QRC Computer Controlled Chemical Reactors

INNOVATIVE SYSTEMS

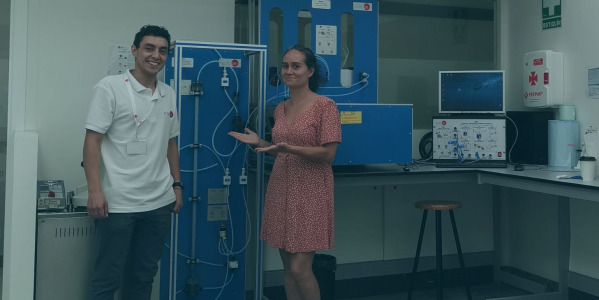

The Computer Controlled Chemical Reactors, "QRC", has been designed by EDIBON for the study and comparison of different types of chemical reactors in an easy and simple way and thus allowing, on a small scale, to carry out the necessary studies and practices to understand the operation of the reactors.

Laboratories

RELATED NEWS

General Description

The Computer Controlled Chemical Reactors, "QRC", has been designed by EDIBON for the study and comparison of different types of chemical reactors in an easy and simple way and thus allowing, on a small scale, to carry out the necessary studies and practices to understand the operation of the reactors.

These reactors allow for the comparison of different types of chemical reactors, and with each type of reactor, the study of the influence of reaction temperature and residence time is enabled, thanks to the thermostatic bath, two 1 l tanks, and two regulation pumps of up to 3 l/min included in the supply.

The Service Unit for QRC, "QUSC", provides the necessary elements for the operation of the different reactor modules. It performs the following functions:

- Reagent supply: consisting of two 1 l pyrex containers each located at the back, two dosing pumps and all the necessary connections.

- Temperature control: consisting of a thermostatic bath and an impulsion pump.

- Quick and easy to perform reactor exchange and positioning system.

- This unit allows feeding reagents and temperature control of reactors with a volume up to 1.5 l.

These Computer Controlled Units are supplied with EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Accessories

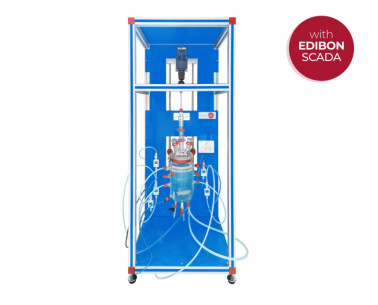

Computer Controlled Continuous Stirred Tank Reactor for QRC

Computer Controlled Tubular Flow Reactor for QRC

Computer Controlled Batch Reactor for QRC

Computer Controlled Stirred Tank Reactors in Series for QRC

Computer Controlled Laminar Flow Reactor for QRC

Computer Controlled Plug Flow Reactor for QRC

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

Practices to be done with the Continuous Stirred Tank Reactor for QR (QRCA):

- Calibration of the reagents flows.

- Determination of the ionic conductivities.

- Batch operation. Obtaining of the reaction order respect to ethylacetate. Initial velocity method.

- Batch operation. Obtaining of the reaction order respect to sodium hydroxide. Initial velocity method.

- Batch operation. Velocity Constant Computation. Constant sodium hydroxide initial concentration.

- Batch operation. Velocity Constant Computation. Constant ethylacetate initial concentration.

- Batch operation. Velocity Constant Computation. Constant sodium hydroxide initial concentration.

- Batch operation. Variation of the kinetic constant with temperature. Arrhenius Equation.

- Batch operation. Theoretical and experimental conversion comparative. Deviation from ideality.

- Batch operation. Demonstration of the influence of stirring on the experimental conversion in the ethyl acetate hydrolysis reaction.

- Study the difference between batch and continuous operation.

- Sensors calibration.

Additional practical possibilities:

- Batch operation. Mixture effects.

- Continuous operation. Mixture effects.

- Conductivity measurement system: conductimeter.

- Variation of conversion with residence time.

- Residence time distribution.

- Determination of the reaction rate constant.

Practices to be done with the Tubular Flow Reactor for QR (QRT):

- Determination of the ionic conductivities.

- Theoretical conversion of the tubular reactor.

- Experimental determination of the tubular reactor conversion.

- Dependence on the residence time.

- Determination of the reaction order.

- Dependence of the rate constant and the conversion on the temperature.

- Sensors calibration.

Additional practical possibilities:

- Analysis of reagents and products.

- Conductivity measurement system: conductimeter.

- Complete emptying of the unit.

- Determination of the reaction rate constant.

Practices to be done with the Batch Reactor for QR (QRD):

- Determination of the ionic conductivities.

- Batch operation. Calculation of the order of the reaction referred to the ethyl-acetate. Initial velocity method.

- Batch operation. Determination of the order of the reaction referred to the sodium hydroxide. Initial velocity method.

