Une fois de plus, EDIBON a eu l’honneur de participer à l’un des événements internationaux les plus importants dans le domaine de l’enseignement en ingénierie : l’ASEE Annual Conference and Exposition 2025, organisée par l’American Society for Engineering Education (ASEE).

Chez EDIBON, nous sommes engagés à renforcer les compétences comme pilier stratégique pour la compétitivité et le bien-être social de l'Union européenne. Une formation adéquate renforce non seulement l'économie, mais permet également aux individus de participer pleinement à la société et à la...

Dans un monde où la demande en énergie ne cesse d'augmenter et où les ressources non renouvelables s'épuisent rapidement, la nécessité de trouver des solutions durables et respectueuses de l'environnement n'a jamais été aussi urgente. L'économie circulaire et l'utilisation de la biomasse...

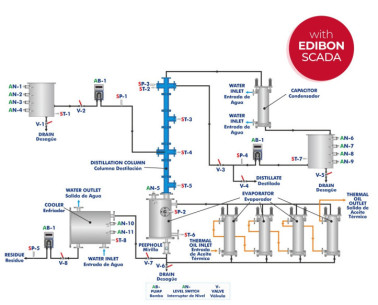

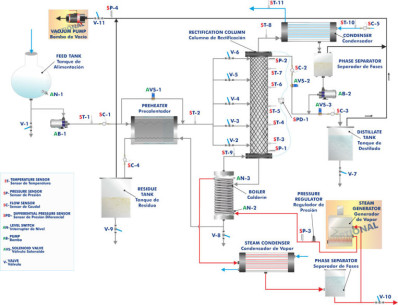

Today we would like to tell you about our latest installation in Indonesia. At Institut Teknologi Sepuluh Nopember we have installed the following equipment. Our engineers came to the centre to install the equipment and explain how it works to the people responsible for using it.

Préférences sur les cookies

Préférences sur les cookies