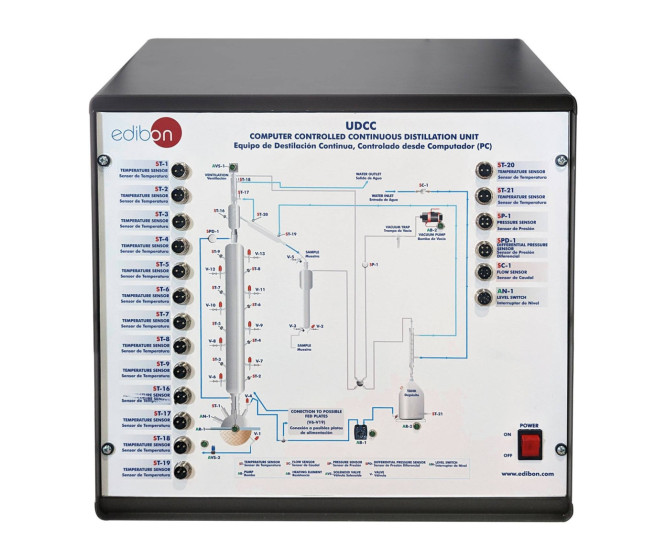

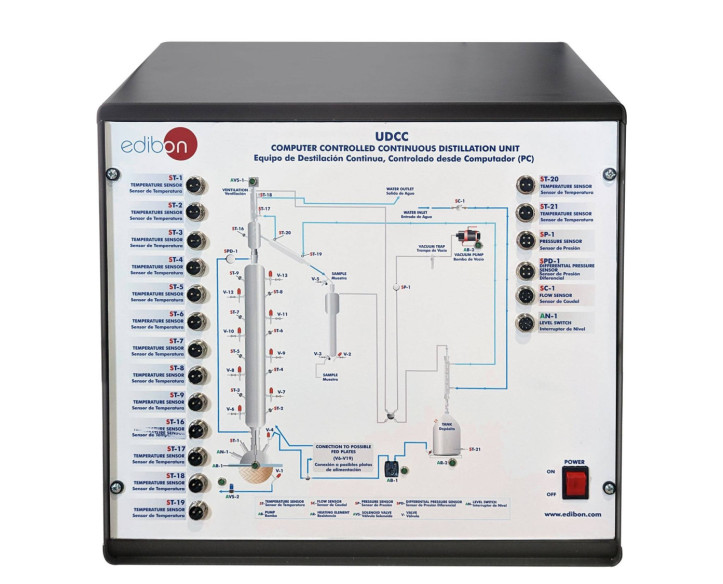

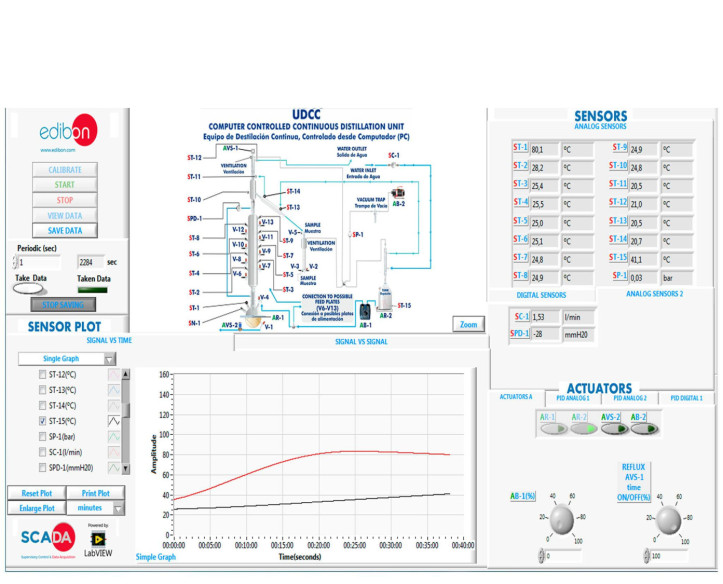

UDCC Computer Controlled Continuous Distillation Unit

INNOVATIVE SYSTEMS

The Computer Controlled Continuous Distillation Unit, "UDCC", designed by EDIBON, is a powerful laboratory solution for the study of variables affecting the distillation process.

Expansions

Laboratories

RELATED NEWS

General Description

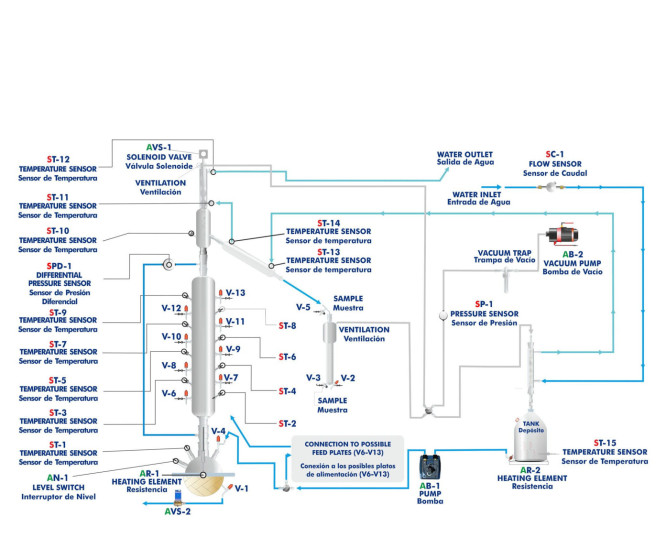

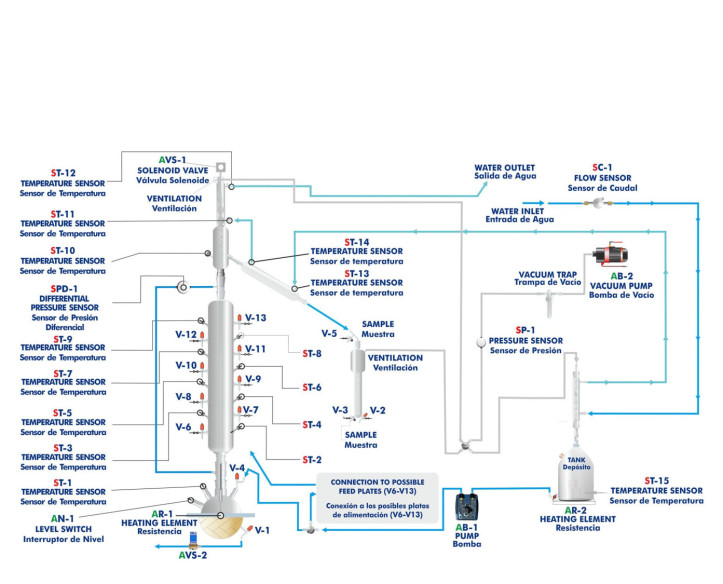

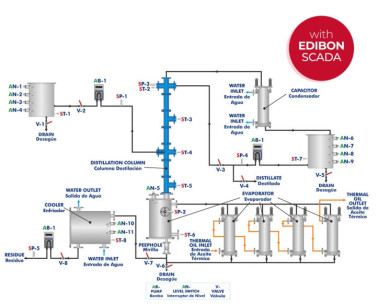

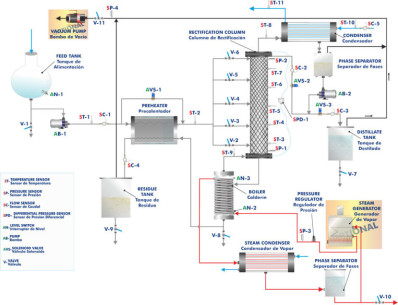

The Computer Controlled Continuous Distillation Unit, "UDCC", is basically composed by a boiler on which different types of interchangeable columns can be adapted (plate and filling (Raschig rings)). An eight plate column, a reflux system, a tank for distillation, a vacuum pump and a feeding pump (for continuous feeding) are included.

The steam that goes to the head of the column is sent to a total condenser. The cooling water flow that crosses the condenser is regulated and indicated in a flow sensor. Distillation can be carried out at low pressures with the help of an adjustable vacuum pump. The pressure loss in the column can be measured with a pressure sensor.

It allows continuous operation and batch operation.

For proceeding to continuous feeding, a pump that can inject the substance directly into the boiler or in any of the plates is available.

The temperatures of the system are measured by sensors placed in strategic positions.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Preparation of solutions.

- Analytic valuation techniques.

- Filling of the column.

- Batch operation. Continuous operation.

- Obtaining the McCabe-Thiele diagram. Without reflux.

- Obtaining the number of plates. Without reflux.

- Efficiency calculations. Without reflux.

- Variation of the composition of the distilled product: constant reflux ratio.

- Constant composition of the distilled product: variation of reflux ratio.

- Constant composition of the distilled product: constant reflux ratio.

- Continuos feeding of the column.

- Mass and energy balances across the system.

- Plates fluid dynamics studies, including load loss and column flooding.

- Study of the feed temperature effect on the continuos processes.

- Calculation of the theoretical number of floors in the plates columns, and the equivalent height of the theoretical floor (HEPT) in the Raschig rings columns.

- Pursuit of the temperatures in all plates in the column (Plates columns).

- Study of the rectification efficiency at different pressures.

- Effect of feed pre-heat.

- Effect of feed position.

- Demonstration of azeotropic distillation.

- Work different heating contribution with regulation by the computer.

- Studies of heating interchange in glass refrigerators.

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Dosing pump calibration.

- Study of PID controls.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the UDCC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the UDCC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SIMILAR UNITS AVAILABLE

Continuous Distillation Unit

Batch Distillation Unit

SUPPLEMENTARY EQUIPMENT

Computer Controlled and Touch Screen 4 l/h Corrosive Solvent Recovery Distillation

Computer Controlled and Touch Screen 12 l/h Corrosive Solvent Recovery Distillation

Advanced Computer Controlled Continuous Destillation Unit

Continuous Distillation Unit

Computer Controlled Batch Distillation Unit

Batch Distillation Unit

Computer Controlled Cracking Column

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences