HEMP Pressure Measurement Unit

INNOVATIVE SYSTEMS

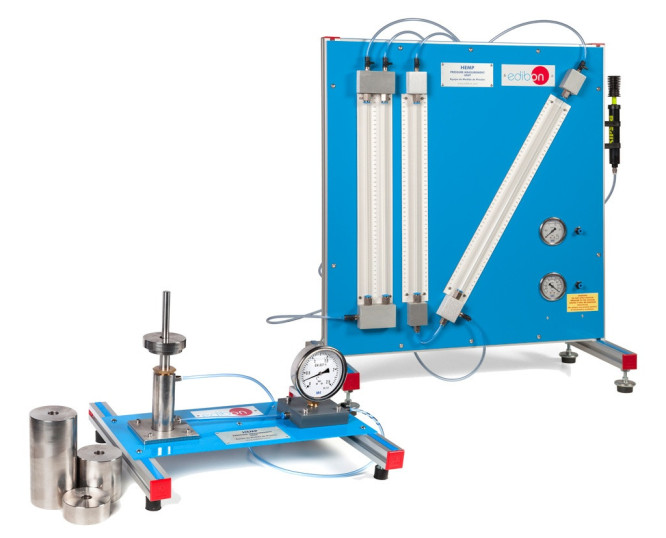

The Pressure Measurement Unit, "HEMP", designed by EDIBON, allows to study pressure measurement techniques widely, since different manometers can be used to understand and compare the operation characteristics of the different devices and to study their calibration principles.

Laboratories

RELATED NEWS

General Description

The Pressure Measurement Unit, "HEMP", enables a wide range of investigations and studies into pressure measurement techniques, using Bourdon type manometers and different U-tube manometers, to understand the operation, the characteristics of the devices, and to study the principles of calibration and to do practical exercises and experiments about it.

The "HEMP" unit mainly consists of:

- Vertical "U" type manometer (direct measurement).

- Inclined "U" manometer (direct measurement).

- Positive pressure Bourdon manometer (indiret measurement).

- Negative pressure Bourdon manometer (indiret measurement).

In addition, the unit includes a Dead Weight Calibrator, "FME10". It consists of a cylinder with a sliding precision piston fitted inside. A mass calibrated system is added to generate a certain amount of preset pressures inside the cylinder. The Bourdon manometer, whose correct operation has to be checked beforehand with the aid of the piston and masses, is connected to the cylinder through a flexible tube.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Familiarisation with different pressure measurement methods.

- Study of the function and characteristics of a Bourdon type manometer.

- Study of the function and characteristics of an "U" tube manometers.

- Pressure measurements with Bourdon type manometers. Indirect measurement.

- Pressure measurements with vertical or inclined U-tube manometers. Direct measurement.

- Comparison between the different methods of pressure measurement.

- Calibration of a pressure gauge.

- Determination of measurement errors.

- Checking the readings of a Bourdon type manometer using a calibrated standard set of masses.

- Determination of the hysteresis curve of a manometer.

SUPPLEMENTARY EQUIPMENT

Drop Ball Viscometer and Resistance Coefficient Determination Unit

Precision Pressure Gauge Calibrator

Pressure Measurement and Calibration Unit

Pressure Sensors Calibration System

Manometers & Multimanometers (several types):

U-Shape Double Manometer

U-Shape Manometer

Inclined Multimanometer with 20 manometric tubes of 250 mm length

Multimanometer with 8 manometric tubes of 500 mm length, vertical position

Multimanometer with 12 manometric tubes of 500 mm lenght, vertical position

4 Bourdon type Manometers Unit

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences