FOR FURTHER INFORMATION, CONTACT US

7.2.- AUTOMOTIVE MECHANICAL ENGINEERING

The automotive industry is one of the main applications of current mechanical engineering. The vehicle with gasoline internal combustion engine is considered the greatest invention of the 20th century, although the first prototypes were already made at the end of the 18th century. The first prototype dates from 1769. It was a steam carriage. It was not successful but it set the precedents for the development of the gasoline engine in 1860. From this discovery, an unstoppable development began and automotive industries like Benz, Peugeot, Fiat or Ford proliferated. With the turn of the millennium, the use of other fossil fuels, such as diesel, began to be investigated.

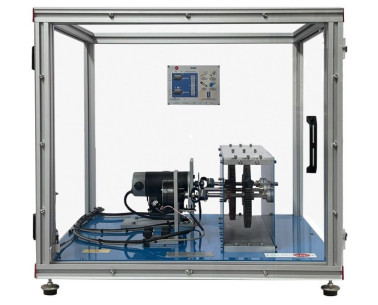

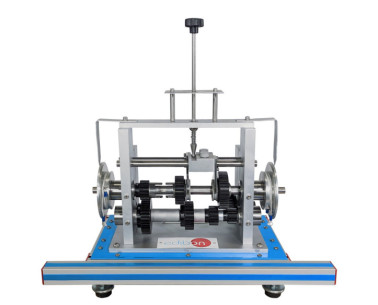

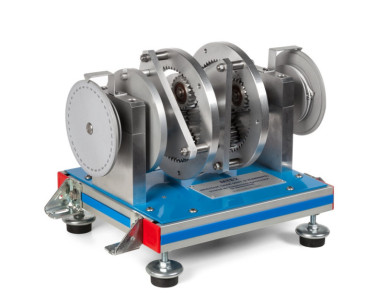

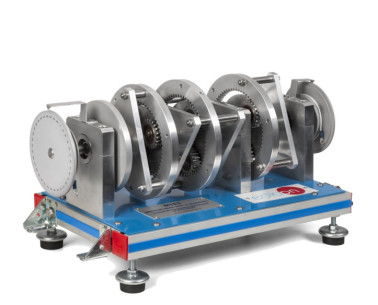

View moreNowadays, using all the available technology and means, one can get to know the behavior of all the elements that make up a vehicle in an infinite number of situations. This level of knowledge is possible thanks to the engineering behind each design, analysis, etc. Some of the most studied systems are:

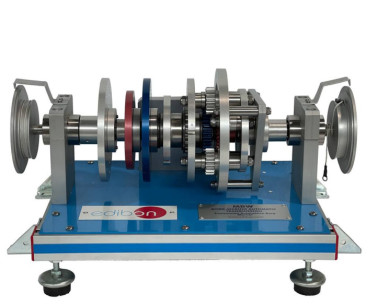

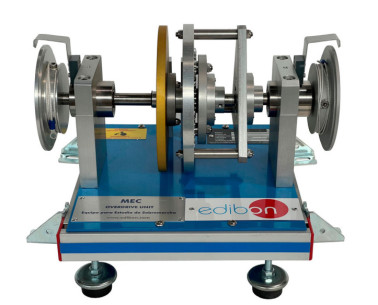

- Transmission.

- Brakes.

- Suspension.

- Engine performance.

- Electronics.

- Emissions.

- Safety.

The industries related to the automotive sector have to be continuously upgraded, researching and applying all the technical advances at their reach to be competitive and to satisfy the needs of today's society. The trend in this sector is the search for more sustainable and environmentally friendly sources of energy, as well as more efficient designs with higher performance, which have become a reality with the appearance of hybrid and electric vehicles and vehicles propelled by other fuels, such as liquefied petroleum gas (LPG) or hydrogen.

View Products Cookie preferences

Cookie preferences