EDSC コンピューター制御容器固体注入指導用装置

革新的なシステム

The Computer Controlled Solids Packaging Teaching Unit, "EDSC", designed by EDIBON, allows a practical analysis of the different dosing methods and the main stages of the solid product packaging process.

研究室

関連ニュース

概要

The Computer Controlled Solids Packaging Teaching Unit, "EDSC", designed by EDIBON, has been conceived for the complete study of the dosing, filling, and sealing process of solid products. Its design allows reproducing, at laboratory scale, the industrial operations of automatic packaging, offering a didactic and research tool focused on the analysis of dosing precision, filling efficiency, and process variable control.

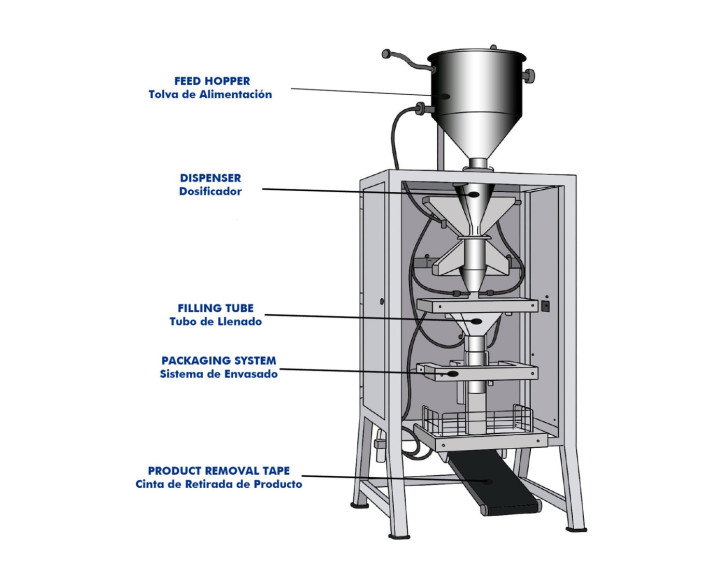

The process begins with the storage of the solid product in a feed hopper located above the dosing system. From this hopper, the material is transferred to the doser. The dosing system allows adjusting the quantity of product to be supplied.

Once the programmed quantity has been dosed, the product is introduced into the corresponding package through a filling funnel or tube. The unit includes level, weight, and container-presence sensors that ensure the correct operating sequence and allow the study of the interaction between control system signals. The closing or sealing of the container is carried out using the appropriate method according to the type of package.

All process phases feeding, dosing, filling, and sealing are controlled. Through the associated software, it is possible to visualize the main variables, record data, and analyze the system’s performance under different operating conditions. Thanks to this, the unit allows the study of the operating principles of solid dosing systems and all related variables.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Study of the general process of packaging solids.

- Observation of the behavior of the solid during flow and filling.

- Analysis of the overall performance of the packaging process.

より実用的な練習をして、ユニットを完成させる

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EDSC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EDSC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

補完的な機器

コンピューター制御スプレー式乾燥機

スプレー式乾燥機

コンピューター制御のスプレードライおよび冷却装置

コンピューター制御多目的処理シリンダー

コンピューター制御逆浸透・限外ろ過装置

コンピューター制御プレート&フレーム圧濾器

コンピューター制御水素化実験装置

コンピューター制御脱臭装置

Advanced Computer Controlled Deodorizing Unit

コンピューター制御連続循環式製油プラント

コンピューター制御プラスチック包装液体注入指導用装置

品質

アフターサービス

クッキーの設定

クッキーの設定