- Batch operation. Determination of the speed constant, the initial concentration of the sodium hydroxide is constant.

- Batch operation. Determination of the speed constant, the initial concentration of the ethyl acetate is constant.

- Formulation of the speed equation.

- Batch operation. Variation of the kinetic constant when the temperature is not constant: Arrhenius equation.

- Batch operation. Comparison of the theoretical and the experimental conversion: Deviation from the ideality.

- Batch operation. Mixture effects.

- Calculation of the heat transference coefficient of the coil.

- Calculation of the hydrolysis reaction enthalpy.

- Sensors calibration.

Additional practical possibilities:

- Conductivity measurement system: conductimeter.

Practices to be done with the Stirred Tank Reactors in Series for QR (QRS):

- Calibration of the peristaltic pumps of the reagents to obtain the reagents flow measurements.

- Determination of the ionic conductivities.

- Discontinuous operation. Obtention of the reaction order with respect to ethyl acetate. Initial velocity method.

- Discontinuous operation. Obtention of the reaction order with respect to sodium hydroxide. Initial velocity method.

- Batch operation. Velocity constant calculation. Constant sodium hydroxide initial concentration.

- Batch Operation. Velocity constant calculation. Constant ethylacetate initial concentration.

- Velocity equation formulation.

- Batch operation. Variation of the kinetic constant with temperature. Arrhenius equation.

- Batch operation. Comparison between theoretical and experimental conversion. Deviation from ideality.

- DemonstratIon the influence of stirring on the experimental conversion in the ethyl acetate hydrolysis reaction.

- Study the difference between batch and continuos operation modes.

- Study of basic hydrolysis of the ethyl acetate with the three reactors in a continuous operation configuration.

- Sensors calibration.

Additional practical possibilities:

- Investigation of dynamic behaviour of stirred tank reactors in series.

- Determination of the ionic conductivities.

- Influence of flow rate.

- Work with just one reactor in continuous.

- Work with just one reactor in continuous with mixture effects.

- Work with three reactors in continuous.

- Effect of step input change.

- Response to an impulse change.

- Investigation of time constant using dead time coil.

Practices to be done with the Laminar Flow Reactor for QR (QRL):

- Calibration of the peristaltic pumps to obtain measurements of the reagent flow rate.

- Study and determination of the theoretical conversion of a laminar flow reactor.

- Obtention of the concentration change of sodium hydroxide during the reaction and its conversion.

- Determination of the residence time distribution (RTD) curve in a laminar flow reactor.

- Determination of the reactor’s residence time distribution.

- Determination of the reaction order and the rate constant.

- Sensors calibration.

Additional practical possibilities:

- Determination of the residence time distribution of the reactor.

- Effect of flow rate and feed concentration on the determination of flow pattern.

- Steady state conversion for a reaction with laminar flow.

- Effect of flow rate and feed concentration on the steady state conversion.

- Demonstration of the flow pattern in the reactor and comparison with the theoretical model.

- Effect of the temperature on the laminar flow characterisation.

- Determination of the steady state conversion of a second order reaction.

- Flow pattern characterisation in a laminar flow reactor.

- Conductivity measurement system: conductimeter.

Practices to be done with the Plug Flow Reactor for QR (QRP):

- Calibration of the reagents flows.

- Theoretical conversion of a plug flow reactor.

- Obtention of the concentration change of sodium hydroxide during the reaction and its conversion.

- Determination of the residence time distribution curve (RTD) in a plug reactor.

- Study the influence of the residence time in the conversion of the reaction.

- Determination of the order of reaction and the speed constant.

- Study of the reactor response to different perturbations at the reactor inlet: pulse and step change.

- Sensors calibration.

Additional practical possibilities:

- Determination of the residence time distribution of the reactor.

- Effect of flow rate and feed concentration on the determination of flow pattern.

- Effect of flow rate and feed concentration on the steady state conversion.

- Demonstration of the flow pattern in the reactor and comparison with the theoretical model.

- Determination of the steady state conversion of a second order reaction.

- Understanding the principles of tracer techniques in flow pattern characterisation.

- Conductivity measurement system: conductimeter.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SIMILAR UNITS AVAILABLE

Computer Controlled Chemical Reactors Training System

Chemical Reactors

SUPPLEMENTARY EQUIPMENT

Computer Controlled Chemical Reactors Training System

Base and Service Unit for QRQC

Isothermal Reactor with Stirrer

Isothermal Reactor with Stirrer and Distillation

Tubular Flow Reactor

Reactors with Stirrer in Series

Adiabatic and Isothermal Reactor

Base and Service Unit for QRC

Computer Controlled Continuous Stirred Tank Reactor for QRC

Computer Controlled Tubular Flow Reactor for QRC

Computer Controlled Batch Reactor for QRC

Computer Controlled Stirred Tank Reactors in Series for QRC

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences