The Microgrid Power Systems training equipment, "AEL-MGP," has been designed by EDIBON for theoretical and practical education on microgrid power systems. In today’s global context, microgrids play a crucial role in the transformation of the energy system. These infrastructures enable the local integration of renewable energy sources, intelligent demand management, and energy storage, facilitating autonomy and continuity of supply even during failures or disconnections from the main grid. Additionally, they contribute significantly to reducing greenhouse gas emissions and democratizing energy access, especially in rural or isolated areas. Consequently, EDIBON has meticulously developed the "AEL-MGP" system to address this educational and technological need. It is a comprehensive, hands-on teaching tool that allows users to simulate, analyze, and understand the real operation of a hybrid microgrid.

EDIBON’s commitment to educational innovation is reflected in every detail of the "AEL-MGP": its modular architecture, use of industrial-scale components, equipment robustness and safety, over 70 practical possibilities, and adaptability to specific curricula or research projects. Through the "AEL-MGP" application, instructors and professionals can work with advanced concepts such as island control, hierarchical energy management (energy mix), dynamic stability, power quality, black start protocols, reverse power flow studies, power balance and flow analysis, blackout scenarios, and the implementation of Grid-Forming and Grid-Following control modes, among many others.

Ultimately, this system is not only part of the energy transition but also trains those who will lead it.

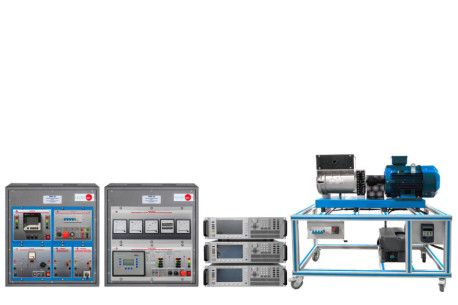

- PWP-CE. Conventional Energy Power Plant.

Its function, as in a real micro grid, is to serve as the structural base of the system and to establish voltage and frequency references. The rest of the power plants synchronize to it due to the stability it provides.

Additionally, this application serves as base generation, supplying continuous power. In real micro grids, this corresponds to diesel or gas generation. The setup includes a turbine-generator group composed of an electric motor (simulating the turbine) mechanically coupled to a three-phase synchronous generator for electricity generation. A multifunction digital controller (AVR and ASC) is used to manage the turbine-generator set, enabling precise control of both electrical and mechanical parameters.

The key control parameters include turbine speed, generator frequency, excitation current, voltage, and generator power (active P, reactive Q, and apparent S). This control module also provides advanced generator and turbine protections, adhering to ANSI standards such as ANSI 81O, 81U, 59, 27, 50/51, 32R/F, IOP 32, MOP 32, 46, voltage asymmetry, generator ground fault, phase rotation, IEC 255, and lagging power factor, among others. The setup also includes smart metering-compliant network analyzers for monitoring generated and consumed energy, with two-way communication to optimize system management.

- PWP-HE. Hydroelectric Power Plants.

The purpose of this application is to study hydroelectric plants in the context of micro grids. Hydroelectric power plants have a large capacity to supply energy at certain times of peak demand due to their rapid response. Therefore, this application consists of a turbinegenerator group whose purpose is to supply energy to the micro grid, performing intelligent energy distribution based on the decisions of the operator (user).

The application includes a network analyzer to measure the energy produced by the hydroelectric plant in real time. A multifunction digital controller (AVR and ASC) is included to control the turbine-generator unit, allowing for optimal regulation of all its electrical and mechanical parameters. Among many other parameters, it is possible to control the generator’s active power "reference point" to automatically regulate how much active power we want to inject into the micro grid. The multifunction controller is of vital importance, as it is responsible for managing the distribution of power between the different generators in the micro grid.

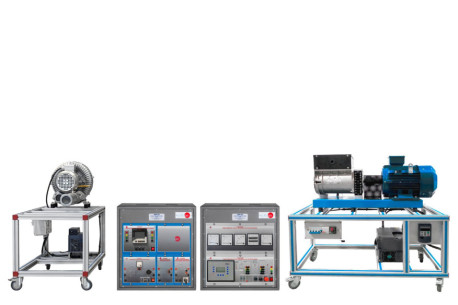

- PWP-WE. Wind Power Plants.

The purpose of this application is to study wind power plants in the context of micro grids. It consists of an induction turbine-generator unit whose purpose is to supply energy to the micro grid by intelligently distributing energy based on the operator’s (user’s) decisions. To this end, the application includes a network analyzer to measure the energy produced by the wind farm in real time.

A multifunction digital controller (AVR and ASC) is included to control the turbine-generator unit, allowing for optimal regulation of all its electrical and mechanical parameters. Among many parameters, it is possible to control the active power "reference point" to automatically select how much power we want to inject into the micro grid.

- PWP-PE. Phototvoltaic Power Plants.

The purpose of this application is to study photovoltaic power plants in the context of micro grids.

It has a three-phase inverter powered by a photovoltaic panel array simulator. The user can configure the generation parameters and functions of the photovoltaic simulator according to the scenarios and conditions to be studied. At the same time, the user can study important concepts related to photovoltaic installations, such as the MPPT (maximum power point tracking) characteristic, the power limitation of an inverter (derating), the efficiency of an inverter, and reactive power generation.

- PWP-BE. Batteries Energy Storage Power Plant.

The purpose of this application is to demonstrate the importance of energy storage in isolated environments. There are cases in which, due to the absence of wind or photovoltaic energy, we have no choice but to resort to chemical energy storage by means of batteries.

This application consists of a bidirectional inverter whose purpose is to store energy in a battery, also included, and to quickly supply that energy when demand requires it. The advantage of this type of application is that, as it involves power electronics, it has a high response speed. This gives power plants such as hydroelectric or wind farms enough time to react to sudden changes in demand. During periods of energy overproduction, the batteries use this surplus to store it.

- PWP-FE. Flywheel Storage Power Plant.

The purpose of this application is to demonstrate the importance of energy storage in isolated environments.

In this case, it is a sophisticated application responsible for storing kinetic energy by means of a flywheel. It has a bidirectional converter that allows energy to be taken from the micro grid and then returned at specific moments of need. The advantage of this type of application is that, as it involves power electronics (bidirectional converter), it has a high response speed. This gives power plants such as hydroelectric or wind farms enough time to react to sudden changes in demand.

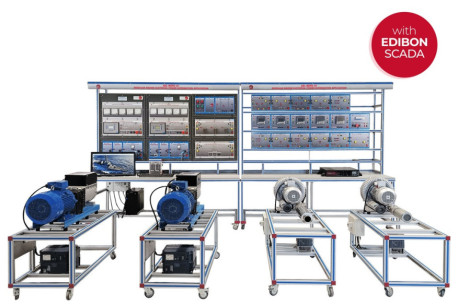

The Microgrid Power System "AEL-MGP" consists of a set of required and recommended modules for studying the various scenarios encountered in a microgrid:

- The "Conventional Energy Power Plant", "PWP-CE": Is primarily required due to the low inertia provided by renewable energies. Therefore, there is a need to supply inertia through synchronous generation, such as conventional power plants.

- EDIBON proposes a set of recommended modules (at least one required) to allow users to select those best suited for their study scenarios.

The "AEL-MGP" application includes a real-time supervision, control, and data acquisition SCADA software (EMG-SCADA), designed to represent and manage microgrid operations. It enables remote and centralized management of each generation plant (conventional and renewable), energy storage, and system loads. Key features include configuration of plant parameters, adjustment of frequency (f), voltage (V), and power (P) setpoints, automatic grid synchronization, energy quality monitoring, system load flow tracking, and creation of dynamic demand and renewable resource profiles. Thanks to its intuitive graphical interface and high interactivity, the SCADA system allows the simulation of real operational scenarios, faults, imbalances, and energy optimization strategies, making it an essential tool for both technical training and validation of complex electrical systems.

Cookie preferences

Cookie preferences