Chez EDIBON, nous sommes engagés à renforcer les compétences comme pilier stratégique pour la compétitivité et le bien-être social de l'Union européenne. Une formation adéquate renforce non seulement l'économie, mais permet également aux individus de participer pleinement à la société et à la...

0

Sélection

/

Vide

Votre sélection

Il n'y a plus d'articles dans votre sélection

AE-PLC-MACT Usine-école Pneumatique de Manipulation et Bande Transporteuse

SYSTEMES INNOVANTS

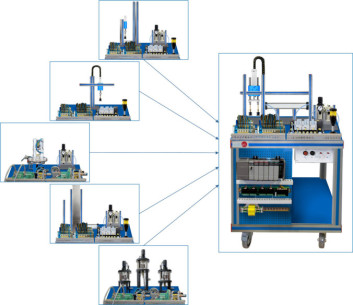

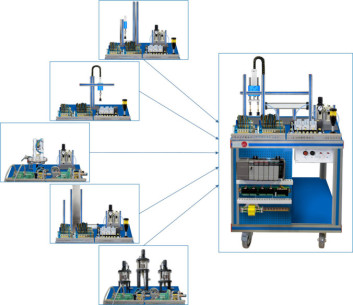

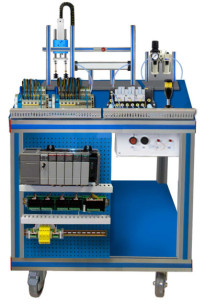

La Usine-école Pneumatique de Manipulation et Bande Transporteuse, "AE-PLC-MACT", a été conçue par EDIBON pour permettre aux étudiants de se familiariser avec les systèmes automatiques avec les systèmes de convoyage, y compris les PLC, les capteurs industriels et les actionneurs pneumatiques.

NOUVELLES LIÉES

Description Générale

Le Station de Manutention Pneumatique et Ruban de Transportn, "AE-PLC-MACT" est une station de manutention automatique avec système de convoyeur commandé par un PLC. Le "AE-PLC-MACT" est composé d'un système de manutention pneumatique qui utilise la technologie du vide pour déplacer les pièces de la zone d'entrée des pièces au système de convoyeur ou viceversa.

La station pneumatique "AE-PLC-MACT" se compose de :

- Convoyeur à bande CC avec servomoteur, qui permet de contrôler la vitesse, la position et le sens de rotation.

- Capteurs de pièces pour détecter la pièce et arrêter la courroie pour placer une autre pièce.

- Système pneumatique de déplacement de pièces utilisant la technologie du vide pour les saisir.

- PLC qui automatise le processus.

- Interrupteur à clé amovible pour allumer ou éteindre l'unité.

- Panneau de commande avec interrupteur d'arrêt de type champignon, boutons d'arrêt et de démarrage, mode manuel et automatique, voyants lumineux.

Des exercices et pratiques guidées

EXERCICES GUIDÉS INCLUS DANS LE MANUEL

- Introduction au Système de Fabrication Flexible (FMS).

- Introduction à la pneumatique et à l'électropneumatique.

- Configuration d’une application pneumatique.

- Introduction à la technologie du vide.

- Etude de la détection du capteur.

- Contrôle manuel d'un système de manutention.

- Contrôle automatique d'un système de manutention.

- Modification des paramètres du processus de manipulation.

- Etude et analyse des défauts insérés dans le processus avec le module de génération de défauts.

PLUS D'EXERCICES PRATIQUES À EFFECTUER AVEC CETTE ÉQUIPEMENT

- Optimisation du temps de traitement.

UNITÉS SIMILAIRES DISPONIBLES

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MAE

The "AE-PLC-MAE" is an electrical handling system commanded by a PLC. The "AE-PLC-MAE" is composed of a two axis electrical manipulator with a pneumatic gripper to transport the pieces from the input pieces holder to the corresponding position,...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MAN

Usine-école Pneumatique de Manipulation

The "AE-PLC-MAN" is a pneumatic handling workstation commanded by a PLC, which performs handling and sorting functions.The workstation identify the color of the input pieces at the input pieces area, once the color is identified, the station take...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MPS

Usine-école de Manipulation des Pièces

The "AE-PLC-MPS", Pieces Manipulator Workstation, is a unit that works with pneumatics, electro-pneumatics and vacuum technologies.The "AE-PLC-MPS" performs the following operation: moving a piece from one position to another by using suction pads...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-T

Usine-école de Transport Linéaire

The "AE-PLC-T" is a linear transporting system, which moves the pallets, that carries the pieces, along the system. The unit is configured in a closed loop conveyor powered by an electrical motor, the whole system is commanded by a PLC. The...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-SPO

Usine-école de Positionnement

Le Usine-école de Positionnement, "AE-PLC-SPO", conçue par EDIBON, est une usine-école de positionnement contrôlée par PLC qui vérifie le matériau et les dimensions des pièces entrantes pour les trier en trois emplacements...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-CTCA

Usine-école de Bande Transporteuse CA

The "AE-PLC-CTCA" is an AC powered conveyor system commanded by a PLC. The "AE-PLC-CTCA" is composed by a conveyor, 4 position sensors to stop the conveyor at different positions, motor positioner, AC motor driver and three-phased motor to a...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-CTCC

Usine-école de Bande Transporteuse CC

Le Usine-école de Bande Transporteuse CC, "AE-PLC-CTCC", conçue par EDIBON, est un système de convoyage CC contrôlé par PLC qui vérifie le matériau des pièces entrantes pour les classer en deux sorties différentes.Le "AE-PLC-CTCC" se compose d'une...

EQUIPEMENT COMPLEMENTAIRE

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MPS

Usine-école de Manipulation des Pièces

The "AE-PLC-MPS", Pieces Manipulator Workstation, is a unit that works with pneumatics, electro-pneumatics and vacuum technologies.The "AE-PLC-MPS" performs the following operation: moving a piece from one position to another by using suction pads...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-T

Usine-école de Transport Linéaire

The "AE-PLC-T" is a linear transporting system, which moves the pallets, that carries the pieces, along the system. The unit is configured in a closed loop conveyor powered by an electrical motor, the whole system is commanded by a PLC. The...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-SPO

Usine-école de Positionnement

Le Usine-école de Positionnement, "AE-PLC-SPO", conçue par EDIBON, est une usine-école de positionnement contrôlée par PLC qui vérifie le matériau et les dimensions des pièces entrantes pour les trier en trois emplacements...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MAE

Usine-école Électrique de Manipulation

The "AE-PLC-MAE" is an electrical handling system commanded by a PLC. The "AE-PLC-MAE" is composed of a two axis electrical manipulator with a pneumatic gripper to transport the pieces from the input pieces holder to the corresponding position,...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-MAN

Usine-école Pneumatique de Manipulation

The "AE-PLC-MAN" is a pneumatic handling workstation commanded by a PLC, which performs handling and sorting functions.The workstation identify the color of the input pieces at the input pieces area, once the color is identified, the station take...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-CTCA

Usine-école de Bande Transporteuse CA

The "AE-PLC-CTCA" is an AC powered conveyor system commanded by a PLC. The "AE-PLC-CTCA" is composed by a conveyor, 4 position sensors to stop the conveyor at different positions, motor positioner, AC motor driver and three-phased motor to a...

6.2.5.4.- STATIONS DE TRAVAIL DE MANIPULATIONS DE PIECES

AE-PLC-CTCC

Usine-école de Bande Transporteuse CC

Le Usine-école de Bande Transporteuse CC, "AE-PLC-CTCC", conçue par EDIBON, est un système de convoyage CC contrôlé par PLC qui vérifie le matériau des pièces entrantes pour les classer en deux sorties différentes.Le "AE-PLC-CTCC" se compose d'une...

Qualité

Service après vente

Préférences sur les cookies

Préférences sur les cookies