TICT TICC 用シェル&チューブ熱交換器

革新的なシステム

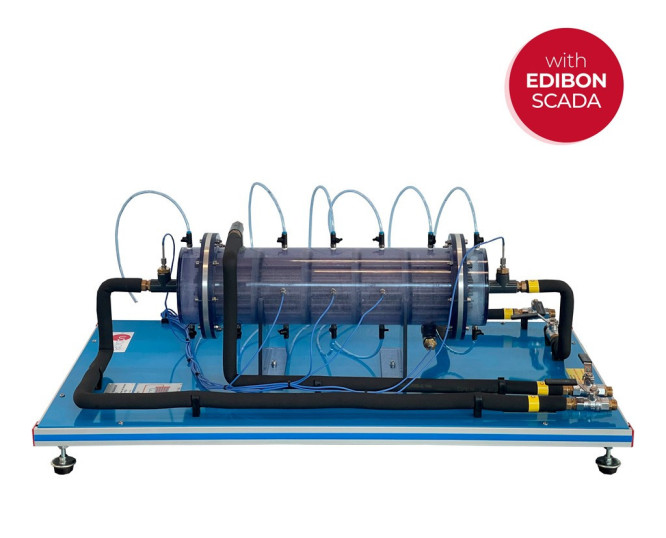

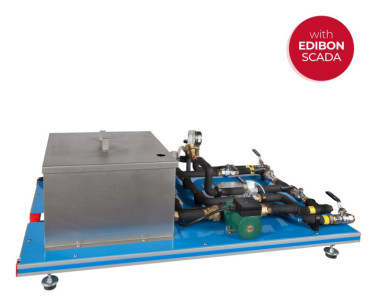

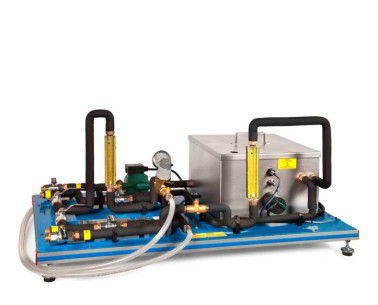

The Shell and Tube Heat Exchanger for TICC, "TICT", designed by EDIBON, provides a comprehensive environment for the study of heat transfer. It allows analysis of the overall energy balance, heat losses in parallel and counterflow configurations, as well as temperature distribution and exchanger efficiency.

拡張

研究室

関連ニュース

概要

The Shell and Tube Heat Exchanger for TICC, "TICT", designed by EDIBON, provides a comprehensive environment for the study of heat transfer. It allows analysis of the overall energy balance, heat losses in parallel and counterflow configurations, as well as temperature distribution and exchanger efficiency. Furthermore, it facilitates exploration of key parameters such as Reynolds number, Prandtl number, and Nusselt number.

This unit, comprising a series of tubes through which hot water flows and a space between the inner tubes and the casing for cooling water, offers detailed practices for studying and analyzing heat transfer. These practices include overall energy balance, heat loss studies, temperature distribution, and calculation of logarithmic mean temperatures. Additionally, the ε-NTU method is used to calculate the efficiency of the exchanger, and the influence of flow rate is investigated by analyzing Reynolds and Prandtl numbers. Nusselt number and convection heat transfer coefficients are also determined for each flow.

In summary, Shell and Tube Heat Exchanger for TICC, "TICT", provides students, teachers, and researchers with the opportunity to delve into the fundamental principles of heat transfer in shell and tube exchangers. With its innovative design, this unit offers a detailed understanding of the process.

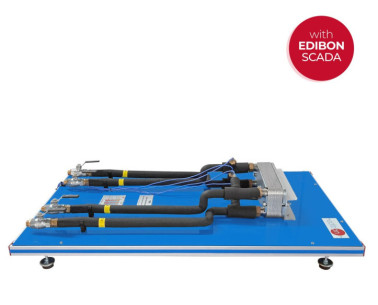

To work with this unit, the Base and Service Unit, "TIUS", is required, which provides key functions such as heating water using a thermostatic bath, pumping hot water, regulating and measuring the flow rates of cold and hot water, measuring the inlet and outlet temperatures of cold and hot water, as well as measuring the pressure drop in the heat exchanger.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Global energy balance in the heat exchanger and the study of losses.

- Obtainment and representation of the temperature distribution in a shell and tube exchanger.

- Calculation of the LMTD for a shell and tube exchanger.

- Calculation of the overall heat transfer coefficient in a shell and tube exchanger.

- Exchanger effectiveness determination. NTU Method.

- Influence of the flow in the heat transfer. Calculation of Reynolds number in the side of the tubes.

- Influence of the flow in the heat transfer. Calculation of Reynolds number in the side of the shell.

- Obtainment of Prandtl number for the tubes side.

- Obtainment of Prandtl number for the shell side.

- Obtainment of Nusselt number and the heat transfer coefficient by convection (hi) for the side of the tubes.

- Obtainment of Nusselt number and the heat transfer coefficient by convection (ho) for the side of the shell.

- Sensors calibration.

より実用的な練習をして、ユニットを完成させる

- Study of the heat transfer under counter-current and co-current flow conditions.

- Flow influence on the heat transfer. Reynolds number calculation.

- Study of the hysteresis of the flow sensor.

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user

利用可能な類似の機器

TICC用プレート熱交換器

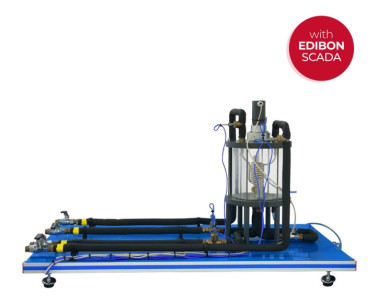

TICC 用同心管熱交換器

TICC 用ジャケット容器熱交換器

TICC 用コイル付きジャケット容器熱交換器

拡張同心管熱交換器(TICC 用)

TICC用の拡張プレート熱交換器

TICC用クロスフロー熱交換器

補完的な機器

コンピューター制御熱交換演習システム:

すべての "TI" タイプの熱交換器に共通の基本ベースおよびサービスモジュール

TICC 用同心管熱交換器

拡張同心管熱交換器(TICC 用)

TICC用プレート熱交換器

TICC用の拡張プレート熱交換器

TICC 用ジャケット容器熱交換器

TICC 用コイル付きジャケット容器熱交換器

TICCの乱流熱交換器

TICC用クロスフロー熱交換器

熱交換演習システム

すべての "TI..B" タイプの熱交換器に共通の基本ベースおよびサービスモジュール

品質

アフターサービス

クッキーの設定

クッキーの設定