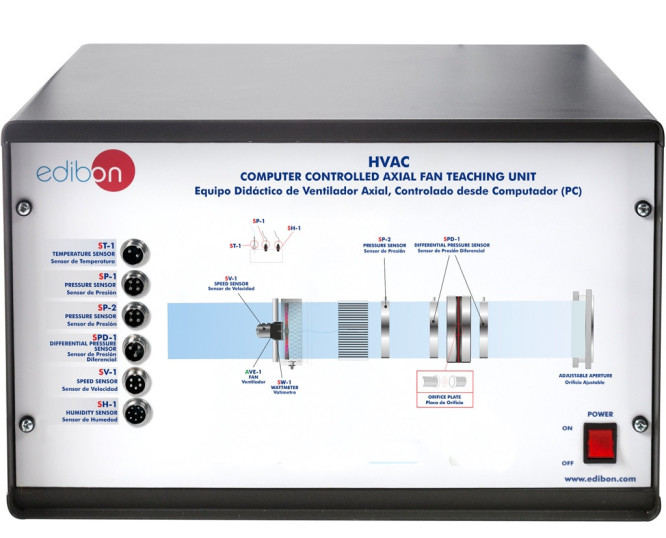

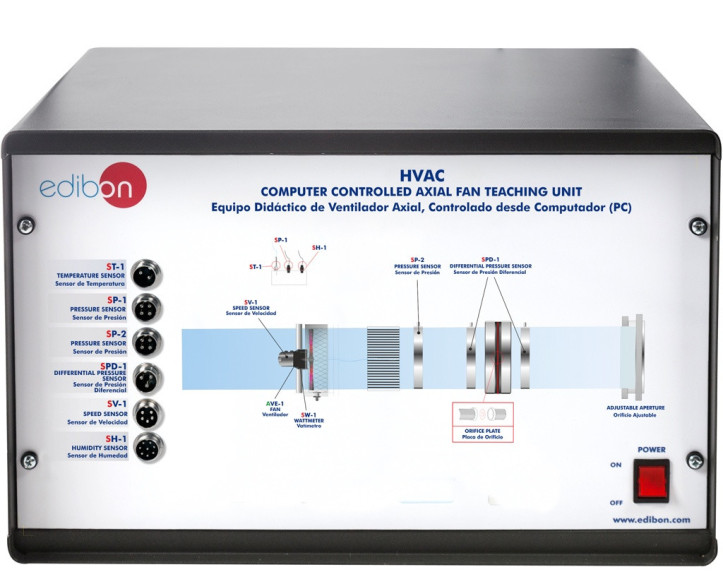

HVAC Computer Controlled Axial Fan Teaching Unit

INNOVATIVE SYSTEMS

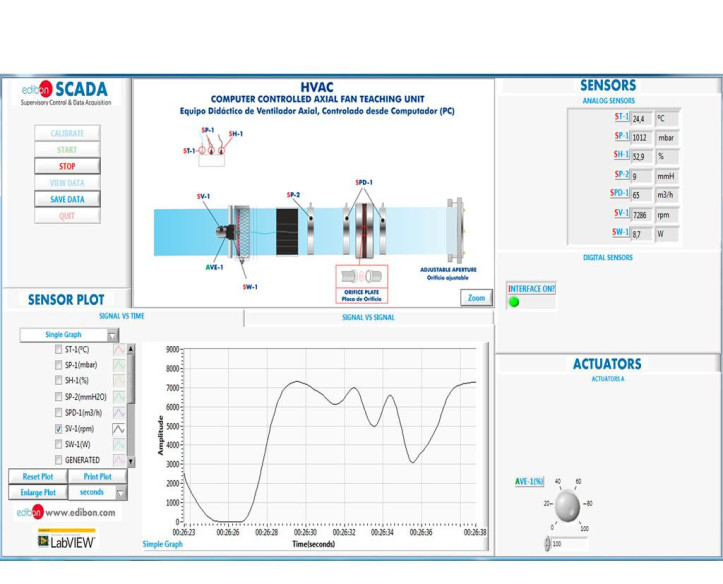

The Computer Controlled Axial Fan Teaching Unit, "HVAC", allows the observation, the study and the working process analysis of an axial-flow fan.

Expansions

Laboratories

RELATED NEWS

General Description

The Computer Controlled Axial Fan Teaching Unit, "HVAC", allows the observation, the study and the working process analysis of an axial-flow fan.

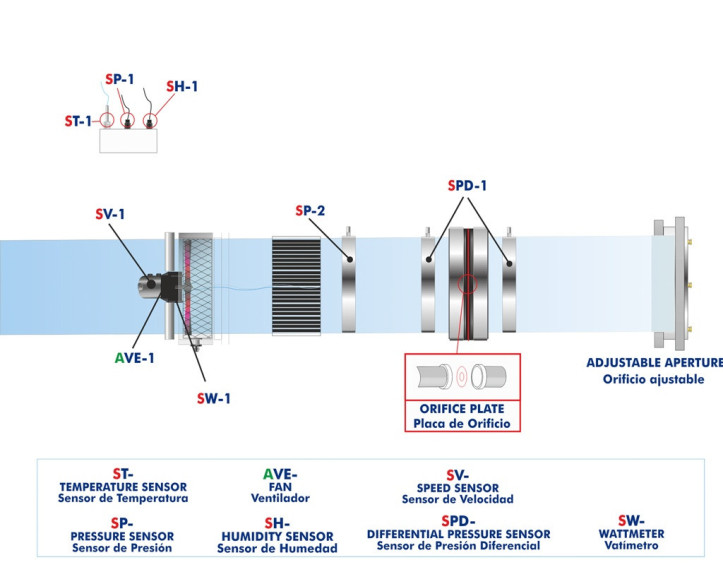

The main element of this unit is a computer controlled speed centrifugal fan, which is measured through a speed sensor, and a wattmeter determines the power consumed by the fan. The main tube of the unit is transparent. The air flow can be regulated through an adjustable oriffice at the inlet of the duct. It also has an oriffice plate for the calculation of the air flow with a differential pressure sensor.

There are also humidity, pressure and temperature measurements to know the inlet air conditions.

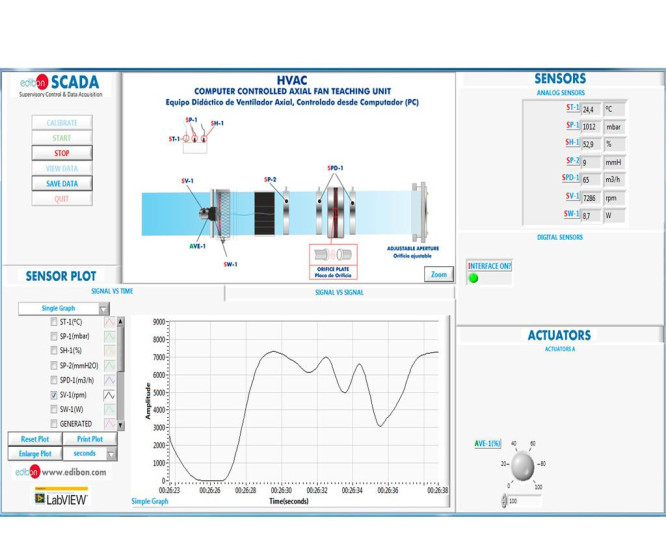

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Calculation of the flow by means of the orifice plate.

- Calculation of the flow through a measurement of the static, dynamic and total pressure with an adjustable orifice.

- Measurement of machine performance in terms static and total pressure, and motor input power, as an inlet flow function.

- Introduction to the scaling similitude law.

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Calculation of the characteristic curve of the axial fan at a constant speed according to the flow used by the adjustable aperture.

- Study of the axial fan regulation varying its turning speed.

- Study and comparison of the practical results and the results calculated by the students.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the HVAC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the HVAC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SIMILAR UNITS AVAILABLE

SUPPLEMENTARY EQUIPMENT

Computer Controlled Centrifugal Fan Teaching Unit

Centrifugal Fan Teaching Unit

Axial Fan Teaching Unit

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences