QREC 酵素バッチ反応器、コンピュータ制御(PC)

革新的なシステム

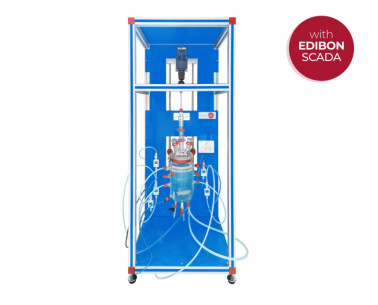

The Computer Controlled Batch Enzyme Reactor "QREC" is an unit designed to perform the glucose isomerisation reaction catalyzed by glucose isomerase in a batch reactor.

拡張

研究室

関連ニュース

概要

The Computer Controlled Batch Enzyme Reactor, "QREC", has been designed by EDIBON to perform the glucose isomerisation reaction catalyzed by glucose isomerase in a batch reactor. This unit allows to demonstrate batch enzyme kinetics and enzyme characteristics.

The "QREC" is divided in three main sections: stirred batch reactor, coil heat exchanger and polarimeter.

The isomerisation reaction takes place inside the batch reactor, where a fixed catalyst basket immobilizes the enzyme (biological catalyst) and a stirrer increase the efficiency of the mixture. This reactor has a coil through which hot water circulates to favor the reaction. It is made of glass to facilitate the visualization of the reaction. A temperature sensor measures the temperature in the reactor. It can be controlled with the PID control through the control software. This temperature sensor and a pH sensor allow to study the influence of environmental conditions on enzyme activity. The unit allows to adjust the pH value by adding acid and base solutions.

A continuous sampling loop driven by a peristaltic pump takes a small volume of solution from the reactor. This solution is transferred to the coil heat exchanger, where it is cooled. This heat exchanger is made of acrylic material and glass and includes a stirrer, a temperature sensor to measure the temperature in the heat exchanger and other sensor to measure the temperature of the solution at the outlet of the heat exchanger.

The cool solution passes through a polarimeter, where the angle of rotation of the polarized light is measured. From this measurement, the concentration of glucose and fructose can be calculated.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Study of the principles of catalytic batch reactors.

- Study of the type of enzyme in the specific activity of a catalytic batch reactors.

- Determination of optical rotation of fructose and glucose.

- Demonstration of Biot's law.

- Study of the principles of polarimetry.

- Determination of the glucose and fructose concentration by polarimetry.

- Study of the influence of different variables (solution concentration, reaction temperature, reaction pH) on enzyme activity.

- Determination of Michaelis-Menten rate equation constants in a batch enzyme reactor.

- Determination of the enzyme specific activity through Michaelis-Menten equation and Lineweaver-Burke plots.

- Study of the principles of batch enzyme kinetics.

- Sensors calibration.

より実用的な練習をして、ユニットを完成させる

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the QREC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the QREC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

補完的な機器

QRQC用基礎およびサービスユニット

等温攪拌反応器

等温攪拌反応器と蒸留

管流反応器

連続攪拌タンク反応器

断熱および等温反応器

化学反応器、コンピュータ制御(PC)

QRCのベースユニットとサービスユニット

連続タンク攪拌反応器(QRC用)、コンピュータ制御(PC)

管流反応器(QRC用)、コンピュータ制御(PC)

バッチ反応器(QRC用)、コンピュータ制御(PC)

品質

アフターサービス

クッキーの設定

クッキーの設定