Une fois de plus, EDIBON a eu l’honneur de participer à l’un des événements internationaux les plus importants dans le domaine de l’enseignement en ingénierie : l’ASEE Annual Conference and Exposition 2025, organisée par l’American Society for Engineering Education (ASEE).

Dans un monde où le changement climatique représente l’une des plus grandes menaces pour notre avenir, l’adsorption du dioxyde de carbone (CO₂) est devenue une priorité urgente. L’augmentation de la concentration de CO₂ dans l’atmosphère, principalement due aux activités humaines telles que la...

Chez EDIBON, nous sommes engagés à renforcer les compétences comme pilier stratégique pour la compétitivité et le bien-être social de l'Union européenne. Une formation adéquate renforce non seulement l'économie, mais permet également aux individus de participer pleinement à la société et à la...

Dans un monde où la demande en énergie ne cesse d'augmenter et où les ressources non renouvelables s'épuisent rapidement, la nécessité de trouver des solutions durables et respectueuses de l'environnement n'a jamais été aussi urgente. L'économie circulaire et l'utilisation de la biomasse...

La Captation Directe de l'Air (DAC) est une technologie innovante qui élimine le CO₂ directement de l'air en utilisant des réactions chimiques avec des solvants liquides ou des absorbants solides. Malgré des défis tels que des coûts élevés et une consommation d'énergie importante, la DAC offre...

Installations de Traitement des Eaux Usées

Alors que les usines de traitement de l'eau potable se concentrent sur la fourniture d'eau potable sûre, les installations de traitement des eaux usées gèrent le traitement de l'eau usée avant qu'elle ne soit à nouveau libérée dans l'environnement.

Ces...

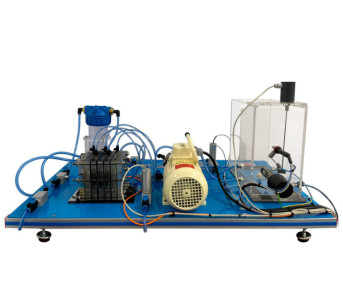

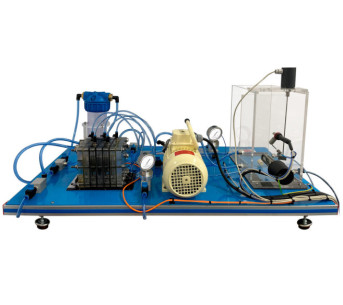

We want to present the latest installation that we have made in the Chemical Engineering Department of Al-Balqa Applied University Polytechnic (BAU), in Salt (Jordania). It was a pleasure!

We are grateful for the trust of UPC - Universidad Peruana de Ciencias Aplicadas that has allowed us to install seven units [EBGC, EFLP, EII, PDAC, PDS, PEAI, PEF] to help future engineers to understand in a simpler way everything related to #environmental engineering

Préférences sur les cookies

Préférences sur les cookies