At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

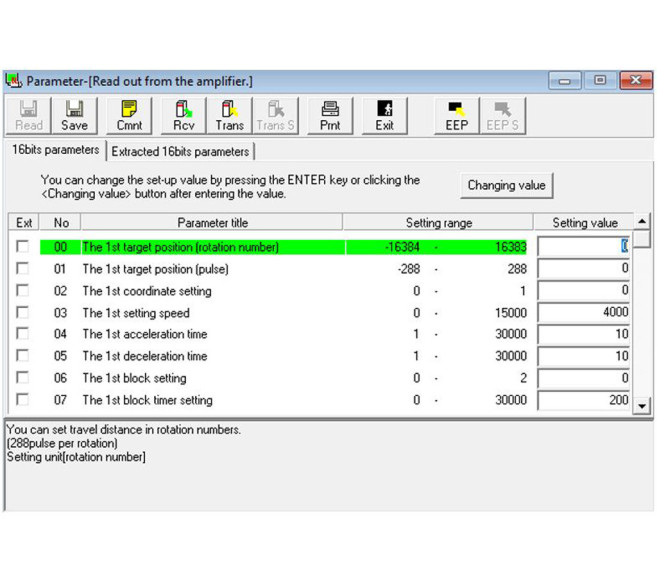

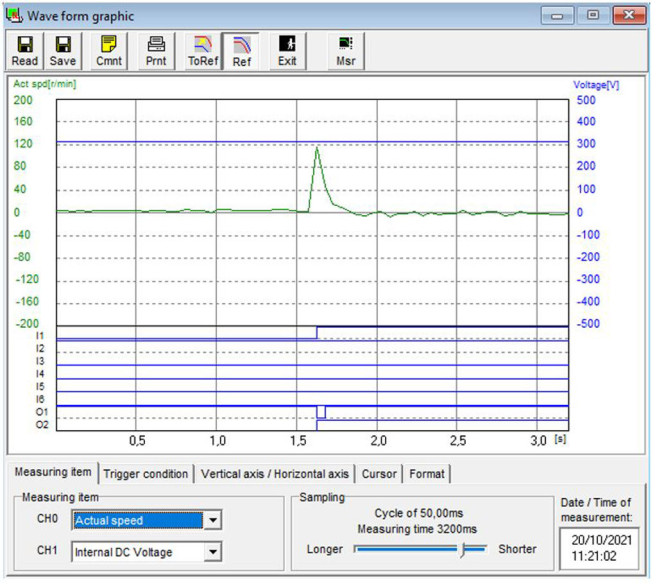

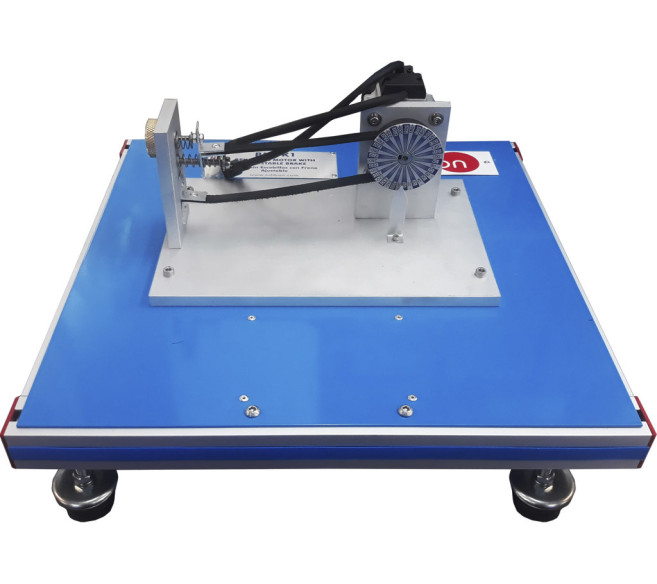

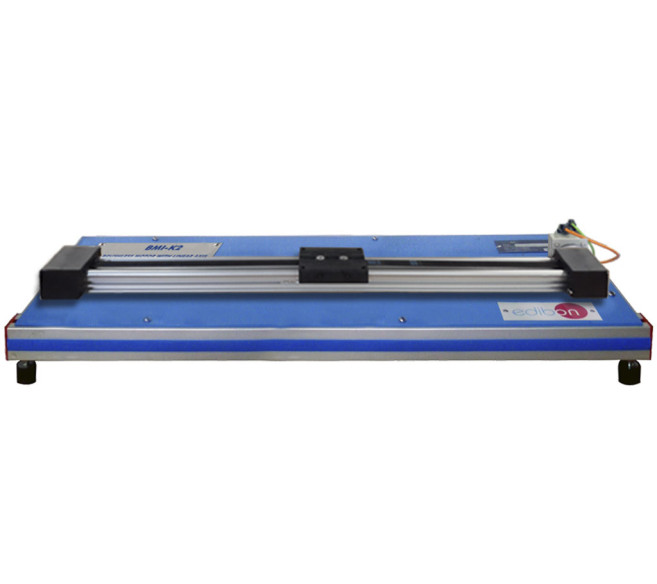

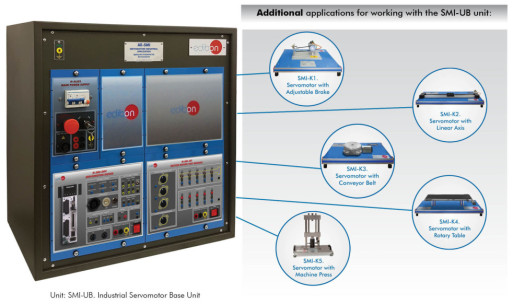

The Industrial Application of Brushless Motors (AE-BMI), has been designed by EDIBON to study the control system of a brushless DC motor with a real application. It contains available applications containing industrial systems as a linear axis system or a DC motor with a braking system. All this...

On December 1st, the Repair Course for Small Laboratory Equipment, taught by our engineers at the EDIBON facilities, was completed, lasting 4 days.

The attendees, (Laboratory technicians and maintenance of the Rey Juan Carlos University of Madrid) had the opportunity to perform multiple...

Cookie preferences

Cookie preferences