CAGC Computer Controlled Gas Absorption Column

INNOVATIVE SYSTEMS

The Computer Controlled Gas Absorption Column, "CAGC", is a laboratory scale unit designed to study hydrodynamic and absorption processes in a packed column.

Expansions

Laboratories

RELATED NEWS

General Description

The Computer Controlled Gas Absorption Column, "CAGC", is a scale unit designed to study hydrodynamic and absorption processes in packed columns. This system absorbs ammonia or CO2 from a mixture with air in a watery solution that flowing down the column.

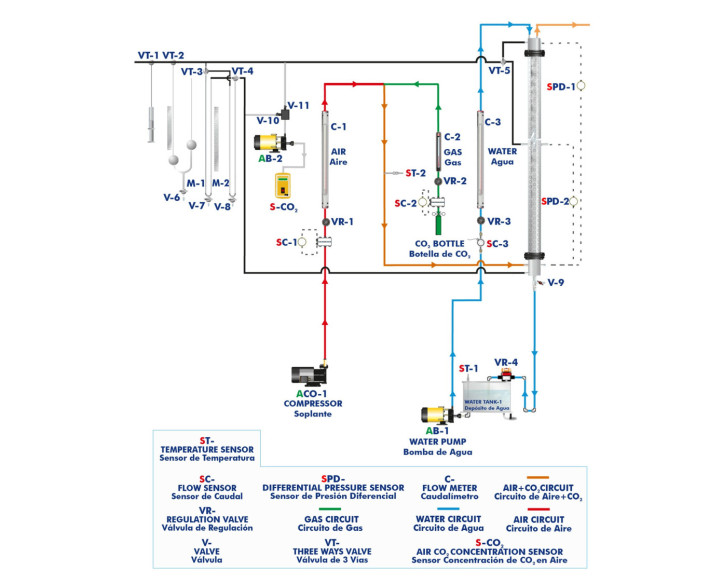

The main parts of the unit are:

- Packed column: it consists of a glass cylindrical column filled with Raschig rings. Two differential pressure sensors measure the pressure in different parts of the column.

- Liquid circuit (water): the liquid, that is stored in a PVC tank, is impelled towards the column by a pump. It feeds the column through its upper end using a glass diffusion shower. After crossing the column, the liquid is returned to the storage tank. The liquid flow that arrives to the column is measured by a flow sensor and a flowmeter. In the storage tank, through aeration, the CO2 can be desorbed from the liquid previously filled in the column.

- Gas circuit (air and CO2): it consists of a CO2 and air (supplied by a blower) mixture current. Both gaseous currents are mixed, and later they enter the base of the column through a side inlet located below the bed level, so that the gaseous mixture is an homogeneous as possible. Both gas flows are measured by sensors and flowmeters.

- CO2 measuring system: it allows to determine the concentration of this gas in the currents originated from the upper and central parts of the column. The measurement can be performed analytically or directly with the CO2 sensor.

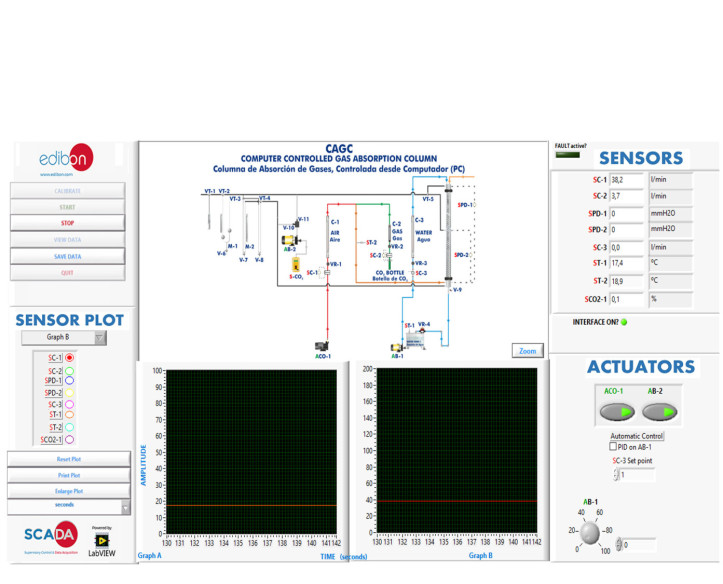

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Study of the basic principles of the absorption of a gas into a liquid using a packed column.

- Gas stream analysis.

- Study of the hydrodynamic characteristics of a packed column.

- Determination of the drag and flooding flows.

- Determination of the mass transfer coefficient.

- Checking of the mass balances.

- Demonstration of methods of gas and liquid quantitative analysis.

- Investigations of the variables influencing the efficiency of the absorption.

- Measurement of the CO2 concentration in gaseous currents using a CO2 sensor.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- PID control system.

- Study of the hysteresis in the water flow sensor.

- Sensors calibration.

- Determination of the water, CO2 and air flow.

- Head loss in the column.

- Influence of temperature on the adsorption efficiency.(It requires the optional accessory TERA/A).

- Study of the simple desorption process.

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control.This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the CAGC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the CAGC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

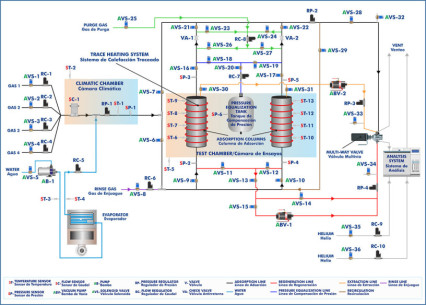

SIMILAR UNITS AVAILABLE

SUPPLEMENTARY EQUIPMENT

Gas Absorption Column

Double Column Gas Absorption Unit

Computer Controlled Wetted Wall Gas Absorption Column

Laboratory Scale Pressure Swing Adsorption Unit

Computer Controlled Fixed Bed Adsorption Unit

Computer Controlled Adsorptive Air Drying Unit

Computer Controlled Gas Washing Processing Plant

Computer Controlled Unit to Study Flow through Packed Columns

Computer Controlled Adsorption Unit

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences