QRCC 固定床触媒反応器(スクロース加水分解用、PC制御)

革新的なシステム

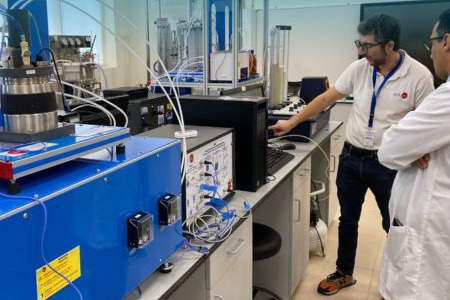

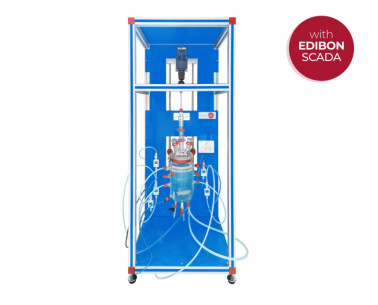

The Computer Controlled Fixed-Bed Catalytic Reactors for Sucrose Hydrolysis, "QRCC", designed by EDIBON, enables in-depth study of catalytic processes in the liquid phase through a fixed-bed reactor system, where the continuous hydrolysis of sucrose is performed using a solid catalyst immobilized inside the reactor.

拡張

研究室

関連ニュース

概要

Sucrose hydrolysis is a reversible reaction widely used at the industrial level to produce glucose and fructose. This process benefits greatly from catalysis, both chemical and enzymatic, and is a representative example of using fixed-bed reactors in continuous processes.

The Computer Controlled Fixed-Bed Catalytic Reactors for Sucrose Hydrolysis, "QRCC", designed by EDIBON, enable practical, controlled study of the hydrolysis reaction under industrial-like conditions. The design of the Computer Controlled Fixed-Bed Catalytic Reactors for Sucrose Hydrolysis, "QRCC", facilitates the analysis of different types of catalysis (chemical and enzymatic) and the impact of operational variables such as temperature, flow rate, and catalyst particle size.

The unit includes three fixed-bed reactors: two dedicated to chemical catalysis, using the same catalyst (ion-exchange resins) with different particle sizes, and a third reactor for enzymatic catalysis, utilizing an immobilized enzyme to carry out sucrose hydrolysis.

The reaction occurs at controlled temperatures between 50 °C and 60 °C, maintained by a hot-water recirculation system through jacketed reactors. Temperature is precisely regulated via PID control managed through the unit software.

Sucrose solution feeding is performed with a variable-speed peristaltic pump, also software-controlled. The resulting solution is collected in a final-product flask and can be analyzed with a spectrophotometer integrated into the system and connected to the unit’s interface.

Optionally, the Computer Controlled Flow Injection Analysis (FIA) Unit, "QRCC-IF" can be included, allowing continuous measurement of the reaction conversion degree.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

付属品

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Study of the principles of catalytic fixed-bed reactors.

- Effect of the variation in the particle’s size in the effectiveness of a fixed-bed reactor.

- Comparison of chemical and biological (enzymic) catalysis.

- Checking the influence on different variables (feed flow, temperature of reaction, reagents concentration) on the obtained final product.

- Spectrophotometer calibration.

- Using the spectrophotometer and product analysis.

- Study of the "FIA" Flow Injection Analysis technique and principles (with "QRCC-IF" recommended accessory).

- Examination of the reproducibility and sensitivity of the "FIA" analysis method as a function of the flow rate and sample concentration (with "QRCC-IF" recommended accessory).

より実用的な練習をして、ユニットを完成させる

- Sensors calibration.

- Studies of steady and unsteady state catalysis.

- Flow characterisation in a fixed-bed.

- Mass balances.

- Determination of steady state and unsteady state kinetics of a catalytic fixed-bed reactor.

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the QRCC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the QRCC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

利用可能な類似の機器

スクロース加水分解用固定床触媒反応器

補完的な機器

化学反応器トレーニングシステム、コンピュータ制御(PC)

QRQC用基礎およびサービスユニット

等温攪拌反応器

等温攪拌反応器と蒸留

管流反応器

連続攪拌タンク反応器

断熱および等温反応器

化学反応器、コンピュータ制御(PC)

QRCのベースユニットとサービスユニット

連続タンク攪拌反応器(QRC用)、コンピュータ制御(PC)

管流反応器(QRC用)、コンピュータ制御(PC)

バッチ反応器(QRC用)、コンピュータ制御(PC)

品質

アフターサービス

クッキーの設定

クッキーの設定