Once again, EDIBON had the honor of participating in one of the most significant international events in the field of engineering education: the ASEE Annual Conference and Exposition 2025, organized by the American Society for Engineering Education (ASEE).

In a world where climate change represents one of the greatest threats to our future, carbon dioxide (CO2) adsorption has become an urgent priority. The increasing concentration of CO2 in the atmosphere, primarily driven by human activities such as fossil fuel combustion and deforestation, has...

At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

In a world where energy demand continues to rise and non-renewable resources are rapidly depleting, the need for sustainable, environmentally friendly solutions has never been more urgent. The circular economy and the use of organic biomass to produce biofuels are emerging as key answers to...

Direct Air Capture (DAC) is an innovative technology that removes CO₂ directly from the air using chemical reactions with liquid solvents or solid absorbents. Despite challenges such as high costs and energy consumption, DAC offers a potential solution to reduce atmospheric CO₂ concentrations and...

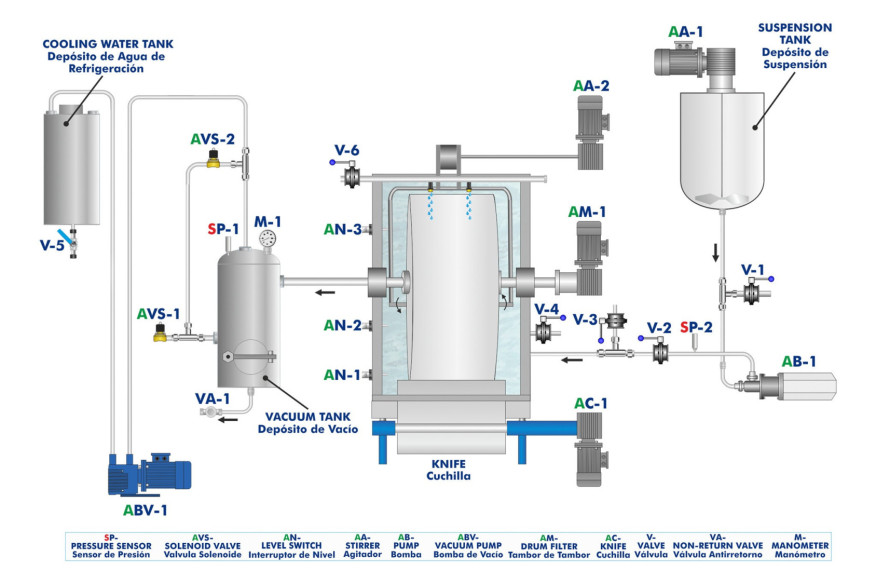

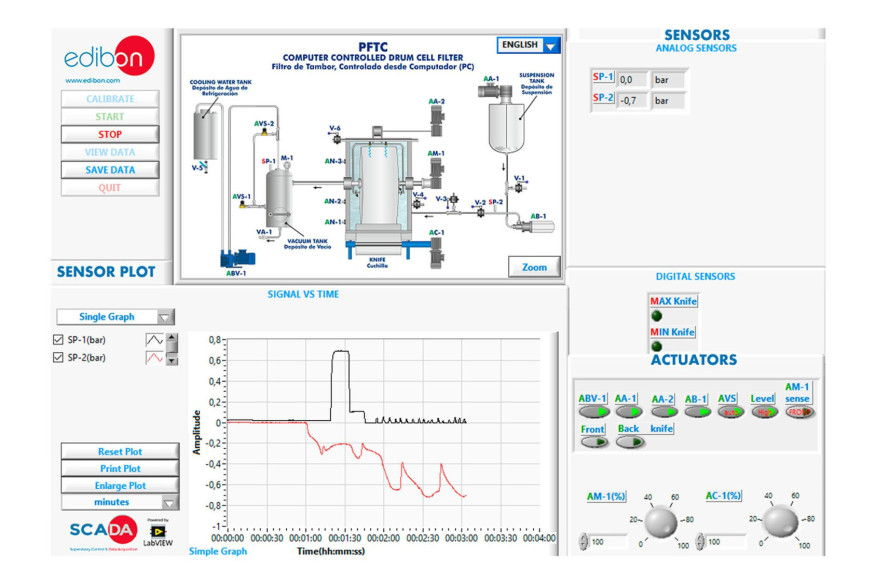

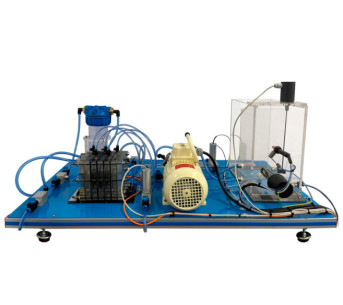

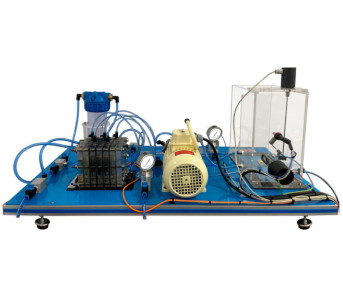

Ensuring access to safe drinking water involves complex processes and advanced technologies. Key components of a treatment plant include intake structures, coagulation, flocculation, sedimentation, filtration, disinfection, storage, and distribution. Modern systems use reverse osmosis, UV...

Cookie preferences

Cookie preferences