PEAC Computer Controlled Adsorption Unit

INNOVATIVE SYSTEMS

The Computer Controlled Adsorption Unit, "PEAC", has been designed by EDIBON to study and precisely characterize the behavior of adsorption of dissolved substances on activated carbon using columns in series, analyzing the influence of operating variables such as flow rate, adsorbate concentration, and temperature.

Expansions

Laboratories

RELATED NEWS

General Description

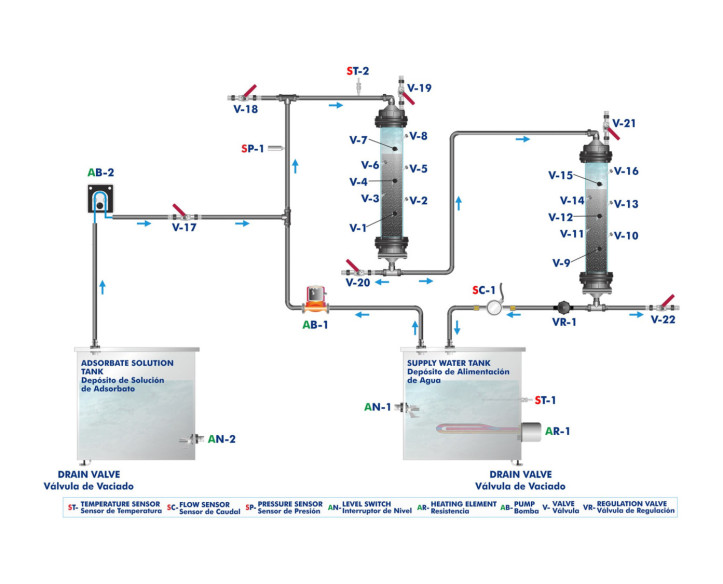

The Computer Controlled Adsorption Unit, "PEAC", designed by EDIBON, enables the detailed study of the adsorption process in physico-chemical water treatment systems, accurately reproducing the behavior of two activated carbon columns arranged sequentially. The unit allows research on mass transfer between the liquid and solid phases, the construction of breakthrough curves, and the evaluation of adsorbent efficiency under different operating conditions.

This unit provides a practical approach for both training and research, allowing real-time observation of how adsorbate concentration, contact time, temperature effects, and flow rate influence the saturation of activated carbon. Computer-controlled operation facilitates continuous monitoring of the critical process parameters and enhances experimental repeatability.

The design of the unit integrates a stainless-steel feed tank with a heating system, enabling the study of temperature influence on adsorption kinetics and capacity. The dosed addition of the adsorbate, performed by a computer-controlled peristaltic pump, makes it possible to set the inlet concentration precisely. The hydraulic circuit incorporates a main pump, also computer-controlled, together with a flow sensor for monitoring the operating conditions.

The process takes place in two transparent, removable adsorbers containing the activated carbon. Each column includes multiple sampling ports distributed along its height, enabling characterization of the concentration profile evolution and the advance of the mass-transfer zone. The valve system allows the selection of open- or closed-loop operation, modifying the residence time and the number of passes through the adsorbent bed.

The unit includes temperature sensors at relevant points of the process, as well as level switches for safe operation of both tanks. All main components are mounted on a robust benchtop structure with wheels for mobility, a front panel with a functional diagram, and stainless-steel metallic elements for durability and ease of maintenance.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Study and analysis of the adsorption process of substances dissolved in activated carbon.

- Influence of raw water temperature in the adsorption process.

- Influence of the contact time between raw water and adsorbent in the adsorption process.

- Influence of the operation mode in the adsorption process.

- Influence of adsorbate concentration in the adsorption process.

- Efficiency of an adsorber.

- Mass balance of an adsorber.

- Representation of concentration profiles and rupture curves.

- Relationship between concentration profiles and rupture curves.

- Study of the mass transfer zone.

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PEAC unit process through the control interfacebox without the computer.

- Visualization of all the sensors values used in the PEAC unitprocess.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SUPPLEMENTARY EQUIPMENT

Gas Absorption Column

Double Column Gas Absorption Unit

Computer Controlled Wetted Wall Gas Absorption Column

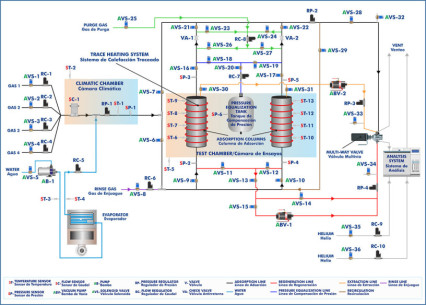

Laboratory Scale Pressure Swing Adsorption Unit

Computer Controlled Fixed Bed Adsorption Unit

Computer Controlled Adsorptive Air Drying Unit

Computer Controlled Gas Washing Processing Plant

Computer Controlled Unit to Study Flow through Packed Columns

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences