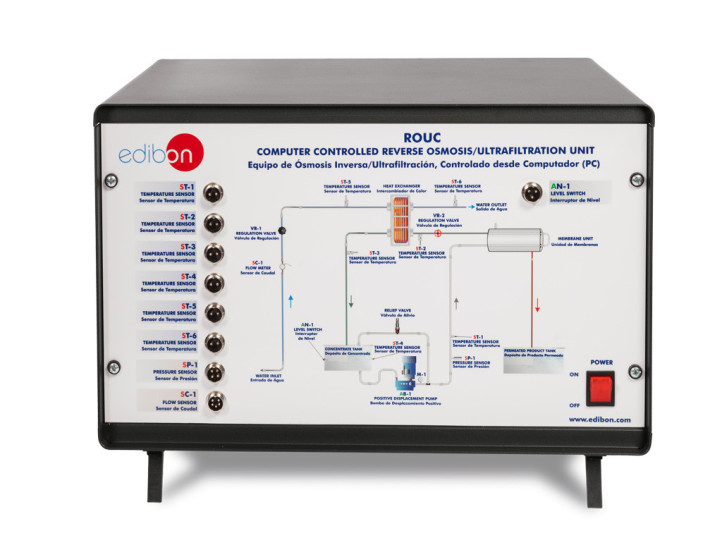

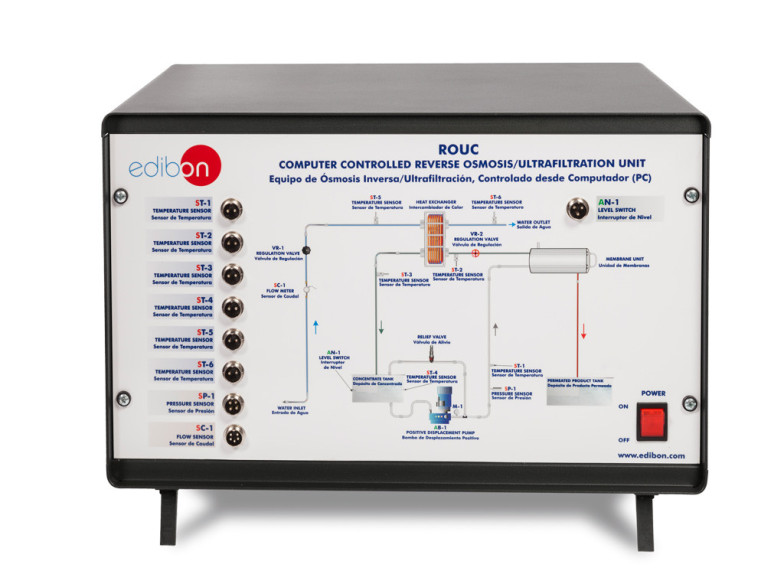

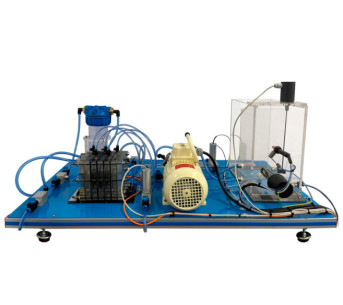

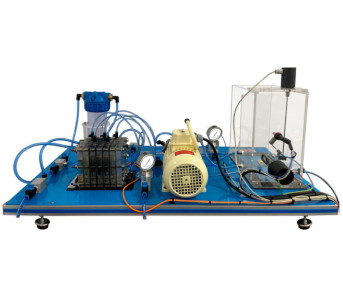

ROUC Computer Controlled Reverse Osmosis/Ultrafiltration Unit

INNOVATIVE SYSTEMS

The Computer Controlled Reverse Osmosis/Ultrafiltration Unit, "ROUC", allows the practical study of the ultrafiltration and reverse osmosis techniques.

Expansions

Laboratories

RELATED NEWS

General Description

The Computer Controlled Reverse Osmosis/Ultrafiltration Unit, "ROUC", performs a tangential flow filtration process, which is a system that prevents the formation of impurities sediments that reduces its capacity.

Two variable of the effluent must be known to perform reverse osmosis and ultrafiltration separation practical exercises:

- Chemical composition of the fluid.

- The membrane characteristics to know the most suitable one for the desired process.

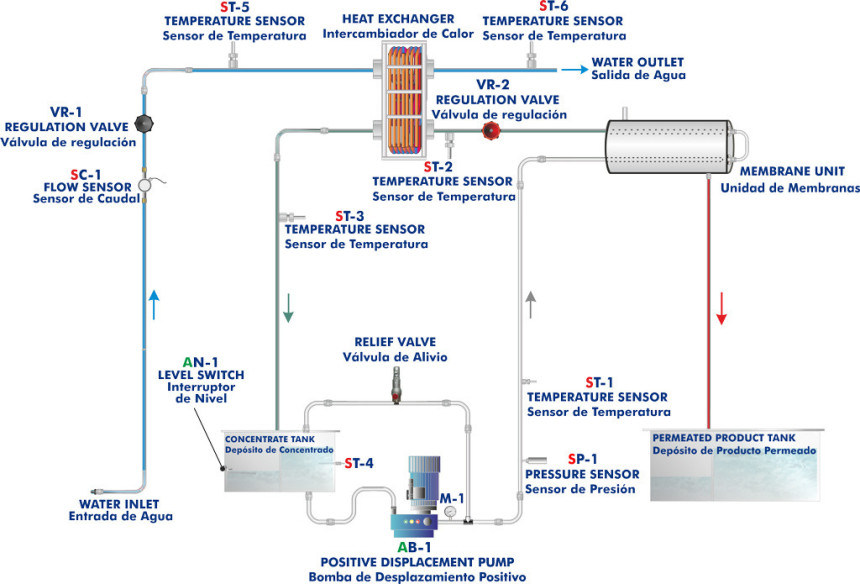

A computer controlled three piston positive displacement pump impels the effluent to the membranes. The motor of the pump is controlled by a variable frequency drive for obtaining different flows in function of the required separation process. As it is a positive displacement pump the flow obtained will be directly proportional to the motor speed.

The pump supplies the effluent to both tubular membranes connected in series and lodged in a membrane module. The solution to be treated flows inside the tubes, the permeate flows radially from the inside to the outside of the tubes and the waste is obtained at the end ofthe tubes.

The effluent impelled by the pump will receive heat from it, increasing its temperature. The permeate will be collected in a final product tank. The concentrate will go back to the initial tank to be treated again as effluent, but due to the temperature rise this concentrate will flow through a plate heat exchanger.Membranes with different weight cut-off points are included. They only differ in length and number from the ones installed in a real plant.

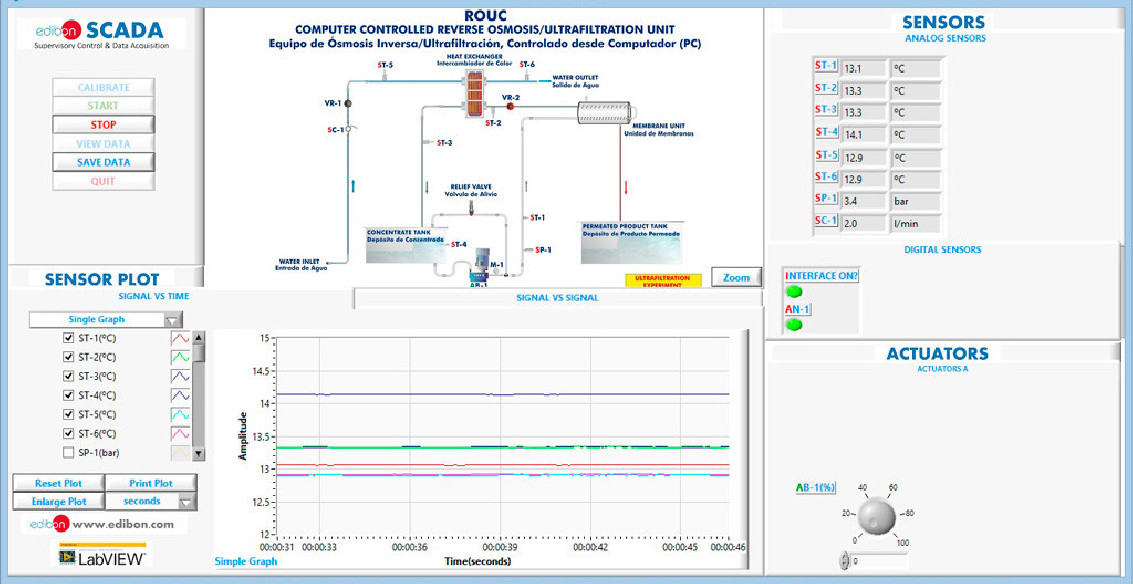

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Practical training in ultrafiltration and reverse osmosis processing techniques.

- Protein standardization in the production of fermented milk products such as concentration of skimmed milk for yogurt production.

- Pre-concentration of milk for cheese manufacture.

- Concentration of fruit juices.

- Clarification of fruit juices.

- Water potabilization.

- Demonstration of the effect of varying the following process parameters on separation performance:

- Process pressure.

- Product flow rate.

- Process temperature.

- Sensors calibration

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Applications of concentration, clarification, fractionation and standardization of milk, fruit juices, vegetables juices, etc.

- Treatment of effluent.

- Membrane cleaning and maintenance.

- Enzyme, antibiotics and organic acids' recovery in permeate.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the ROUC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the ROUC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

SUPPLEMENTARY EQUIPMENT

Computer Controlled and Touch Screen 1000 l Semicontinuous Centrifugal Separator

Computer Controlled Continuous and Batch Filtration Unit

Continuous and Batch Filtration Unit

Computer Controlled Plate and Frame Filter Press

Computer Controlled Deep Bed Filter Unit

Deep Bed Filter Unit

Sedimentation Study Unit

Computer Controlled Sedimentation Tank

Sedimentation Tank

Computer Controlled Drainage and Seepage Tank

Drainage and Seepage Tank

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences