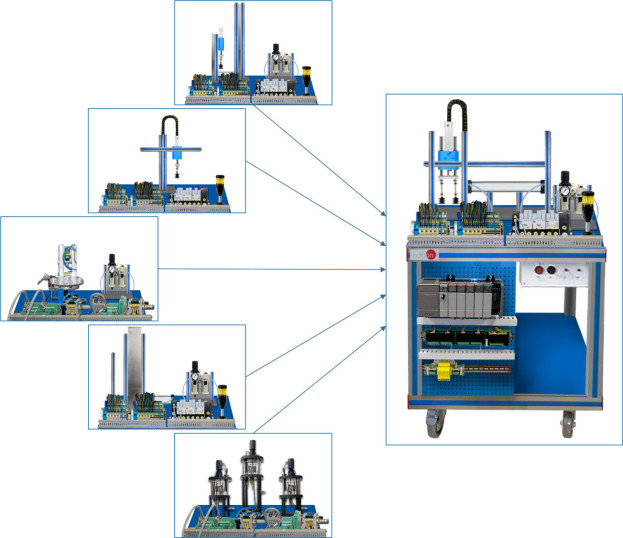

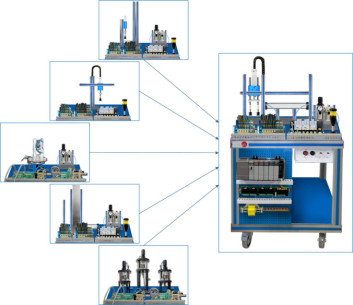

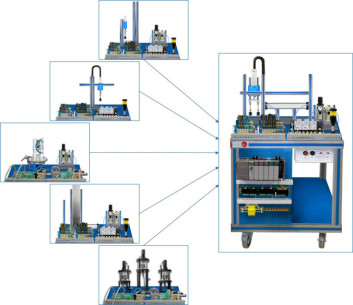

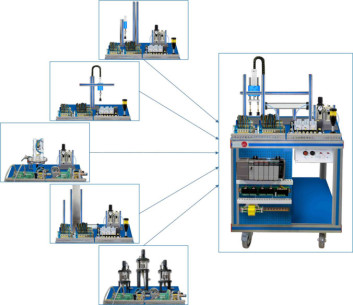

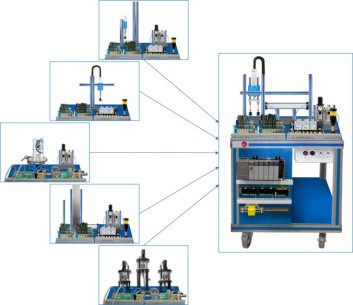

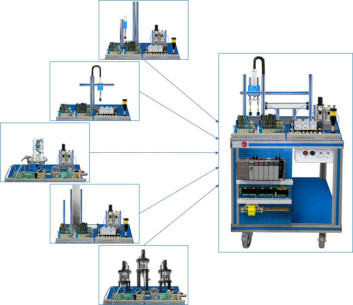

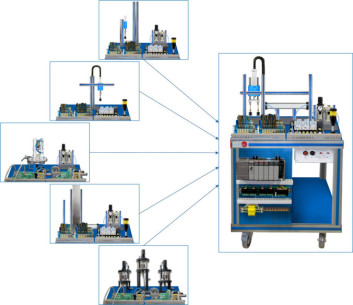

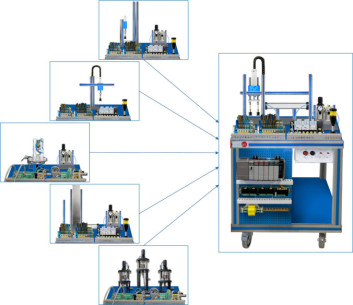

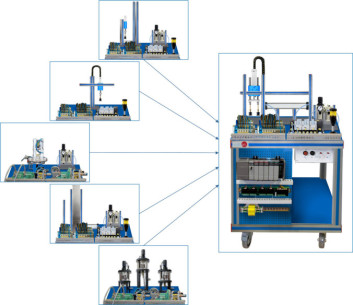

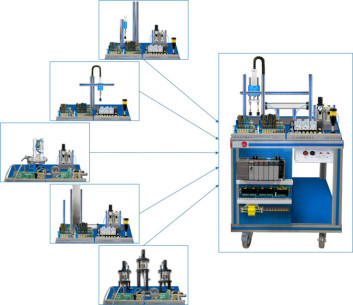

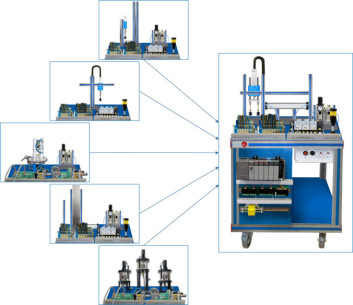

AE-PLC-P Usine-école de Pressage Automatique

SYSTEMES INNOVANTS

The "AE-PLC-P" workstation includes a set of practical exercises through which the student will understand how to control an automatic pressing system with a pneumatic handling system.

NOUVELLES LIÉES

Description Générale

The "AE-PLC-P" is an automatic pressing workstation commanded by a PLC. The "AE-PLC-P" moves the pieces from the input zone tothe pressing zone, once the piece is detected in the pressing zone, the "AE-PLC-P" emulates pressing the pieces with a hydraulic actuator.

The "AE-PLC-P" workstation is designed as a modular system to facilitate the understanding of the unit. The main components are:

- The PLC: is composed by the CPU limit and all extra modules needed to perform a corrent working of the workstation and all the extramodules needed to perform a correct working of the workstation.

- The control panel: with start/stop button, emergency pushbutton, reset button, light indicators to show current state of the process, etc.

- The pneumatic circuit: contains the required solenoid valves, the pressure components, the filters and regulators to assure the appropriate working of the unit.

- The Hydraulic circuit: contains the required solenoid valves, actuators, filters and regulators to assure the appropriate working of the unit.

- The workstation: is composed by real industrial components used by the industrial pressing systems with pneumatic manipulator suchas reed sensors, presence sensors, rotary actuators, vacuum cups, etc.

The "AE-PLC-P" is an independent workstation that can work alone and/or in conjunction with other workstation to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

Des exercices et pratiques guidées

EXERCICES GUIDÉS INCLUS DANS LE MANUEL

- Introduction to flexible manufacturing system (FMS).

- Introduction to pneumatics and electro-pneumatics.

- Introduction to hydraulics and electro-hydraulics.

- Introduction to vacuum technology.

- Study of the sensor detection.

- Configuration of a pneumatic application.

- Configuration of a hydraulic application.

- Manual control of a Pressing system.

- Automatic control of a Pressing system.

- Change the parameters of the Pressing process.

- Optimization of the process time.

- Study and analysis of the faults inserted in the process with the fault generation module.

UNITÉS SIMILAIRES DISPONIBLES

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-FT

The "AE-PLC-FT" is a filtration system commanded by a PLC. The "AE-PLC-FT" is composed of two tanks with a filter between them. The liquids are pumped from the first tank into the second tank through the filter using a pump and different types of...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-MS

Usine-école de Mélange

The "AE-PLC-MS" is a mixing system commanded by a PLC. The "AE-PLC-MS" is composed of three tanks with different liquids. These liquids are pumped and mixed in a reactor vessel using a pump and different valves. The system is equipped with flow...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-PHD

Usine-école de Poinçonnage

The "AE-PLC-PHD" is a processing workstation commanded by a PLC. This unit takes a piece and introduces it inside the punching zone that is protected with a polycarbonate screen. Once the piece is inside the punching zone, the hydraulic punching...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-FS

Usine-école de Remplissage

The "AE-PLC-FS" is a filling system commanded by a PLC. The workstation detects the bottles that arrive on a conveyor belt to the filling position and pumps liquids from a reservoir tank into the bottles using a pump and different types of valves....

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-CRS

Usine-école de Bouchage

The "AE-PLC-CRS" is a corking system commanded by a PLC. The workstation detects the bottles that arrives on a conveyor belt to the corking position and closes them with a cap using a pressing cylinder. The "AE-PLC-CRS" also includes different...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-APB

Usine-école d'Ouverture de Boîtes

The "AE-PLC-APB" is a bottles opening system commanded by a PLC. The unit is equipped with different containers and a retention system based on a cylinder, in order to allow the Robotic Arm Workstation "AE-BR" or the SCARA Arm Workstation "AE-SCA"...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-M

Usine-école de Montage

The "AE-PLC-M" is a mounting workstation commanded by a PLC that provides pieces to the system and mount them inside of the base pieces.The "AE-PLC-M" keeps the pieces in a vertical storage. The workstation take the pieces one by one, the quality...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-AT

Usine-école de Vissage Automatique

The "AE-PLC-AT" is an automatic screw workstation commanded by a PLC that supply and mount four screws in a piece. The "AE-PLC-AT" keeps the screws in a vertical storage. The workstation take the screws, one by one, and a pneumatic manipulator...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-MEMB

Usine-école d'Emballage

The Bottling Workstation, "AE-PLC-MEMB", designed by EDIBON, is an automatic rotary table with a vessel feeding system, a controlled water filling system, a cap feeder, a vessel closing system, and finally, an extraction system to a complete...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-MET

Usine-école d'Étiquetage

The "AE-PLC-MET" is an automatic labelling machine commanded by a PLC. The "AE-PLC-MET" also include a transporting system that carries the incoming bottles to the labelling zone, supplying the bottles one by one.The "AE-PLC-MET" workstation is...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-ST

Usine-école de Perçage

The "AE-PLC-ST" is an automatic drilling workstation commanded by a PLC. The "AE-PLC-ST" also include a conveyor system to transport the incoming pieces to the drilling zone where the drilling machine simulate the process.The "AE-PLC-ST"...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-SMOLD

Usine-école de Moulage

The "AE-PLC-SMOLD" is an automatic molding workstation commanded by a PLC. The "AE-PLC-SMOLD" also include a conveyor system to transport the incoming pieces to the molding zone where the unit simulate a molding process by punching the piece with...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-SCOR

Usine-école de Découpe

The "AE-PLC-SCOR" is an automatic cutting workstation commanded by a PLC. The "AE-PLC-SCOR" also includes a conveyor system to transport the incoming pieces to the cutting zone where the cutting machine simulate the process.The "AE-PLC-SCOR"...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-CP

Usine-école de Contrôle de Processus

The "AE-PLC-CP" is a process control workstation commanded by a PLC that coordinates the work of 3 industrial controllers that regulates in parallel the level, flow rate, temperature and pressure processes. The "AE-PLC-CP" workstation has been...

EQUIPEMENT COMPLEMENTAIRE

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-M

Usine-école de Montage

The "AE-PLC-M" is a mounting workstation commanded by a PLC that provides pieces to the system and mount them inside of the base pieces.The "AE-PLC-M" keeps the pieces in a vertical storage. The workstation take the pieces one by one, the quality...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-AT

Usine-école de Vissage Automatique

The "AE-PLC-AT" is an automatic screw workstation commanded by a PLC that supply and mount four screws in a piece. The "AE-PLC-AT" keeps the screws in a vertical storage. The workstation take the screws, one by one, and a pneumatic manipulator...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-MEMB

Usine-école d'Emballage

The Bottling Workstation, "AE-PLC-MEMB", designed by EDIBON, is an automatic rotary table with a vessel feeding system, a controlled water filling system, a cap feeder, a vessel closing system, and finally, an extraction system to a complete...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-MET

Usine-école d'Étiquetage

The "AE-PLC-MET" is an automatic labelling machine commanded by a PLC. The "AE-PLC-MET" also include a transporting system that carries the incoming bottles to the labelling zone, supplying the bottles one by one.The "AE-PLC-MET" workstation is...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-ST

Usine-école de Perçage

The "AE-PLC-ST" is an automatic drilling workstation commanded by a PLC. The "AE-PLC-ST" also include a conveyor system to transport the incoming pieces to the drilling zone where the drilling machine simulate the process.The "AE-PLC-ST"...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-SMOLD

Usine-école de Moulage

The "AE-PLC-SMOLD" is an automatic molding workstation commanded by a PLC. The "AE-PLC-SMOLD" also include a conveyor system to transport the incoming pieces to the molding zone where the unit simulate a molding process by punching the piece with...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-SCOR

Usine-école de Découpe

The "AE-PLC-SCOR" is an automatic cutting workstation commanded by a PLC. The "AE-PLC-SCOR" also includes a conveyor system to transport the incoming pieces to the cutting zone where the cutting machine simulate the process.The "AE-PLC-SCOR"...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-FT

Usine-école de Filtration

The "AE-PLC-FT" is a filtration system commanded by a PLC. The "AE-PLC-FT" is composed of two tanks with a filter between them. The liquids are pumped from the first tank into the second tank through the filter using a pump and different types of...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-MS

Usine-école de Mélange

The "AE-PLC-MS" is a mixing system commanded by a PLC. The "AE-PLC-MS" is composed of three tanks with different liquids. These liquids are pumped and mixed in a reactor vessel using a pump and different valves. The system is equipped with flow...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-PHD

Usine-école de Poinçonnage

The "AE-PLC-PHD" is a processing workstation commanded by a PLC. This unit takes a piece and introduces it inside the punching zone that is protected with a polycarbonate screen. Once the piece is inside the punching zone, the hydraulic punching...

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-FS

Usine-école de Remplissage

The "AE-PLC-FS" is a filling system commanded by a PLC. The workstation detects the bottles that arrive on a conveyor belt to the filling position and pumps liquids from a reservoir tank into the bottles using a pump and different types of valves....

6.2.5.2.- TRAITEMENT DES APPLICATIONS DE POSTES DE TRAVAIL

AE-PLC-CRS

Usine-école de Bouchage

The "AE-PLC-CRS" is a corking system commanded by a PLC. The workstation detects the bottles that arrives on a conveyor belt to the corking position and closes them with a cap using a pressing cylinder. The "AE-PLC-CRS" also includes different...

Qualité

Service après vente

Préférences sur les cookies

Préférences sur les cookies