The Laboratory Scale Pressure Swing Adsorption Unit, "LPSA", is a laboratory scale plant that allows the performance of adsorption tests using the pressure swing technique.

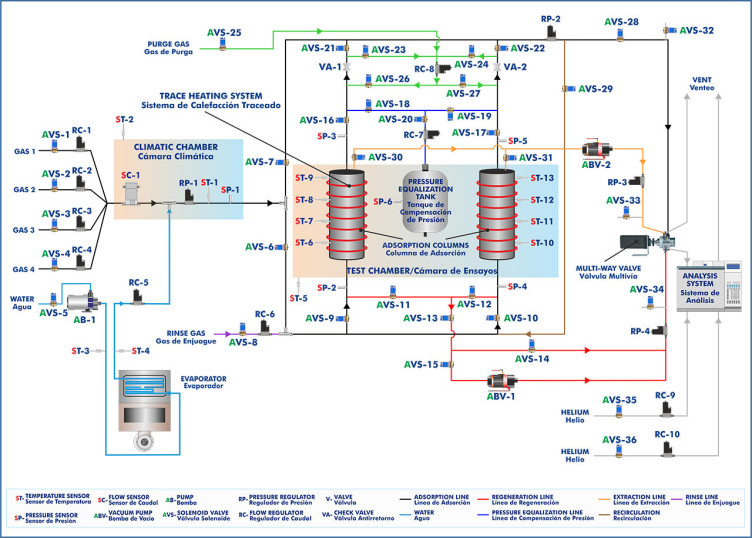

The LPSA unit allows to synthesize a mixture of gases coming from four different cylinders controlling the flow of each one of them. In this way, an enormous variety of feed streams might be created varying the concentration of the different species and its flow rate. In addition, it is possible to inject water vapor to evaluate the influence of humidity in the subsequent adsorption process.

The adsorption process is carried out in two columns in parallel which allows for more efficient operation. Adsorption is a discontinuous process because when the adsorbent in the column becomes saturated it is necessary to stop the feed current and perform the bed regeneration. Therefore, having two columns in parallel it is possible that one of the columns performs the adsorption operation while the other one performs the desorption. The adsorption columns and the pressure compensation tank are placed inside a climatic chamber that controls the temperature at which the test is performed.

While operation, the first step is the pressurization of the bed, for which the feed is input to the desired column until it reaches the working pressure. Once this happens, the effluent is started to be conducted to the analysis equipment. While in the first column the adsorption is performed, in the second column the desorption takes place. It is possible to recirculate part of the effluent from the column that operates in adsorption to be used as a purge in the column in desorption. When the column reaches its break point, the feed and effluent line are closed and the depressurization is performed up to atmospheric pressure.

Before depressurization, it is possible to perform a flushing stage and then a pressure compensation stage in which the gas accumulated in that column is used to perform a partial pressurization of the other column or to fill a pressure compensation tank. Finally, the bed is regenerated at low pressure and in countercurrent by passing a purge current or by applying a vacuum. Afterwards, in the pressure compensation stage, part of the effluent from adsorption or the gas contained in the compensation tank can be passed through this column thus improving the recovery of the product of interest and reducing the amount of gas lost in depressurization. This process is performed cyclically in both columns allowing a continuous operation if the break and regeneration times of the adsorbent allow it.

To complete the regeneration of the adsorbent it is possible to perform its degassing by subjecting the sample to high temperatures and a high vacuum level. For this purpose, the columns is equipped with a heating tracing system that allows to raise its temperature and a vacuum system that allows to purge the desorbed gas.

This Computer Controlled Equipment is supplied with EDIBON Computer Control System (SCADA), and includes: the Equipment itself + a Control Interface Box + a Data Acquisition Card + Control, Data Acquisition and Data Management Software Packages, for the control of the process and all parameters involved in the process.

Cookie preferences

Cookie preferences