PPFAC Unité de Traitement des Boues Actives, Contrôlée par Ordinateur (PC)

SYSTEMES INNOVANTS

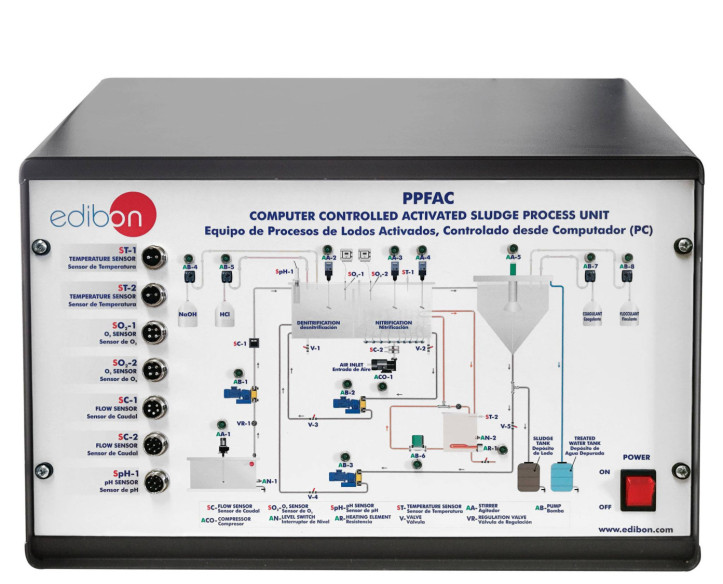

L’Unité de Traitement des Boues Actives, Contrôlée par Ordinateur (PC), "PPFAC", conçue par EDIBON, permet de simuler le fonctionnement d’une station d’épuration des eaux usées, en dégradant les composants organiques de l’eau à l’aide de cultures de micro-organismes aérobies (boues activées).

Expansions

Laboratories

NOUVELLES LIÉES

Description Générale

L’Unité de Traitement des Boues Actives, Contrôlée par Ordinateur (PC), "PPFAC", conçue par EDIBON, permet de simuler le fonctionnement d’une station d’épuration des eaux usées, en dégradant les composants organiques de l’eau à l’aide de cultures de micro-organismes aérobies (boues activées).

L’unité est monté sur un cadre métallique et se compose de deux modules reliés par un ensemble de tuyaux (inclus).

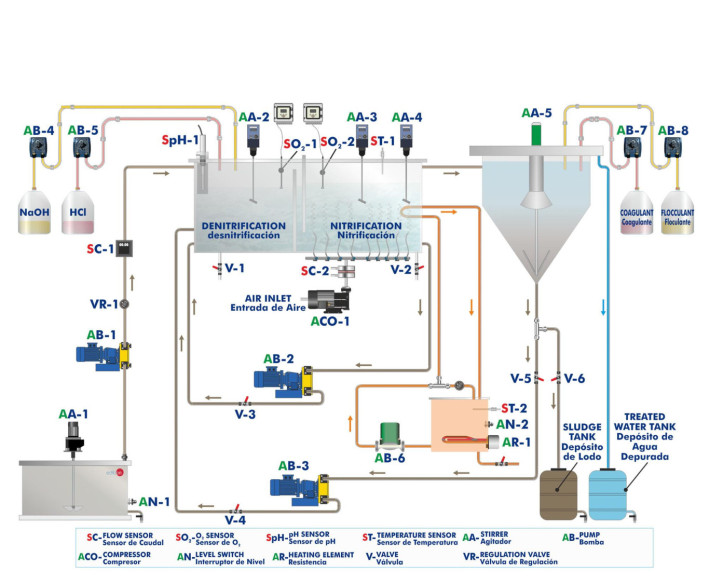

Le premier module consiste en un réservoir d’alimentation en eau brute contenant des matières organiques dissoutes. Le mélange est constamment agité par deux agitateurs commandés par ordinateur.

Le second module comprend le réservoir de traitement de l’eau contenant les micro-organismes des boues activées, un décanteur et d’autres éléments nécessaires au traitement des eaux usées.

L’eau brute est pompée du réservoir d’alimentation vers le réservoir de traitement de l’eau à l’aide d’une pompe commandée par ordinateur, où elle est mélangée aux boues activées contenant des micro-organismes.

L’air est fourni au réservoir de traitement de l’eau par un compresseur commandé par ordinateur.

Le réservoir est divisé en deux zones séparées par un mur : une zone de nitrification (l’ammonium est oxydé en nitrate en présence d’air) et une zone de dénitrification (le nitrate est réduit en azote moléculaire sans la présence d’air). L’eau brute est maintenue mélangée aux boues activées au moyen de trois agitateurs commandés par ordinateur.

La concentration en oxygène, le pH et la température peuvent être modifiés par ordinateur (PC) :

- La valeur du pH de l’eau brute peut être modifiée en ajoutant de l’acide et de la base à l’aide de deux pompes péristaltiques à vitesse réglable, ce qui permet d’étudier la valeur du pH dans le processus des boues activées.

- La valeur de la concentration en oxygène dans la zone de nitrification du réservoir peut être modifiée en régulant l’alimentation en air du compresseur d’entrée du réservoir.

- La température peut être modifiée au moyen d’un circuit d’échange de chaleur. Une résistance électrique chauffe l’eau contenue dans un réservoir (avec interrupteur de niveau et robinet de vidange), qui est acheminée par une pompe à travers un circuit qui transfère sa chaleur à la zone de nitrification.

À la sortie de la cuve, le mélange passe dans un décanteur où l’eau est séparée des boues activées qui se déposent au fond et dont une partie est renvoyée dans la cuve de traitement de l’eau par une pompe commandée par ordinateur. Dans ce bassin de décantation, un coagulant (pour réduire les forces de répulsion entre les particules) et un floculant (pour la formation de flocs plus importants) sont appliqués au moyen de deux pompes péristaltiques à vitesse réglable commandées par ordinateur (PC).

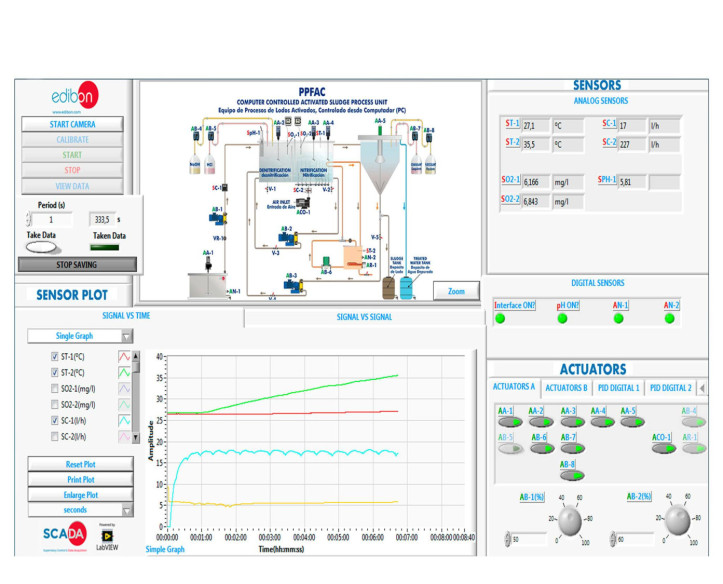

Cette Unité Contrôlée par Ordinateur est fournie avec le Système de Contrôle par Ordinateur EDIBON (SCADA), et comprend : l'Unité elle-même + un Boîtier d'Interface de Contrôle + une Carte d'Acquisition de Données + des Progiciels de Contrôle par Ordinateur, d'Acquisition de Données et de Gestion de Données, pour contrôler le processus et tous les paramètres impliqués dans le processus.

Des exercices et pratiques guidées

EXERCICES GUIDÉS INCLUS DANS LE MANUEL

- Etalonnage des pompes péristaltiques.

- Étude du traitement des eaux usées par boues activées.

- Étude des processus de nitrification et de dénitrification.

- Etude de l’influence de la valeur de la concentration en oxygène dans la dégradation biologique.

- Etude microbiologique d’un bouillon actif.

PLUS D'EXERCICES PRATIQUES À EFFECTUER AVEC CETTE ÉQUIPEMENT

- Etude de l’influence des boues de retour.

- Manipulation de l’unité afin d’obtenir un fonctionnement stable.

- Étude de l’âge des boues et de son influence sur le processus.

- Étude des résultats lorsque le débit massique des boues activées varie.

- Etude des résultats lorsque la charge volumétrique de l’eau brute varie.

- Etude de l’influence du ratio de boues de retour de recirculation interne pour la dénitrification préalable.

- Calcul de l’efficacité de la dénitrification préalable.

- Étude de l’influence du pH sur la dégradation biologique.

- Étude de l’influence de la température sur la dégradation biologique.

- Étude de l’influence de la concentration en oxygène sur la dégradation biologique.

- Étalonnage des capteurs.

Autres possibilités à réaliser avec cette unité :

- De nombreux étudiants voient les résultats simultanément. Pour voir tous les résultats en temps réel dans la classe au moyen d'un projecteur ou d'un tableau blanc électronique.

- Contrôle ouvert, multicontrôle et contrôle en temps réel. Cette unité permet intrinsèquement et/ou extrinsèquement de changer la durée, les gains, paramètres proportionnels, intégraux, dérivés, etc. en temps réel.

- Le système de contrôle informatique avec SCADA et Contrôle PID permet une véritable simulation industrielle.

- Cette unité est totalement sûre car elle utilise des dispositifs de sécurité mécaniques, électriques et électroniques.

- Cette unité peut être utilisée pour faire de la recherche appliquée.

- Cette unité peut être utilisée pour donner des cours de formation aux industries même à d'autres institutions d'enseignement technique.

- Contrôle du processus de l'unité PPFAC via la boîte d'interface de contrôle sans l'ordinateur.

- Visualisation de toutes les valeurs de capteurs utilisées dans le processus de l'unité PPFAC.

- En utilisant PLC-PI, 19 autres exercices peuvent être effectués.

- Plusieurs autres exercices peuvent être faits et conçus par l'utilisateur.

EQUIPEMENT COMPLEMENTAIRE

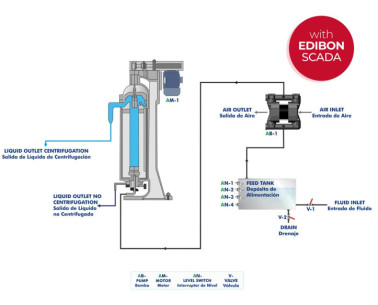

Séparateur Centrifuge Semi-continu de 1000 L, Contrôlé depuis Ordinateur (PC) et Écran Tactile

Digesteur Aérobie, Contrôlé par Ordinateur (PC)

Digesteur Aérobie

Digesteur Anaérobie, Contrôlé par Ordinateur (PC)

Digesteur Anaérobie

Unité de Floculation, Contrôlée par Ordinateur (PC)

Unité de Floculation

Unité d´Aération, Contrôlée par Ordinateur (PC)

Unité d´Aération

Unité de Filtration à Lit Profond, Contrôlée par Ordinateur (PC)

Unité de Filtration à Lit Profond

Qualité

Service après vente

Préférences sur les cookies

Préférences sur les cookies