PPBC Computer Controlled Biofilm Process Unit

INNOVATIVE SYSTEMS

The Computer Controlled Biofilm Process Unit, "PPBC", has been designed by EDIBON to study the operation of a trickling filter, which removes microorganisms and filters contaminated water. The unit simulates the treatment given to water in a wastewater treatment plant.

Expansions

Laboratories

RELATED NEWS

General Description

The Computer Controlled Biofilm Process Unit, "PPBC", has been designed by EDIBON to study the operation of a trickling filter, which removes microorganisms and filters contaminated water. The unit simulates the treatment given to water in a wastewater treatment plant.

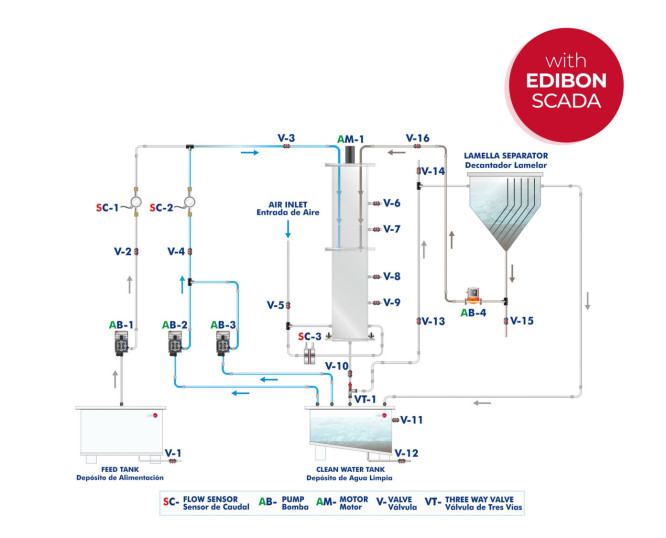

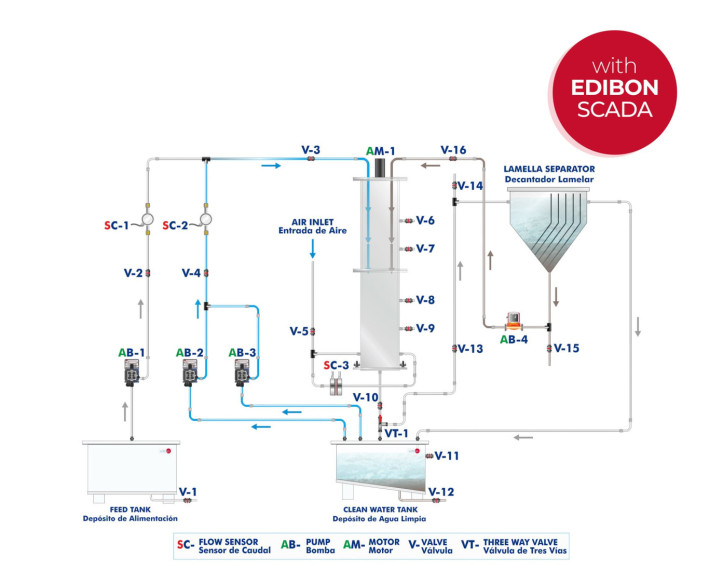

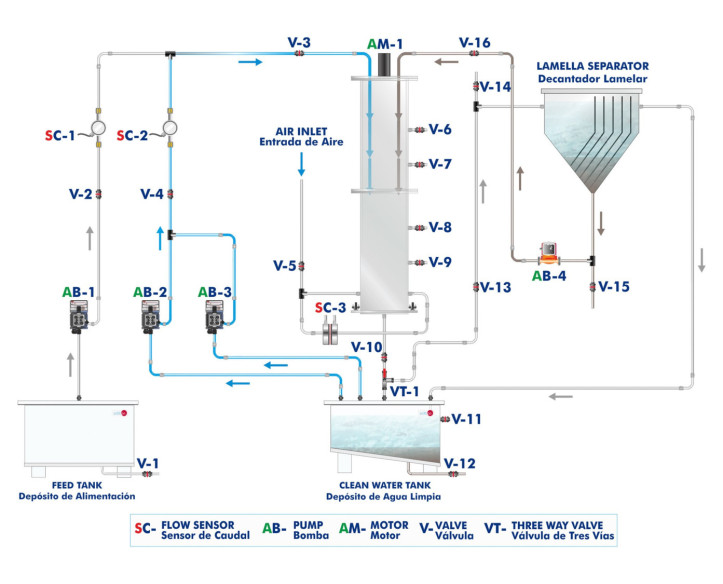

The main element of the unit is the trickling filter. To produce the biofilm, the filter must be filled with carrier material, wastewater and activated sludge before starting the process. When the process starts, the wastewater is impelled by a computer controlled pump, reaching the top of the trickling filter. Once there, it is scattered by a rotary distributor and drops down to the carrier material. A biofilm (a layer of microorganisms nourished from water organic contaminants) grows in this material.

Both the breakdown of biological components and water nitrification take place in the trickling filter. Afterwards, wastewater goes to a collection tank, one part is recycled with the aid of two computer controlled pumps and returns to the trickling filter inlet. Activated sludge leaving the filter goes to a clarifier that separates it from water. Clean water goes to the collection tank and the activated sludge goes back to the top of the filter with the aid of a computer controlled pump.

The filter must be aerated during the process to prevent unpleasant odors. Aeration can take place by natural convection, thanks to the orifices at the bottom of the filter, or with an air compressor.

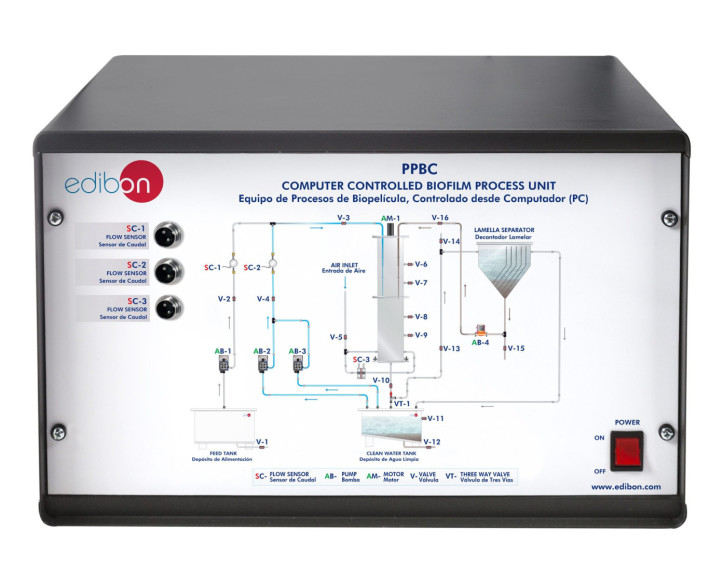

There are several flow measurement points at key points of the circuit (at the raw water inlet, water recycling and compressed air inlet). In addition, the speed of the rotary motor and the flow at the different points can be controlled from the computer and the flow, speed and concentration values can be recorded throughout the circuit.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Studying and understanding the functions of a trickling filter.

- Operation of the unit to achieve stable working conditions.

- Study of the unit operation depending on the recirculation flow rate.

- Study of the unit operation depending on the volumetric loading of the filter.

- Study of the unit operation depending on the surface loading of the filter.

- Concentration profiles recording.

- Influence of the carrier material on the results.

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PPBC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PPBC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SUPPLEMENTARY EQUIPMENT

Computer Controlled and Touch Screen 1000 l Semicontinuous Centrifugal Separator

Computer Controlled Aerobic Digester

Aerobic Digester

Computer Controlled Anaerobic Digester

Anaerobic Digester

Computer Controlled Flocculation Test Unit

Flocculation Test Unit

Computer Controlled Aeration Unit

Aeration Unit

Computer Controlled Deep Bed Filter Unit

Deep Bed Filter Unit

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences