Are you a teacher or do you work as an engineering researcher? EDIBON offers courses for teachers and #research staff. Take a look at the course of Fluid Mechanics and learn about #fluids properties. #DiscoverEdibon #Engineering.

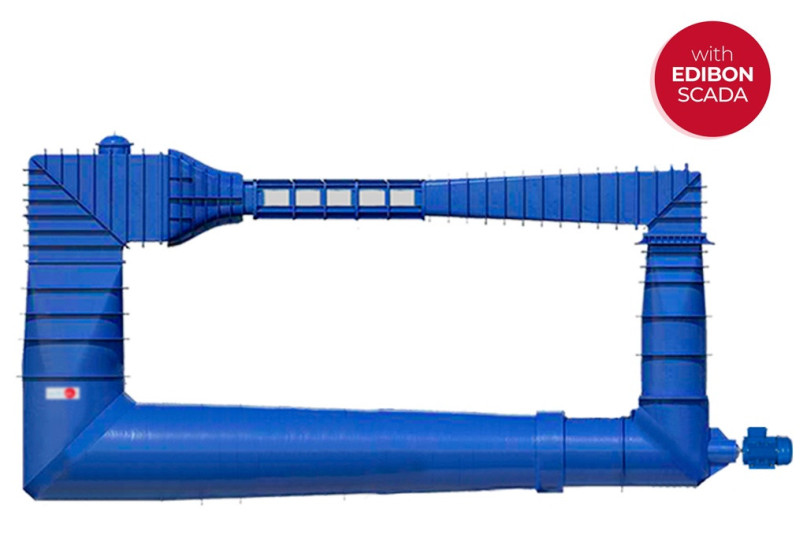

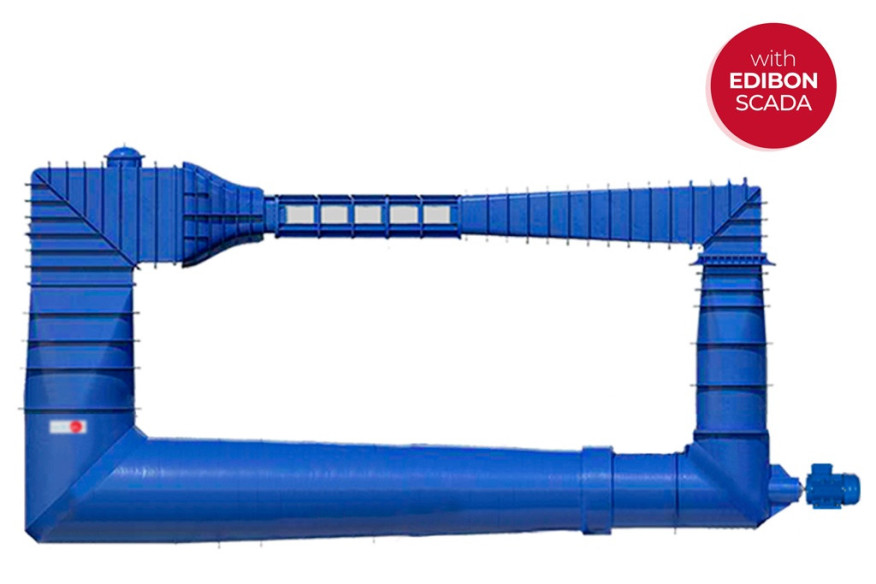

HTHS150/150C Computer Controlled Closed Hydrodynamic Tunnel for Hight Speed, 150X150 mm

INNOVATIVE SYSTEMS

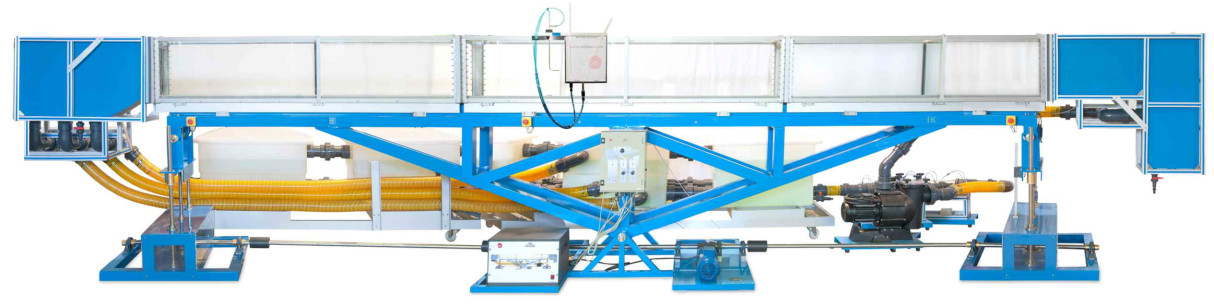

The Computer Controlled Closed Hydrodynamic Tunnel for High Speed, 150 x 150 mm, "HTHS150/150C", allows the study of complete hydrodynamics. In addition, being sealed and being able to reduce or increase its internal static pressure, it allows cavitation studies to be carried out.

RELATED NEWS

General Description

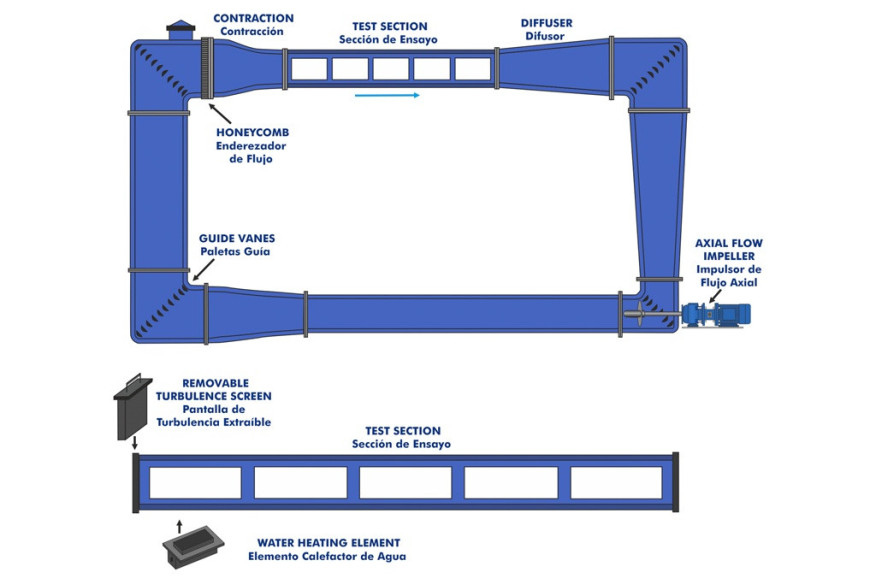

The Computer Controlled Closed Hydrodynamic Tunnel for High Speed, 150 x 150 mm, "HTHS150/150C", is a closed circuit cavitation tunnel with water flowing in the vertical plane. The water is circulated by a computer controlled variable speed axial propeller pump located at the bottom of the tunnel.

The unit includes several tunnel sections to reduce flow interference. A contraction upstream of the working area with a perfectly studied contraction curve contour ensures a well-developed water flow in the working area.

A honeycomb flow stabilizer is located in the section upstream of the shrinkage for greater flow uniformity in the working area.

The working area is located downstream of the shrinkage. It consists of a constant section section, where the models for testing are mounted. It is made with fused silica (quartz) windows on the front, back and top face for optical testing. This section includes a Pitot tube in its upper part to study static pressure, dynamic pressure and total pressure. It also includes a removable screen at the inlet to increase the turbulence of the flow.

A diffuser is included at the tunnel outlet to avoid the generation of turbulence that can damage the quality of the flow in the working area.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Extensive study of hydrodynamics and water flow studies.

- Study of flow visualization.

- Study of static pressure, dynamic pressure and total pressure using a Pitot tube.

- Study of the measurement of velocity using a Pitot tube.

- Study of turbulent and laminar flow.

- Calibration of sensors.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

Additional practical possibilities to be carried out with the recommended additional elements (Not included):

- Study of cavitation in different models.

- Thrust and torque measurement.

- Study of cavitation as a function of the number of propeller blades.

- Study of the noise production inherent to cavitation.

- Study of the pressure fluctuations due to cavitation.

- Performance losses due to cavitation.

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the HTHS150/150C unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the HTHS150/150C unit process.

- Several other exercises can be done and designed by the user.

SUPPLEMENTARY EQUIPMENT

8.5.- HYDRAULIC CHANNELS

CFC

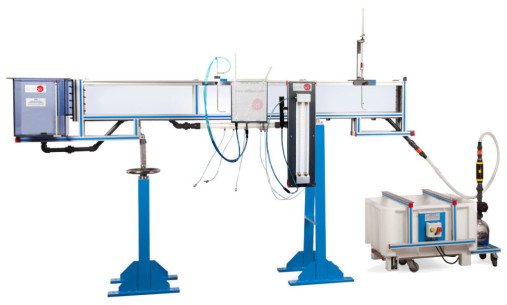

Channel, through which water flows, of rectangular section with transparent walls that enable to observe all the experiments. Water is taken from the storage tank by means of a hydraulic pump, with speed regulation, and, by the pipe, it is driven...

8.5.- HYDRAULIC CHANNELS

CF

Flow Channels (section: 80X300 mm)

Channel, through which water flows, of rectangular section with transparent walls that enable to observe all the experiments. Water is taken from the storage tank by means of a hydraulic pump and, by the pipe, it is driven to the inlet tank, where...

8.5.- HYDRAULIC CHANNELS

CFGC

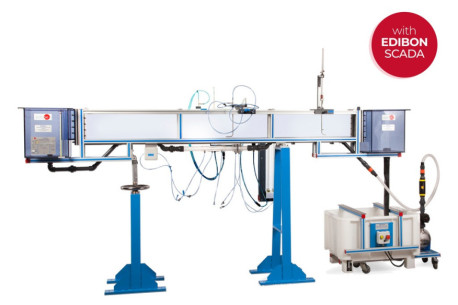

Computer Controlled Flow Channels

The Computer Controlled Flow Channels, "CFGC", are hydrodynamic channels to perform multiple hydraulic tests. They consist of a rectangular section channel with tempered glass transparent walls through which water flows. Water is impelled by a...

8.5.- HYDRAULIC CHANNELS

CFG

Flow Channels

The Flow Channels, "CFG", are hydrodynamic channels to perform multiple hydraulic tests. They consist of a rectangular section channel with tempered glass transparent walls through which water flows. Water is impelled by a pump from the storage...

8.5.- HYDRAULIC CHANNELS

HTLS150/150C

Computer Controlled Closed Hydrodynamic Tunnel for Low Speed, 150X150 mm

The Computer Controlled Low Speed Hydrodynamic Tunnel, 150 x 150 mm, "HTLS150/150C", is a hydrodynamic tunnel in a closed water circuit flowing in the vertical plane. The water is circulated by a computer controlled variable speed pump. Different...

13.1.- HYDROLOGY AND HYDROGEOLOGY

CAS

Sediment Transport Demonstration Channel

The Sediment Transport Demonstration Channel, "CAS", designed by EDIBON, consist of an inclinable channel mounted on a base plate, supported by two supports, with a discharge tank and recirculating pump. This tank is in the Basic Hydraulic Feed...

13.1.- HYDROLOGY AND HYDROGEOLOGY

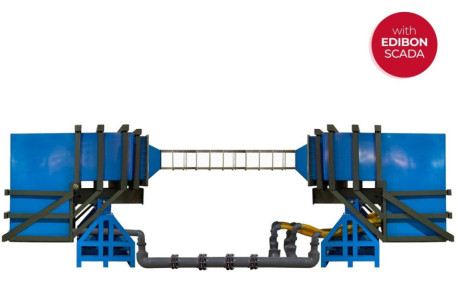

HVFLM-2

Mobile Bed and Flow Visualization Unit (working section: 2000X610 mm)

The Mobile Bed and Flow Visualization Unit (working section: 2000x610 mm), "HVFLM-2", may be used mainly in two study fields. The first one is the investigation of mobile beds, which are related to water courses and civil engineering structures....

13.1.- HYDROLOGY AND HYDROGEOLOGY

HVFLM-4

Mobile Bed and Flow Visualization Unit (working section: 4000x610 mm)

The Mobile Bed and Flow Visualization Unit (working section: 4000 x 610 mm), "HVFLM-4", may be used mainly in two study fields. The first one is the investigation of mobile beds, which are related to water courses and civil engineering structures....

8.4.- FLOW VISUALIZATION

WFPC

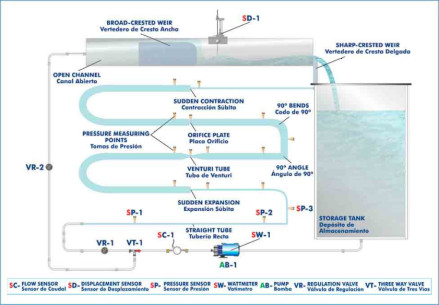

Computer Controlled Unit to Study Water Flow Principles

The Computer Controlled Unit to Study Water Flow Principles, "WFPC", is composed by both a closed and an open water circuit, thus allowing the observation of fluid's behavior in each of them. The selection of the circuit can be made by means of a...

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences