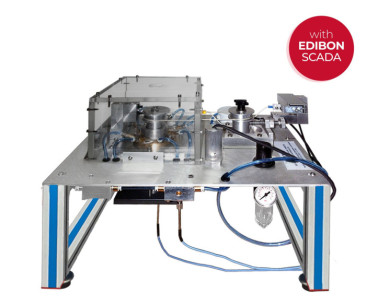

TFC Computer Controlled Francis Turbine

INNOVATIVE SYSTEMS

The Computer Controlled Francis Turbine "TFC", designed by EDIBON, consists is a small scale Francis turbine (action turbine). The Francis Turbine is the most common type of turbine installed in power generation plants that operate on the basis of mass flow of water through a production plant.

Expansions

Laboratories

RELATED NEWS

General Description

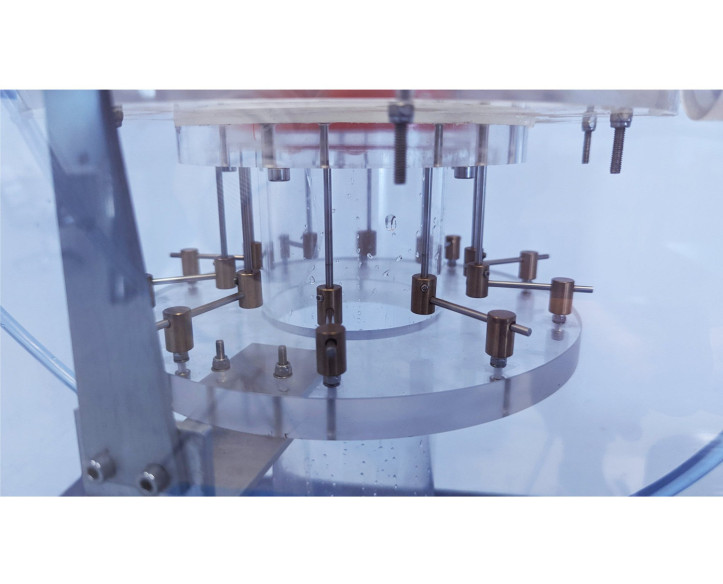

The Computer Controlled Francis Turbine, "TFC", designed by EDIBON, consists of a small-scale Francis turbine, with a valve that allows flow regulation and has a ring with adjustable guide vanes that allows control of the angle of incidence of the water in the turbine.

The feed chamber is spiral-shaped and is therefore known as a snail chamber. Due to its design, the water circulates with apparently constant speed and without forming whirls, thus avoiding pressure losses.

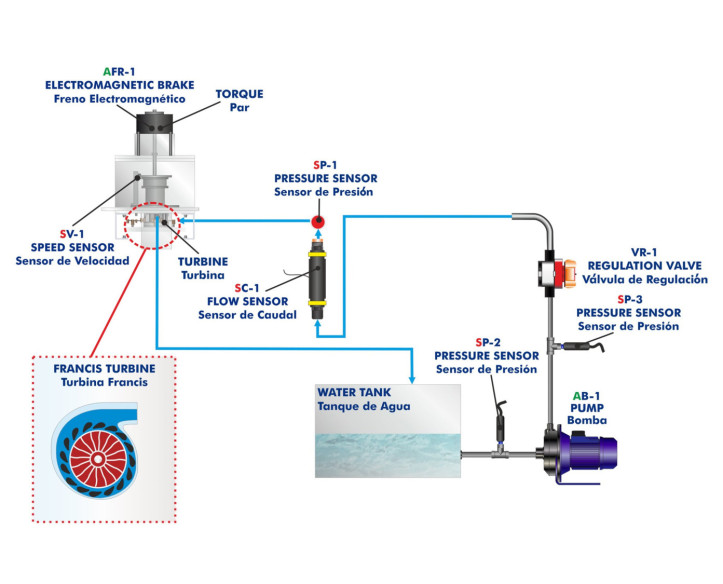

In order to raise the fluid, it has a computer controlled pump that enables the impelled flow to pass through the turbine, in which part of its energy is left, causing the turbine to turn, overcoming the external resistance caused by an electromagnetic brake. This computer controlled brake makes it possible to vary the braking load on the turbine.

In addition, the unit is equipped with a pressure sensor placed at the turbine water inlet which.

measures the inlet pressure, a flow sensor to measure the turbine water inlet flow, an optical sensor which determines the speed of the turbine shaft, and has two pressure sensors at the pump inlet and outlet, in order to obtain its characteristic curve.

The pump-turbine group has a tank and a pipes system which allow to work constantly with recirculated fluid to avoid the indiscriminate water consumption.

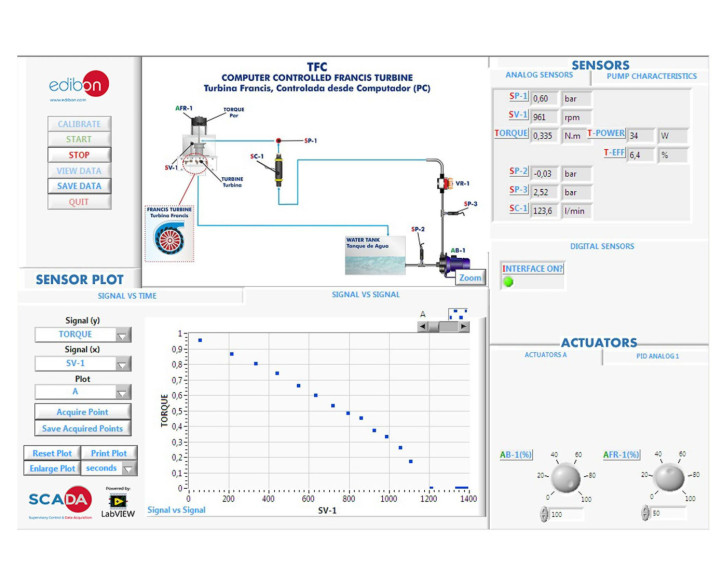

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- To determine the operating characteristics of a Francis turbine at different speeds.

- Investigation of the conversion of hydraulic energy into mechanical energy.

- Determination of the characteristic curves of a turbine: power (W), torque (Nm) and efficiency (%) as a function of the turbine speed and the inlet flow rate.

- Determination of the characteristic curve of a hydraulic pump.

- Determination of the height of a hydraulic turbine.

- Effect of guide vanes setting on the turbine performance.

- Adimensional analysis.

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TFC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TFC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SIMILAR UNITS AVAILABLE

Computer Controlled Hydraulic Turbines Modular Unit

SUPPLEMENTARY EQUIPMENT

Computer Controlled Hydroelectric Power Plant with Pelton Turbine

Computer Controlled Hydroelectric Power Plant with Francis Turbine

Pumping Storage Power Plant Application, with SCADA

Computer Controlled Pelton Turbine

Computer Controlled Kaplan Turbine

Computer Controlled Radial Flow Turbine

Computer Controlled Axial Flow Turbine

Computer Controlled Experimental Reaction Turbine

Computer Controlled Experimental Impulse Turbine

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences