EACC Computer Controlled Hot Water Production and Heating Teaching Unit

INNOVATIVE SYSTEMS

The computer controlled hot water and heating generation unit, "EACC", developed by EDIBON, is a didactic unit that the students can use to learn about heating installations and the production of domestic hot water, both for houses and colective blocks with a boiler in each dwelling.

Expansions

Laboratories

RELATED NEWS

General Description

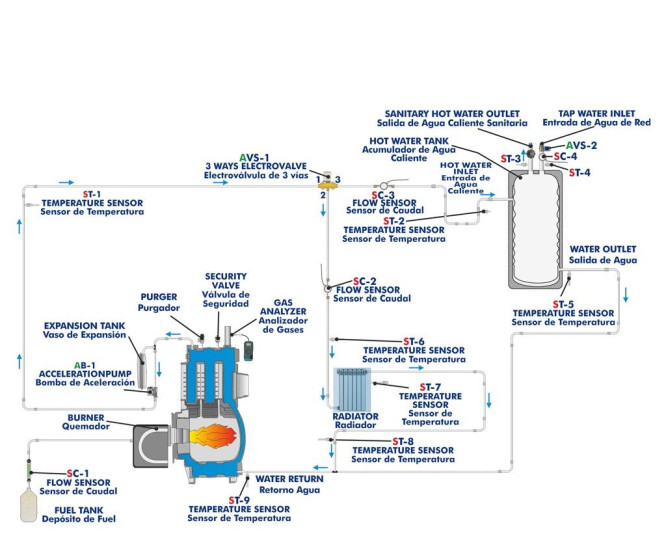

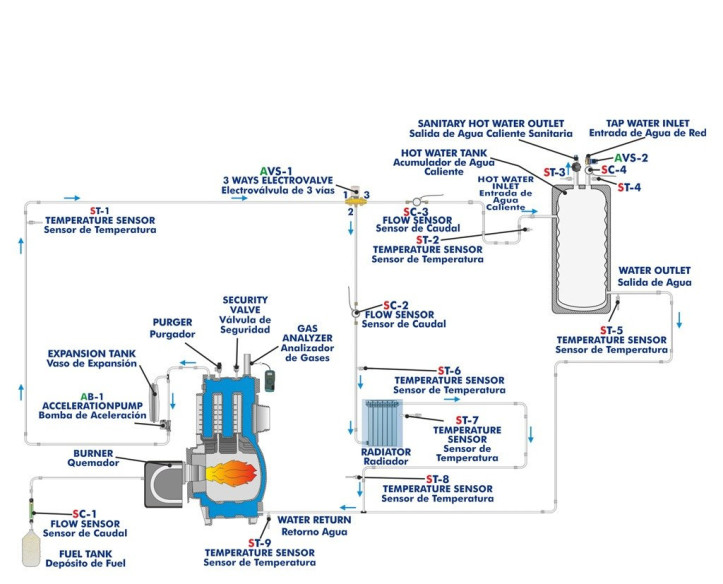

The main element of the Computer Controlled Hot Water Production and Heating Teaching Unit, "EACC", is the boiler. Its function is the heating of the water that will flow through the other elements transferring its heat. It is a low temperature boiler that works with gas-oil and it is suitable to work with pressurized burners for gas or gas-oil. The boiler includes an stage gas-oil burner, circulating pump, closed expansion tank, safety valve, air purger and drainage valve.

The burner has an On/Off operation. The mechanical atomization of gasoil at high pressure is made through a nozzle. Also, it allows to obtain combustion optimum values by means of the regulation of the combustive air (manually) and the deflector.

The unit includes an electronic three-ways valve, which distributes the water which has been previously heated by the boiler-burner group into two primary circuits. One of them is the double jacket of the hot water tank, to obtain domestic hot water, and the other is the radiator, to generate heating.

The hot water tank has a double jacket through which water previously heated in the boiler flows, constituting the primary circuit. There is a solenoid valve in the line that introduces tap water to the hot water tank to be heated. It will be opened or closed depending on the needs.

The part of the unit where the heating generation is studied is constituted by a fin radiator of five elements and a purger, which is inside a metacrylate receptacle, allowing to control the time spent on heating the receptacle until reaching the target temperature or the fuel flow required for that purpose.

It is possible to control the temperature in such receptacle by means of a PID control through the software that acts on the three-ways solenoid valve. The receptacle has a room thermostat inside, which makes it possible to control the heating temperature.

The primary circuit is closed with the recirculation of both the circuit’s water, that has already transferred its heat in the hot water tank, and the water from the radiator. Both lines converge and are connected to the boiler again, thus closing the primary circuit.

The unit includes a suitable chimney for the boiler for a correct installation of the unit.

There is a portable gas analyzer to analyze the combustion fumes that go out from the boiler. Measurements of CO, CO2, O2, combustion efficiency, excess of air and temperature of the combustion gases can be obtained with this device.

The sensors and instrumentation supplied with the unit makes it possible to know at any moment the measurement of:

- Flows: the fuel flow consumed by the boiler depending on the needs, the water flow used for the primary circuit of the hot water tank, the water flow used for the primary circuit of the radiator to generate heating and the tap water inlet flow into the hot water tank.

- Temperatures: the temperature of the hot water leaving the boiler, the temperature of the water outlet and inlet of the primary circuit of the hot water tank and the radiator, the temperature of the domestic hot water inside the hot water tank and the domestic hot water outlet and the temperature of the primary circuit´s water that recirculates to the boiler.

- Measurement of CO, CO2, O2, combustion efficiency, air excess and temperature of combustion fumes.

- Signals of the burner´s operation process: ignition spark, ventilation, emergency stop alarm signal (safety thermostat), electrovalve, etc.

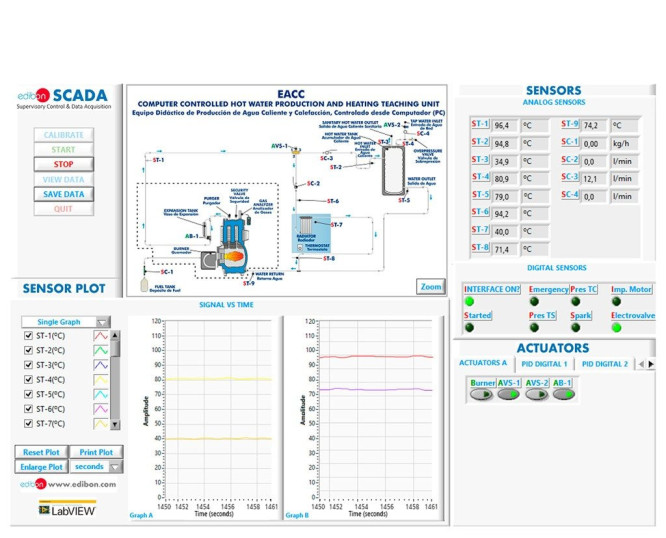

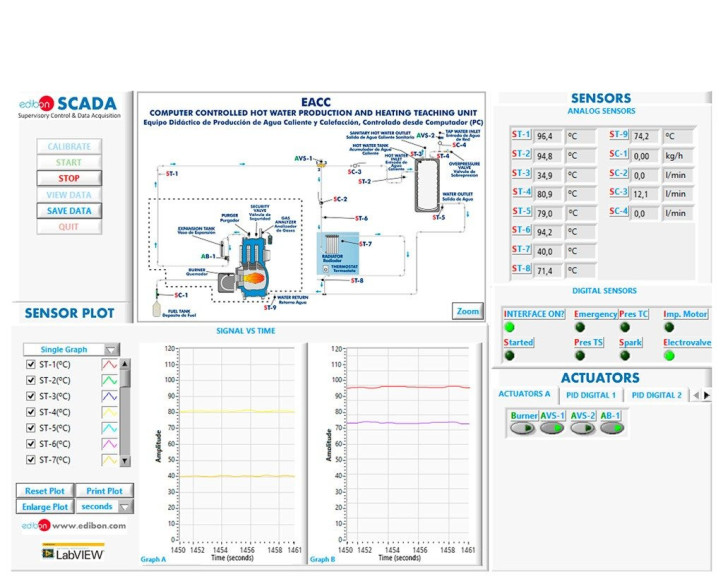

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Familiarization with the operation of a heating and domestic hot water (DHW) installation.

- Determination of the fuel flow and fuel consumption.

- Determination of the boiler’s temperature.

- Determination of the heating water inlet and outlet temperature.

- Determination of the domestic hot water (DHW) temperature.

- Energy balance of the heating circuit.

- Energy balance of the domestic hot water (DHW) circuit.

- Calculation of the energy efficiency.

- Variation of the exhaust gases outlet in function of the combustion quality.

- Influence of the target heating of the domestic hot water (DHW) temperature on the constituents of the combustion fumes and on the combustion efficiency.

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EACC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EACC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SUPPLEMENTARY EQUIPMENT

Biomass Process Unit

Computer Controlled Unit to Study the Efficiency of a Heating System

Water Heaters Training Unit

Heat Pump for different Heat Sources and Heat Exchangers

Underfloor Heating and/or Heat Source for Heat Pump

Fan Heater and/or Air Heat Exchanger

Computer Controlled Air Conditioning Laboratory Unit

Air Conditioning Laboratory Unit

Computer Controlled Recirculating Air Conditioning Unit

Recirculating Air Conditioning Unit

Computer Controlled Automobile Air Conditioning Unit

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences