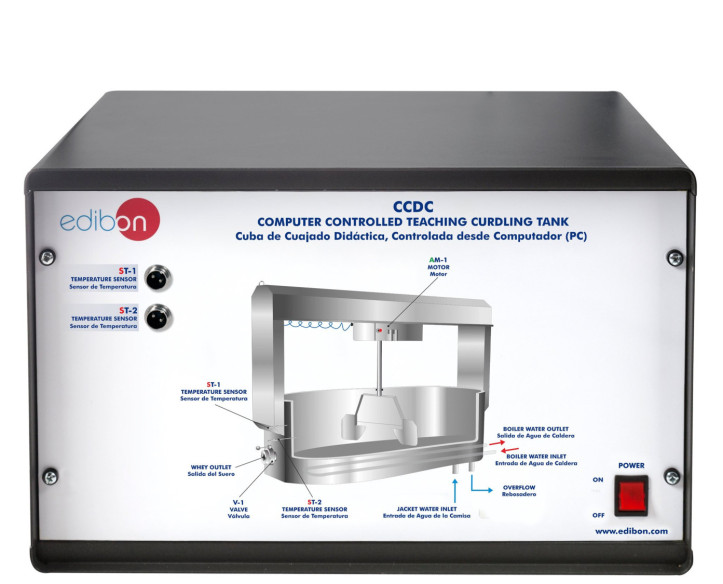

CCDC Computer Controlled Teaching Curdling Tank

INNOVATIVE SYSTEMS

The Computer Controlled Teaching Curdling Tank, "CCDC", designed by EDIBON, is employed to curdle milk in a tank with a water jacket and includes a set of accessories for the stirring, cutting and draining of the product.

Expansions

Laboratories

RELATED NEWS

General Description

The Computer Controlled Teaching Curdling Tank, "CCDC", designed by EDIBON, is employed to curdle milk, which is an essential process to make cheese.

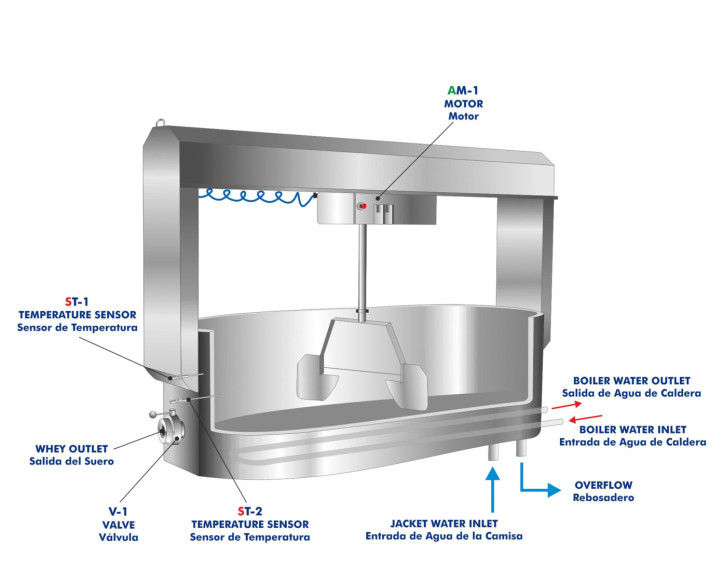

The unit has tank, water jacket, coil with one inlet and outlet for the water of the boiler, inlet for the water of the jacket, overflow, valve for the whey drainage and set of accessories for the stirring, cutting and draining of the product.

Pasteurized milk coming from a cooled milk tank is poured in the inner tank of the unit. Milk is heated to 30 – 32 °C with a water jacket with stainless steel coil, using water or steam in a closed circuit.

The unit includes a bridge with a shifter-gearmotor group that enables the displacement of the motor (computer controlled) along the unit in both directions. Thus, milk is stirred and the curd is automatically cut.

There are two temperature sensors to measure water and milk temperature. Water in the jacket is introduced through a filling/draining inlet. This inlet allows the draining of the water from the jacket as well. Air accumulated in the jacket and the excess water of the jacket is displaced through the overflow.

The whey outlet valve is employed to remove the excess whey after the curdling process.

Two transparent guards with safety interlocks protect students and allow the visibility of the practical exercises and components of the unit.

The unit includes set of accessories for the stirring, cutting and draining of the product. These accessories are: curd knives and stirrer and rising and prepressing plates attachable to the mechanized bridge.

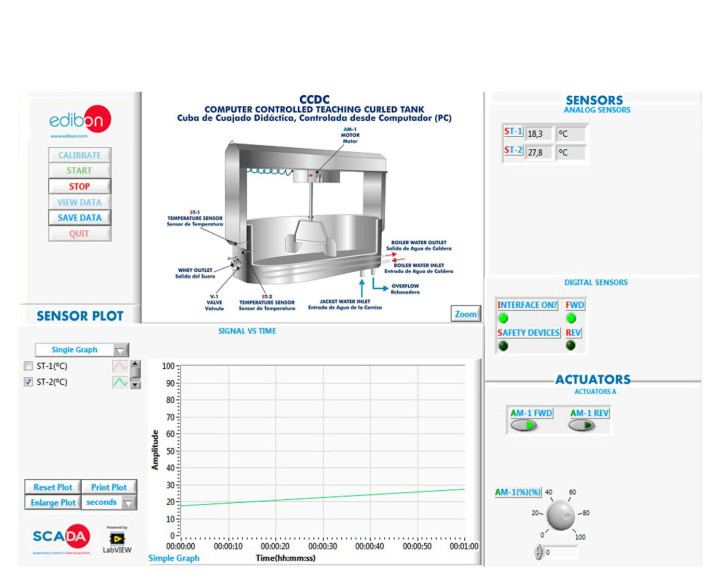

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Familiarization with the performance of a curdling tank.

- Study of the cultivation volume influence on the curdling process.

- Study of the rennet volume influence on the curdling process.

- Study of the influence of the curdling step duration on the curdling process.

- Study of the influence of velocity during the curdling step on the curdling process.

- Study of the influence of temperature during the curdling step on the curdling process.

- Study of the influence of the cutting step duration on the curdling process.

- Study of the influence of velocity during the cutting step on the curdling process.

- Study of the influence of temperature during the cutting step on the curdling process.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Sensors calibration.

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the CCDC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the CCDC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SIMILAR UNITS AVAILABLE

Dutch Vat for Cheese Production (until 50l)

SUPPLEMENTARY EQUIPMENT

Computer Controlled Teaching Cream Separator

Teaching Cream Separator

Computer Controlled Butter Maker Teaching Unit

Butter Maker Teaching Unit

Computer Controlled and Touch Screen UHT Unit

Computer Controlled Teaching Autonomous Pasteurization Unit

Computer Controlled Laboratory Pasteurizer

Computer Controlled Teaching Cheese Press

Dutch Vat for Cheese Production (until 50l)

Computer Controlled Teaching Yogurt Incubator

Computer Controlled Teaching Cottage Cheese Maker

Computer Controlled Cheese Vat

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences