At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

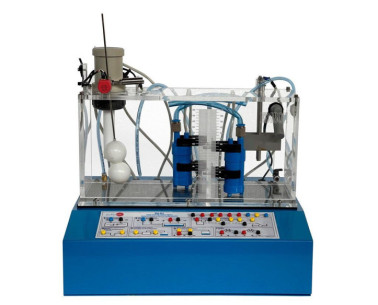

BS9-PLC Pneumatic Test Module for PLC

INNOVATIVE SYSTEMS

The "BS9-PLC" has been designed to study the control and handling techniques of a pneumatic actuator through a PLC.

RELATED NEWS

General Description

The "BS9-PLC" has been designed to study the control and handling techniques of a pneumatic actuator through a PLC. The actuator is a double acting pneumatic cylinder that allows moving a platform. The displacement of the piston axle is detected by a linear displacement sensor LVDT. The position of the pneumatic cylinder is controlled by two proportional electronic valves. The pressure difference between the piston inlets is measured by a differential pressure sensor and the supply of compressed air is provided by a compressor. The pneumatic cylinder position is controlled by PLC depending on the obtained signals from the position sensor.

* Available PLC models of different manufacturers: PANASONIC, SIEMENS, OMRON, MITSUBISHI, ALLEN BRADLEY, etc.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Proportional valves. To control electronically the vertical displacement of a double effect pneumatic piston using proportional valves.

- Differential pressure sensor. To use a pressure sensor for measuring the pressure difference between both pneumatic piston air inlets.

- Pneumatic switch. To deflect the air flow using a pneumatic switch.

- LVDT Linear Displacement Sensor. To measure pneumatic piston displacement using an excitation and DC output LVDT.

- Using the analogs input and outputs of the PLC to read and write analog signals.

- Read the position sensor signal with the PLC.

- Manual control of the actuator through the PLC.

- PID control of the cylinder position through the PLC.

- Observe the effects of the position control to changes in the PID parameters.

SUPPLEMENTARY EQUIPMENT

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS-PLC

The Modular System for the Study of Sensors with PLC Control, "PLC-BS", are a large number of modules that show the operation of different sensors to understand the sensor control applications of different technologies, applied to common...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS2-PLC

Temperature Test Module for PLC

The "BS2-PLC" has been designed to study the use and applications of temperature sensors as a measure device and how to perform a temperature control through a PLC. TThe unit has a half-open space inside which there is a lamp that heats the...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS3-PLC

Pressure Test Module for PLC

The "BS3-PLC" has been designed to study the pressure measurement techniques and control application with a PLC. This unit is equipped with a pressure chamber with several sensors, with different uses and applications, adjusted to measure the...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS4-PLC

Flow Test Module for PLC

The "BS4-PLC" has been designed to study the flow measurement techniques and control with PLC. This unit is unit with two tanks assembled on a structure with a pumping system that allows pumping the water from the reservoir tank, through the...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS5-PLC

Ovens Test Module for PLC

The "BS5-PLC" has been designed to study the temperature measurement techniques inside a sealed place, such as an oven and how to perform a temperature control through a PLC. This unit is equipped with an oven that contains a heating element and a...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS6-PLC

Liquid Level Test Module for PLC

The "BS6-PLC" has been designed to study the liquid level measurement and control techniques of a tank through a PLC. This unit is unit with two tanks with sensor of different technology for level measurement. One of the level sensor output...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS7-PLC

Tachometers Test Module for PLC

The "BS7-PLC" has been designed to study the linear and angular speed measurement techniques through a PLC. This unit is unit with a miniature motor to move an axle at different speeds, being able to adjust de motor speed by changing the voltage...

6.2.3.- INSTRUMENTATION AND CONTROL WITH PLC

BS10-PLC

Light Test Module for PLC

The "BS10-PLC" has been designed to study different light measurement techniques and control light intensity through a PLC. This unit is composed of a lamp whose intensity can be controlled according to the voltage applied and a series of...

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences