- Home

- Products

- 1.- PHYSICS

- ACADEMIC PROGRAMS

- HIGHER TECHNICAL EDUCATION

- FOOD ENGINEERING

- TOPOGRAPHIC ENGINEERING

- GEOLOGY

- FOREST ENGINEERING

- ENVIRONMENTAL ENGINEERING

- ECOLOGICAL ENGINEERING

- TEXTILE ENGINEERING

- ENGINEERING FOR AGRICULTURAL INDUSTRIES

- MECHANICAL ENGINEERING

- CHEMISTRY

- CHEMICAL ENGINEERING

- PROCESS ENGINEERING

- GEOLOGICAL, MINES AND OIL ENGINEERING

- PETROLEUM TRAINING CENTER

- NAVAL ENGINEERING

- AGRICULTURAL ENGINEERING

- ELECTRONICS ENGINEERING

- ARCHITECTURE

- COMPUTER SCIENCE & ENGINEERING

- NUCLEAR ENGINEERING

- AUTOMATIC ENGINEERING

- ENERGETIC ENGINEERING

- ENERGY TRAINING CENTER

- ELECTRICAL ENGINEERING

- SYSTEMS ENGINEERING

- AERONAUTICAL ENGINEERING

- OCEAN ENGINEERING AND MARINE SCIENCES

- PHYSICS

- INDUSTRIAL ENGINEERING

- INTERNATIONAL CENTER FOR TECHNICAL TRAINING, DEVELOPMENT AND RESEARCH

- MATERIALS ENGINEERING

- METALLURGICAL ENGINEERING

- CIVIL ENGINEERING

- TELECOMMUNICATION ENGINEERING

- THERMAL ENGINEERING

- TECHNICAL AND VOCATIONAL TRAINING

- ELECTRONICS

- COMMUNICATIONS

- ELECTRICITY

- COMPUTER SCIENCE

- AUTOMOTIVE TECHNOLOGY

- CIVIL ENGINEERING

- MECHANICAL AND MANUFACTURE

- MECHANICAL AND METAL

- FLUID MECHANICS

- REFRIGERATION AND AIR CONDITIONING

- INDUSTRIAL CHEMISTRY

- CHEMISTRY

- FOOD TECHNOLOGY

- AGRICULTURAL

- AGROINDUSTRY

- MAINTENANCE

- MARITIME AND FISHERY

- AERONAUTICAL MAINTENANCE

- INSTRUMENTATION AND CONTROL

- ENVIRONMENTAL

- TECHNOLOGY

- CONSTRUCTION TECHNOLOGY

- ELECTROMECHANICAL TECHNOLOGY

- STRUCTURAL DESIGN TECHNOLOGY

- INDUSTRIAL PRODUCTION TECHNOLOGY

- INFORMATION TECHNOLOGY

- QUALITY CONTROL

- ENERGY SYSTEMS TECHNOLOGY

- MINING AND PETROLEUM TECHNOLOGY

- NATURAL GAS TECHNOLOGY

- RENEWABLE ENERGY

- TELECOMMUNICATIONS TECHNOLOGY

- MECHANICAL TECHNOLOGY

- WIND TECHNOLOGY

- NUCLEAR TECHNOLOGY

- PROCESS CONTROL TECHNOLOGY

- GENERAL SERVICES TECHNOLOGY

- LABORATORY TECHNOLOGY

- AUTOMATION AND MECHATRONICS

- TRANSPORTATION AND LOGISTICS

- HIGHER TECHNICAL EDUCATION

- 2.- ELECTRONICS

- 3.- COMMUNICATIONS

- 4.- ELECTRICITY

- 5.- ENERGY

- 5.1.- SMART GRIDS AND POWER SYSTEMS

- 5.2.- MICROGRIDS

- 5.3.- RENEWABLE ENERGIES

- 5.3.1.- PHOTOVOLTAIC SOLAR ENERGY

- 5.3.2.- SOLAR THERMAL ENERGY

- 5.3.3.- WIND ENERGY

- 5.3.4.- MARINE ENERGY

- 5.3.5.- GEOTHERMAL ENERGY

- 5.3.6.- HYDRAULIC ENERGY

- 5.3.7.- BIOFUELS

- 5.3.8.- STORAGE SYSTEMS

- 5.3.9.- HYDROGEN FUEL CELLS

- 5.3.10.- STEAM TURBINES AND ORGANIC RANKINE CYCLES

- 5.3.11.- OTHER NON-CONVENTIONAL SYSTEMS

- 5.4.- CONVENTIONAL ENERGIES

- 5.5.- ENERGY STORAGE

- 5.6.- HIGH VOLTAGE AND ELECTRICAL PROTECTION SYSTEMS

- 5.7.- INSTALLATIONS AND MAINTENANCE

- 6.- MECHATRONICS & AUTOMATION

- 7.- MECHANICS

- 8.- FLUID MECHANICS

- 9.- THERMODYNAMICS & THERMOTECHNICS

- 9.1.- FUNDAMENTALS AND BASIC CONCEPTS OF THERMODYNAMICS

- 9.2.- HEATING, VENTILATION, AIR CONDITIONING AND HOT WATER

- 9.3.- HEAT PUMPS

- 9.4.- REFRIGERATION

- 9.5.- THERMAL HYDRAULIC PIPING SYSTEM

- 9.6.- HEAT TRANSFER

- 9.7.- HEAT EXCHANGERS

- 9.8.- THERMAL MACHINES

- 9.9.- INTERNAL COMBUSTION ENGINES

- 9.10.- INSTALLATIONS AND MAINTENANCE

- 10.- PROCESS CONTROL

- 11.- CHEMICAL ENGINEERING

- 11.1.- UNIT OPERATIONS

- 11.1.1.- FLUIDIZATION

- 11.1.2.- EVAPORATION

- 11.1.3.- BOILING

- 11.1.4.- DISTILLATION AND CRACKING

- 11.1.5.- EXTRACTION

- 11.1.6.- DIFFUSION

- 11.1.7.- DRYING AND COOLING

- 11.1.8.- ABSORPTION AND ADSORPTION

- 11.1.9.- ION EXCHANGE AND CORROSION

- 11.1.10.- CRYSTALLIZATION AND PYROLYSIS

- 11.1.11.- FILTRATION, SEDIMENTATION AND MIXING

- 11.1.12.- SOLIDS TREATMENT

- 11.2.- CHEMICAL REACTORS

- 11.1.- UNIT OPERATIONS

- 12.- FOOD & WATER TECHNOLOGIES

- 13.- ENVIRONMENT

- 14.- BIOMEDICAL ENGINEERING

- 14.1.- BIOMECHANICS

- 14.1.1.- MECHANICS FUNDAMENTALS KITS

- 14.1.2.- SIMPLE MACHINES

- 14.1.3.- STATICS AND DYNAMICS

- 14.1.4.- VIBRATIONS AND OSCILLATIONS

- 14.1.5.- TRIBOLOGY (FRICTION, WEAR, LUBRICATION)

- 14.1.6.- STRUCTURAL MECHANICS

- 14.1.7.- PHOTOELASTICITY AND STRAIN MEASUREMENT

- 14.1.8.- MECHANICAL TESTS

- 14.1.9.- THERMAL AND ACOUSTIC TESTS

- 14.2.- BIOMEDICAL ELECTRONICS

- 14.3.- BIOMEDICAL EQUIPMENT

- 14.1.- BIOMECHANICS

- LABORATORY ACCESSORIES

- CUSTOMIZED PILOT PLANTS

- MODULES

- EXPANSIONS

- LABORATORIES

- Lines of Business

- Technology

- Downloads

- About us

- News

- Contact us

Advancements in Mechatronics and Compumechatronics: Transforming Industrial Automation

Mechatronic Engineering: The Intersection of Mechanics and Electronics

Mechatronic Engineering represents the perfect synergy between mechanics and electronics. It's a holistic approach that integrates mechanical engineering, electronics, and automatic control to create intelligent systems and products. From industrial robots to production control systems, Mechatronic Engineering pushes the boundaries of innovation by combining mechanical functionality with electronic intelligence.

Automation and Programmable Logic Controllers (PLCs)

One of the fundamental pillars of Mechatronic Engineering is automation. Automated systems enable the execution of repetitive and complex tasks with high precision and efficiency. In this context, Programmable Logic Controllers, also known as PLCs, play an essential role. These programmable devices can control machines and industrial processes, optimizing production and reducing human errors.

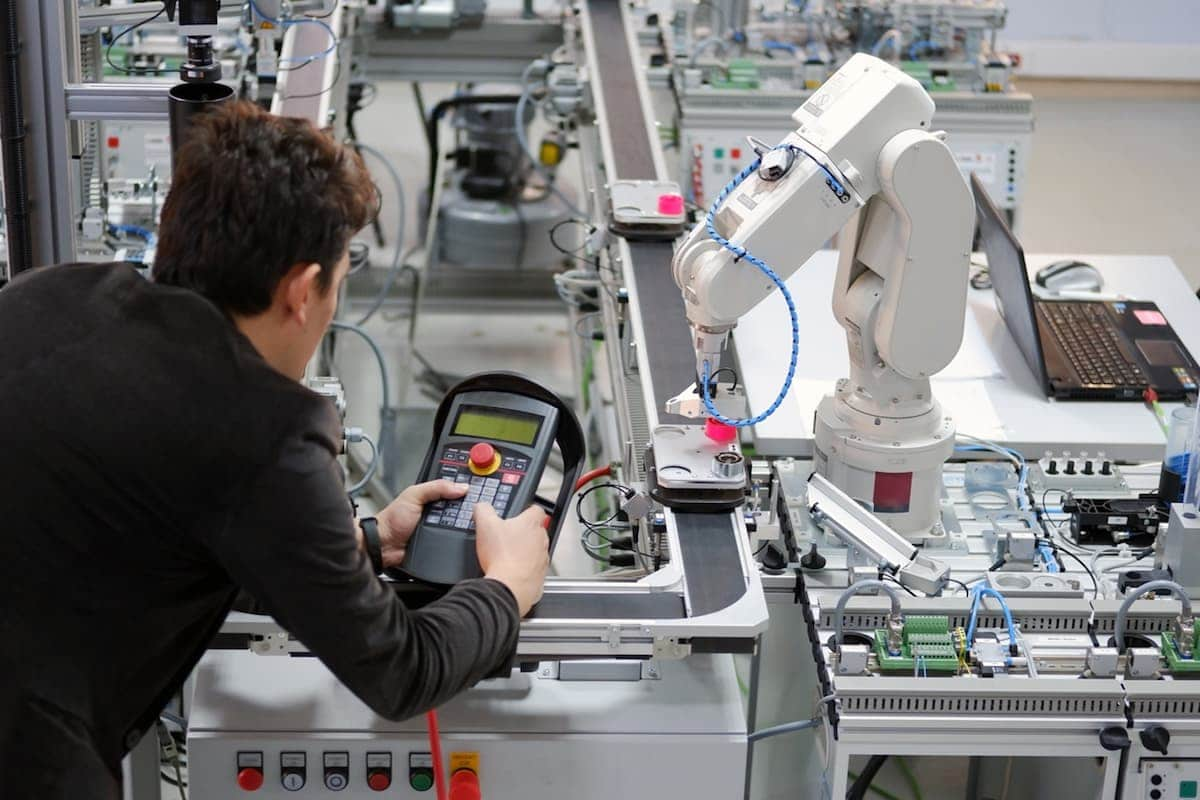

Servomotors and Assembly Robotics

Servomotors are key components in Mechatronic Engineering. These high-precision motors allow for exact control of position and speed in automated systems. In assembly robotics, servomotors are essential for creating robotic arms capable of efficiently and accurately assembling products. Assembly robots are a reality in many industries, from automotive to electronics, revolutionizing manufacturing processes.

Assembly Lines and Industrial Efficiency

Assembly lines are an iconic example of how Mechatronic Engineering is transforming the industry. Automation in assembly lines enables mass and rapid production of products, improving efficiency and reducing labor costs. The interconnection of machines and systems through the Internet of Things (IoT) and the focus of Industry 4.0 allows centralized monitoring and control, optimizing the entire production process.

The Compumechatronics Revolution

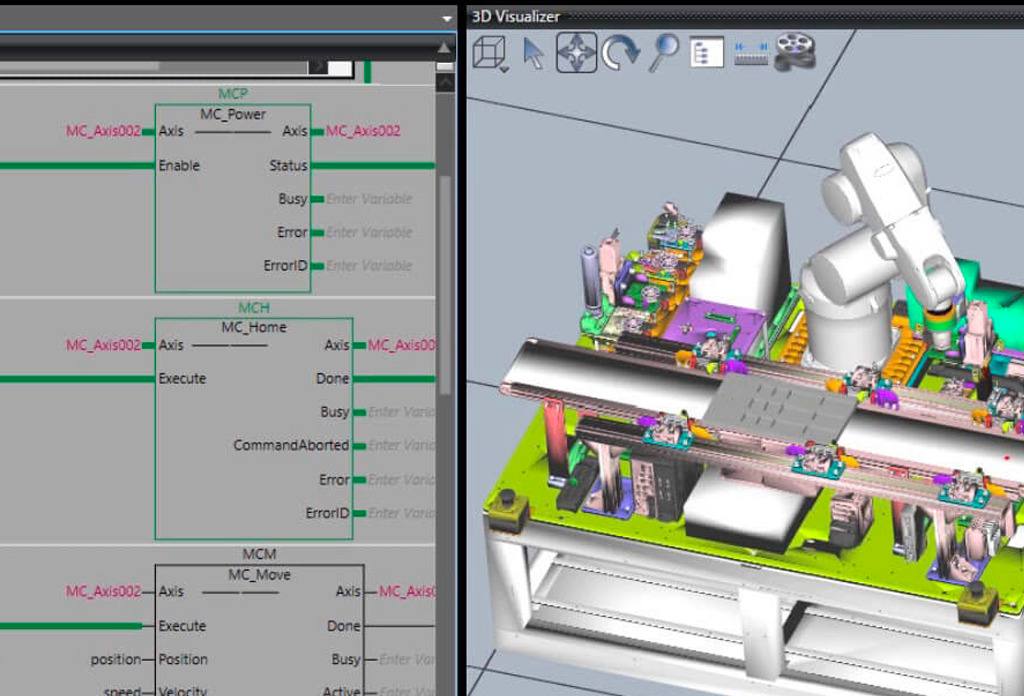

The term "compumechatronics" arises from the convergence of computing, mechanics, and electronics in Mechatronic Engineering. In the current era, compumechatronics has become a fundamental element in industrial automation. Programming and controlling mechatronic systems through advanced software have led to the creation of highly optimized processes and real-time data-driven decision-making.

Industry 4.0: The Intelligent Transformation of Production

Industry 4.0 represents a new era in industrial production, driven by connectivity and intelligent automation. The combination of technologies like IoT, Big Data, artificial intelligence, and cyber-physical systems is redefining the way factories and supply chains operate.

What Do We Do at EDIBON to Contribute to the Learning and Research of Mechatronic Engineers?

After many years of research and contact with professors and researchers, EDIBON has developed training and research equipment to assist in the learning process during the formative stage and to aid in research in this field.

For this reason, we offer training equipment that can be installed in laboratories, complementing theoretical studies to enhance learning and contribute to new lines of research.

Equipment like our Modular Regulation and Control System, Computer-Controlled "RYC/T", PANASONIC PLC Application "AE-PLC-PAN", SIEMENS PLC Application "AE-PLC-SIE", MITSUBISHI PLC Application "AE-PLC-MIT", OMRON PLC Application "AE-PLC-OMR", ALLEN BRADLEY PLC Application "AE-PLC-AB", or workstation applications such as a Parts Feeding Station "AE-PLC-APS" or flexible manufacturing systems with PLCs, among many others, aid in the learning process and in laboratories dedicated to research in all aspects related to mechatronic engineering.

Cookie preferences

Cookie preferences