At EDIBON, we have completed a new installation at the Department of Civil Engineering at the Papua New Guinea University of Technology (PNGUOT). This...

Water is an essential resource for human life, economic development, and the planet’s ecological balance. However, as we move deeper into the 21st...

Water is an essential resource for human life, economic development, and the planet’s ecological balance. However, as we move deeper into the 21st century, its availability and quality are increasingly at risk. Population growth, industrial and agricultural pollution, water scarcity in vulnerable...

In a world where climate change represents one of the greatest threats to our future, carbon dioxide (CO2) adsorption has become an urgent priority. The increasing concentration of CO2 in the atmosphere, primarily driven by human activities such as fossil fuel combustion and deforestation, has...

At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

Direct Air Capture (DAC) is an innovative technology that removes CO₂ directly from the air using chemical reactions with liquid solvents or solid absorbents. Despite challenges such as high costs and energy consumption, DAC offers a potential solution to reduce atmospheric CO₂ concentrations and...

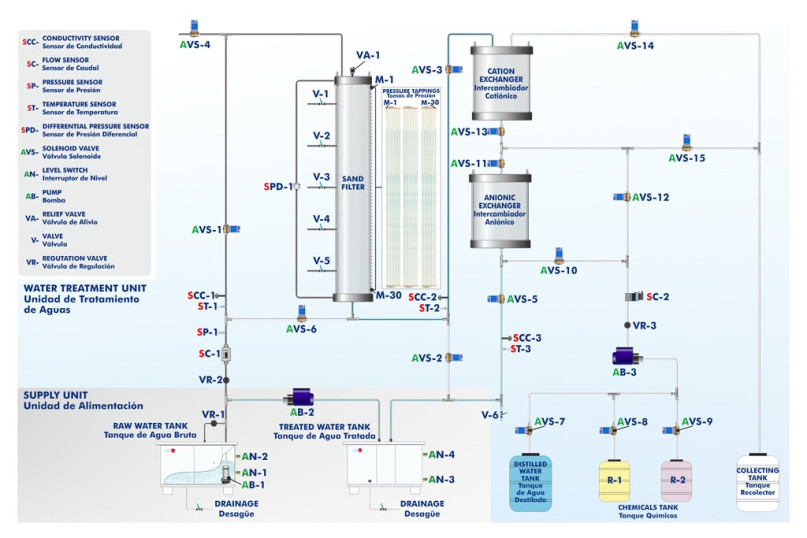

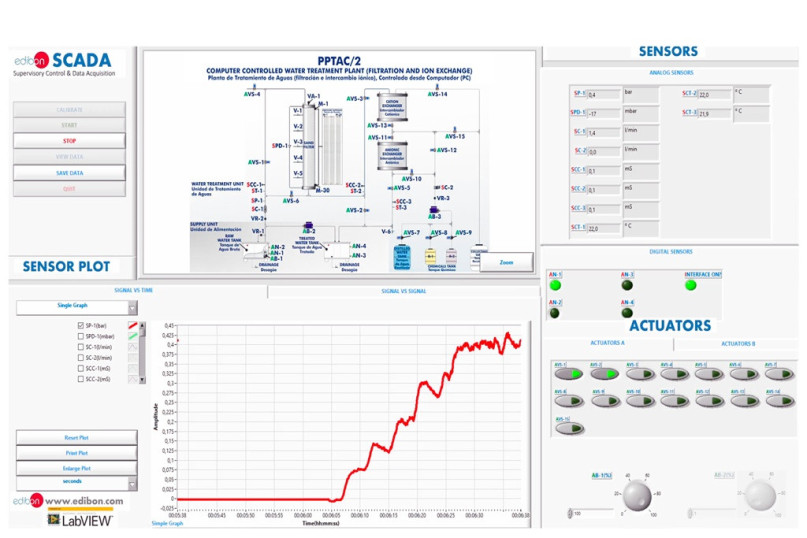

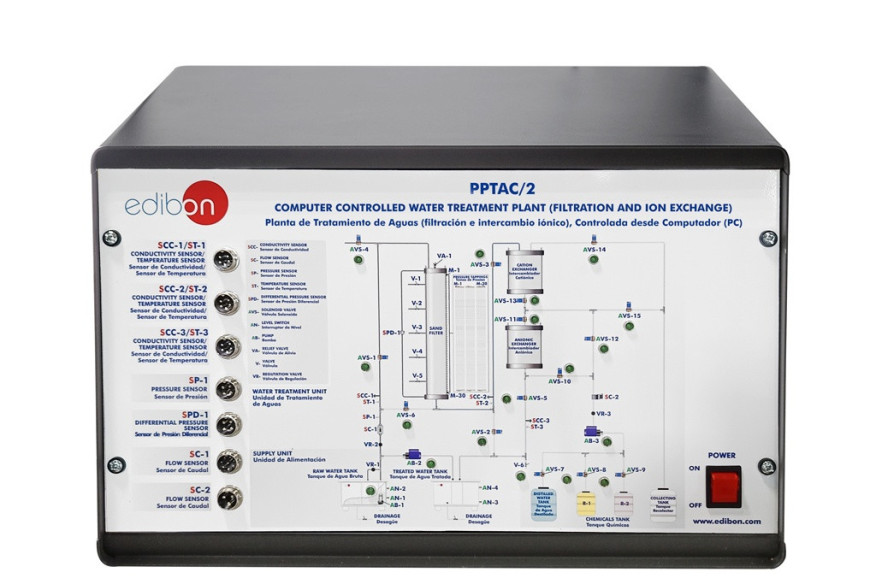

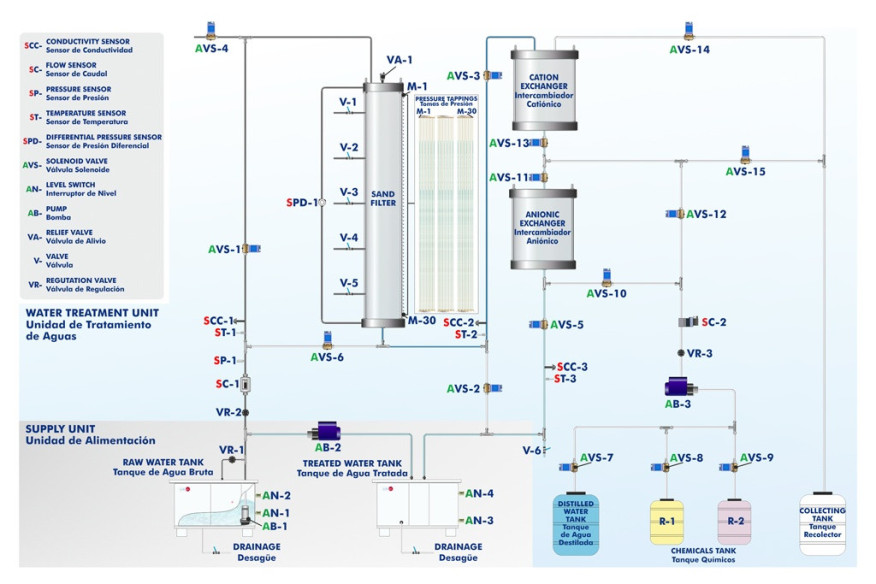

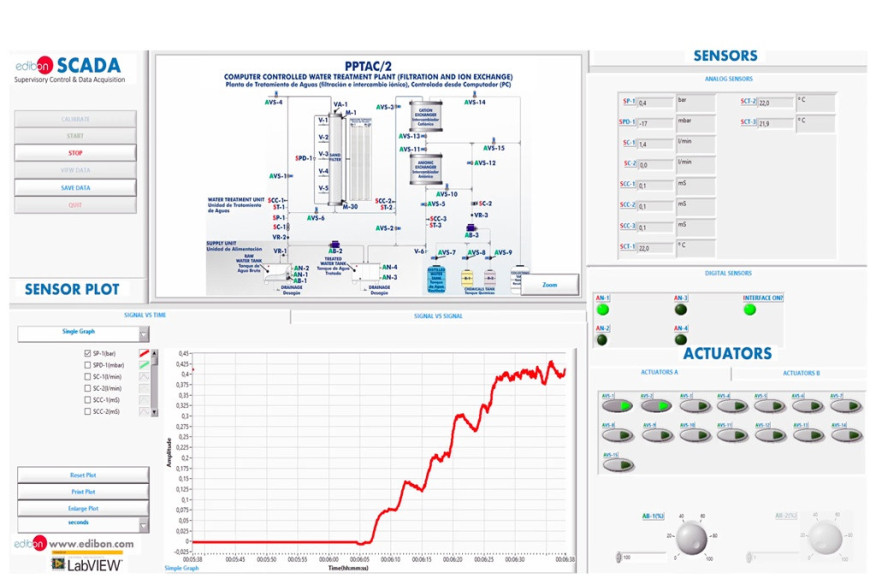

Ensuring access to safe drinking water involves complex processes and advanced technologies. Key components of a treatment plant include intake structures, coagulation, flocculation, sedimentation, filtration, disinfection, storage, and distribution. Modern systems use reverse osmosis, UV...

Food Technology is a branch of Food Science based on multidisciplinary knowledge of nutrition, chemical analysis, physics, biochemistry and engineering. Water treatment technologies obtain drinking water, so necessary for our life.

Both disciplines have become in recent years an indispensable...

Cookie preferences

Cookie preferences