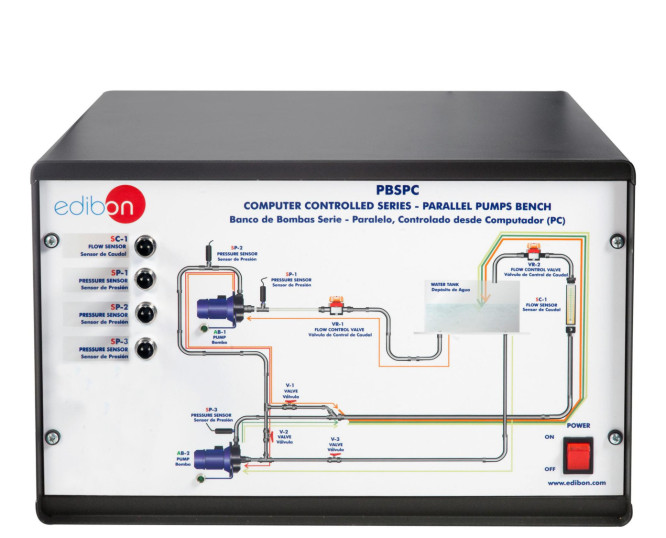

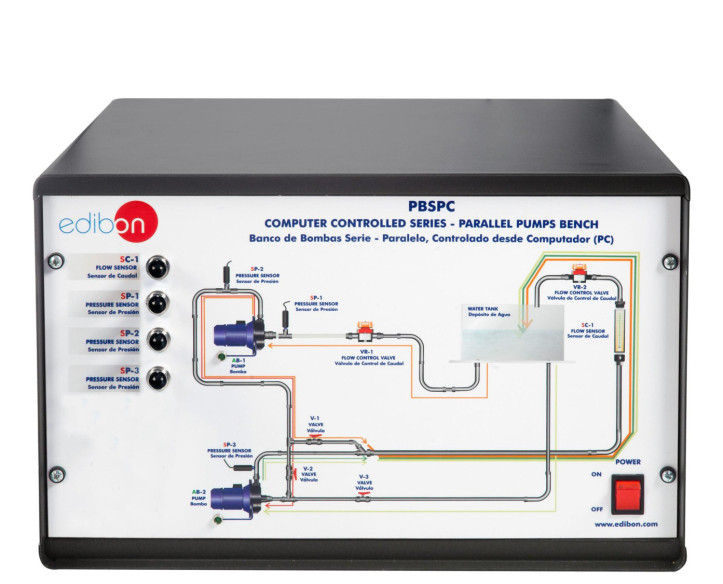

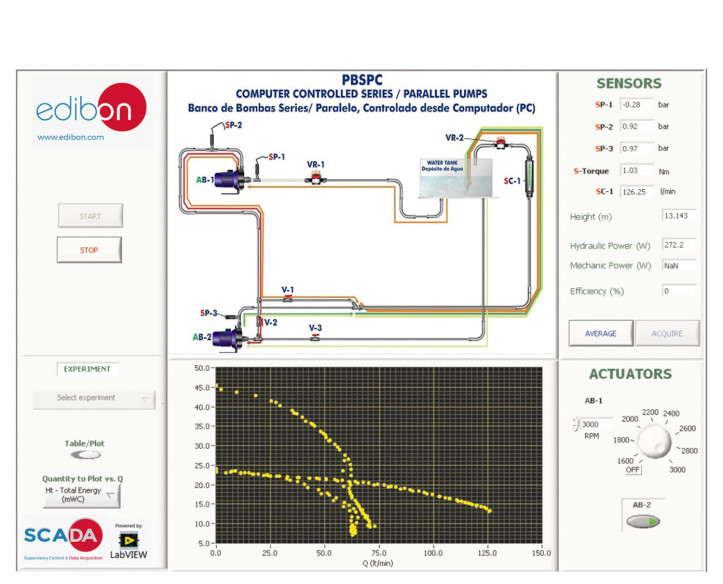

PBSPC Computer Controlled Series/Parallel Pumps Bench

INNOVATIVE SYSTEMS

The Computer Controlled Series/Parallel Pumps Bench, "PBSPC", has been designed by EDIBON to demonstrate the operational advantages of parallel or series operation, depending on the required duty.

Expansions

Laboratories

RELATED NEWS

General Description

The Computer Controlled Series/Parallel Pumps Bench, "PBSPC", has been designed by EDIBON to demonstrate the operational advantages of parallel or series operation, depending on the required duty.

