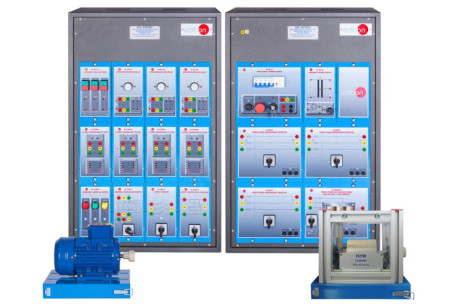

The Electrical Machines Soft Starters Application, "AEL-EMSS", has been designed by EDIBON to instruct the student in managing soft-starters of three-phase electrical machines. This application basically consists of three types of optional starters: electronic soft starter (Electronic Soft Starter Module (N-ARR16)), frequency controller (Advanced AC Motors Speed Controller (N-VVCA)) and star/delta starter Three-Phase Autotransformer 400/230 VAC, 1 kVA, Module (N-TRANS03) y Manual Star-Delta Starter (N-ARR01). The students will learn to configure these type of starters and they will compare the characteristics and functionality observing the induction motor behavior with each starter.

Description of the soft starter types:

- N-ARR16. Electronic Soft Starter Module: through the electronic soft starter, the user will learn to configure the most important parameters that allow considerably reduce the induction motor starting/stopping currents. These parameters are, for example, the staring voltage, the acceleration ramp time and the deceleration ramp time.

- N-VVCA. Advanced AC Motors Speed Controller: through the advanced frequency controller, the user will learn to configure several parameters to get different induction motor functionalities. Thus different parameters can be set such as torque limiter, frequency limiter, acceleration and deceleration ramps, starting voltage and much more parameters explained in the user´s manual. It is very important to understand how a motor works with a frequency controller because it is the most important method used in the industry for induction motor control to get a maximum control and performance. Besides, the user can visualize, program the alarms and associate them to relays in order to get a complex control circuit. The frequency controller module has some digital signals which can be programed to get more than 100 different functions.

- N-TRANS03. Three-Phase Autotransformer 400/230 VAC, 1 kVA, Module and N-ARR01. Manual Star-Delta Starter: through the manual star/delta starter, the user will take experience on this type of maneuvers and how the response of the induction motor is.

This application includes an eddy current brake to study the induction motor response to different load conditions.

On the other hand, for more advanced studies of induction motor dynamics, it is recommended to acquire the "N-SERV1K" servomotor, which includes a controller to perform different braking tests with greater precision. This controller can work together with the "EM-SCADA" module.

When the braking torque is increased, the power consumption of the induction motor is increased too, the power factor changes, etc. In order to analyze the power consumption of the induction motor a network analyzer is included. It shows the main electrical parameters which are relevant in industrial installations: voltages, currents, frequencies, Power Factor, active power, reactive power, apparent power, etc.

This aplication can be supplied with theControl and Data Acquisition System Software for Electrical Machines, "EM-SCADA", a Data Control and Acquisition Software developed by EDIBON that allows monitoring all voltage, current and torque waves shape. This allows studying the behavior of the three-phase induction motor via different soft starters offered in this application. The servomotor can be controlled from the PC with EM-SCADA to generate different load curves on the induction motor shaft. In this way it is possible to graphically obtain the characteristic curves of this type of motor.

Cookie preferences

Cookie preferences