FOR FURTHER INFORMATION, CONTACT US

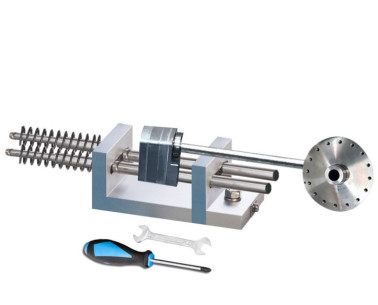

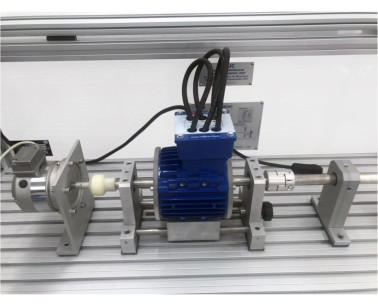

7.4.- INSTALLATIONS AND MAINTENANCE

The needs of today's society are a challenge for any industry, since they have to be in continuous evolution and renewal to adapt to those needs.

View moreIn recent years, as a result of the new industrial revolution or "Industry 4.0", the emergence of the "Industrial Internet of Things" ("IIoT") and the "Smart Factories", that adaptation is possible thanks to the application of the most sophisticated techniques in the design of new facilities or in the renovation of existing ones.

In spite of all these technological advances and the exhaustive controls carried out, it should not be forgotten that any element that take part in the productive process is going to be subjected to a mechanical and electrical wear (efforts, loads, etc.) and its useful life is limited. To avoid catastrophic failures, stoppages in production or any type of process that implies an increase of non-productive times and, therefore, an increase of costs, it is extremely important to carry out a good maintenance of machinery, electrical systems, etc.

Traditionally, only two types of maintenance were considered:

- Corrective: the fault is solved once it has already occurred.

- Preventive: periodic review of all those problematic elements and their replacement if required.

These types of maintenance involve very high and unnecessary costs in most cases. Nowadays, thanks to the available technology, it is possible to carry out predictive maintenance consisting of a comprehensive analysis of all those variables that take part in all the components of a system and be able to replace them at the right time.

But, if more control over the failures that can suffer all those mechanical components subject to wear is preferred, there is another type of maintenance, known as proactive maintenance. It goes one step further than the predictive maintenance, looking for the root of the problem.

View Products Cookie preferences

Cookie preferences