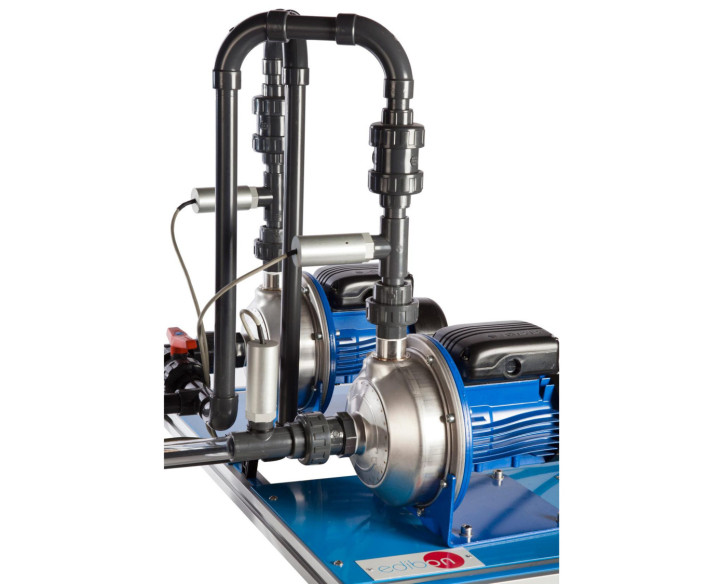

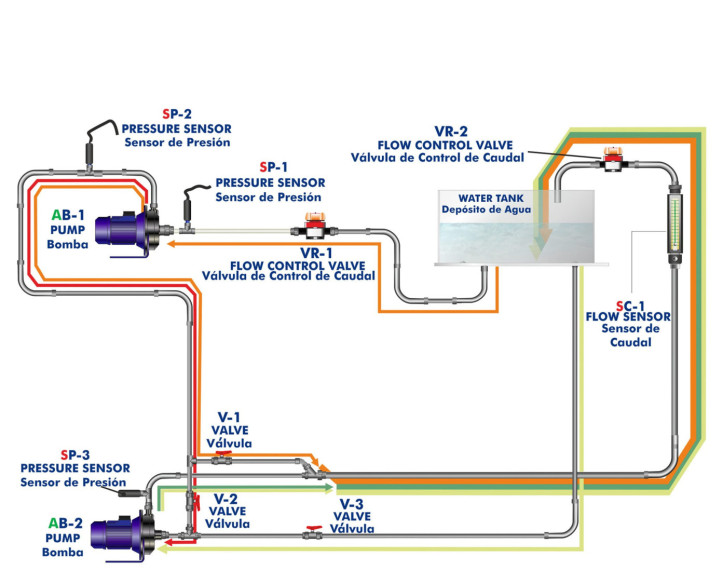

This unit consists of two centrifugal pumps, a feed water tank, circulation pipes, regulation valves, three pressure sensors and a flow sensor.

The centrifugal pumps can operate: alone, coupled in series or in parallel. A three-phase motor activates a pump with possibility of adjustment and measurement of the turn speed as well as the transmitted mechanic torque, and a single-phase motor activates the other pump.

The pumps are installed in a pipes system, which, as it is a closed circuit, avoids the permanent waste of water during the operation.

By the appropriate positioning of the valves it is possible to connect the pumps individually, in series or in parallel, depending on which test is going to be performed.

The "PBSPC" unit has instrumentation and sensors to allow the measurement, from the computer, of the most typical parameters of the pumps:

- Motor turn speed.

- Total impelled flow.

- The admission and discharge pressure.

- Torque.

- Calculated values:

- Total height.

- Hydraulic power.

- Mechanic power.

- Efficiency.

Adjustable parameters, as:

- Motor speed and flow.

- Position of the valves.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Obtaining curves H (Q), N (Q), Eff% (Q).

- Three simultaneous representations of H (Q), N (Q) and Eff% (Q).

- Obtaining the map of a centrifugal pump.

- Adimensional study of magnitudes H*, N* and Q*.

- Cavitation test and obtaining curves NPSHr.

- Series coupling of two pumps with same characteristics.

- Series coupling of two pumps of different characteristics.

- Parallel coupling of two pumps with same characteristics.

- Parallel coupling of two pumps of different characteristics.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Sensors calibration.

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PBSPC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PBSPC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SIMILAR UNITS AVAILABLE

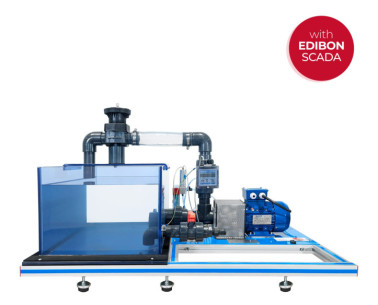

Centrifugal Pump Characteristics

Series/Parallel Pumps Bench

SUPPLEMENTARY EQUIPMENT

Computer Controlled Multipump Testing Bench (4 types of pumps)

Computer Controlled Multipump Testing Bench (2 types of pumps)

Series/Parallel Pumps Bench

Computer Controlled Gear Pump Bench

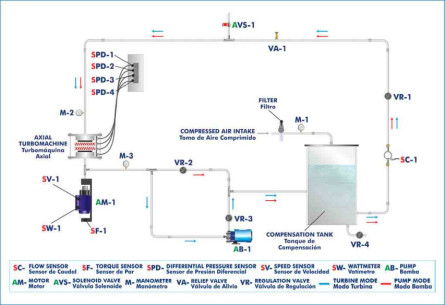

Computer Controlled Axial Pump Bench

Computer Controlled Piston Pump Bench

Computer Controlled Axial Flow Turbomachines Unit

Pumps Alignment and Study Bench

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences