SSPC コンピューター制御スプレー式乾燥機

革新的なシステム

The Computer Controlled Spray Drier, "SSPC", designed by EDIBON, allows to study processes that involve aqueous emulsions, solutions, suspensions and colloidal solutions.

拡張

研究室

関連ニュース

概要

The Computer Controlled Spray Drier, "SSPC", designed by EDIBON, allows to study processes that involve aqueous emulsions, solutions, suspensions and colloidal solutions.

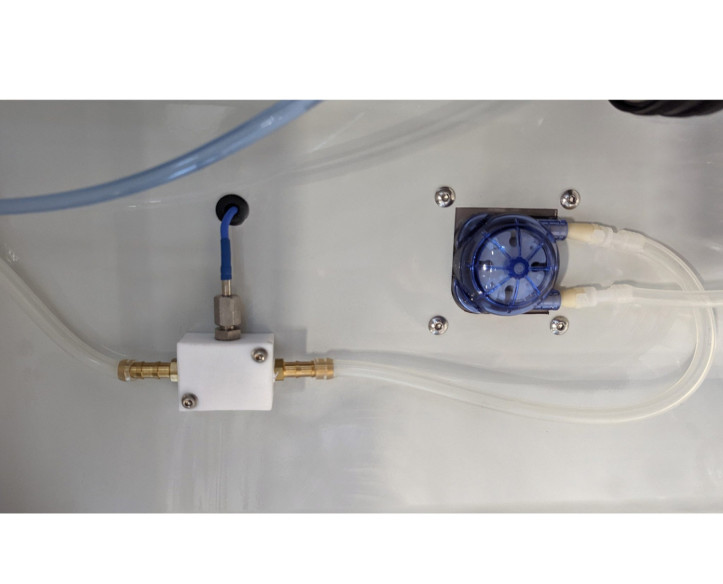

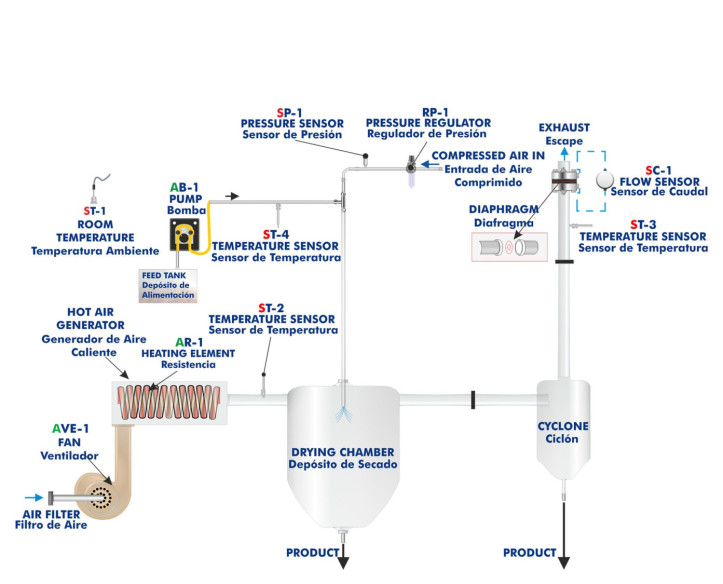

Peristaltic pump delivers the liquid sample from a container through a small diameter jet into the drying chamber. At the same time compressed air enters the outer tube of the jet which causes the liquid to emerge as a fine atomized spray into the drying chamber. Heated air is blown through the drying chamber evaporating the liquid content of the atomized spray.

The solid particles of the material are separated from the exhaust air flow by a cyclone and collected in the sample collection bottle. The exhaust airflow is directed to the atmosphere or to an extraction system existing in the laboratory.

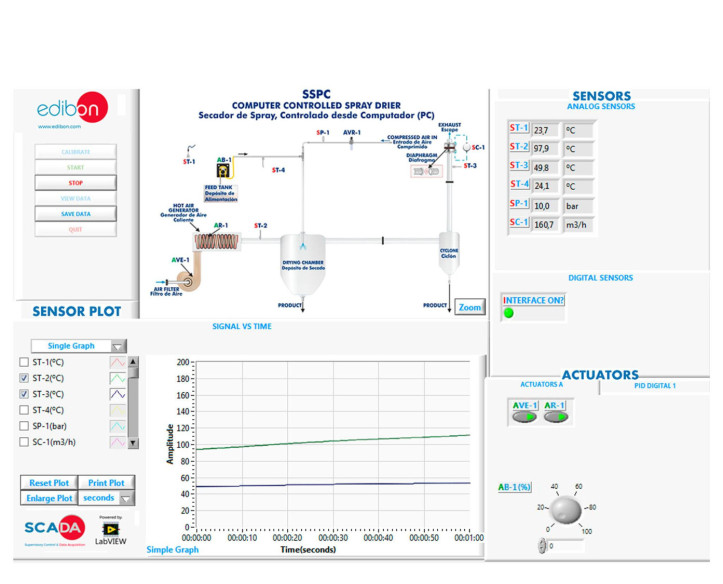

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Operation principle of a spray drier.

- Effect of the drop size on the drying process.

- Mass balance of a spray drier.

- Effect of the air input temperature on the drying process.

- Sensors calibration.

より実用的な練習をして、ユニットを完成させる

- Effect of the feed flow of the product on the drying process.

- Spray drier efficiency.

- Energy balance of a spray drier.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the SSPC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the SSPC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

利用可能な類似の機器

補完的な機器

コンピューター制御ベンチトップ冷却塔

ベンチトップ冷却塔

コンピューター制御トレイ式乾燥機

スプレー式乾燥機

コンピューター制御のスプレードライおよび冷却装置

フリーズドライヤー

品質

アフターサービス

クッキーの設定

クッキーの設定