At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-A Part Feeding Workstation

INNOVATIVE SYSTEMS

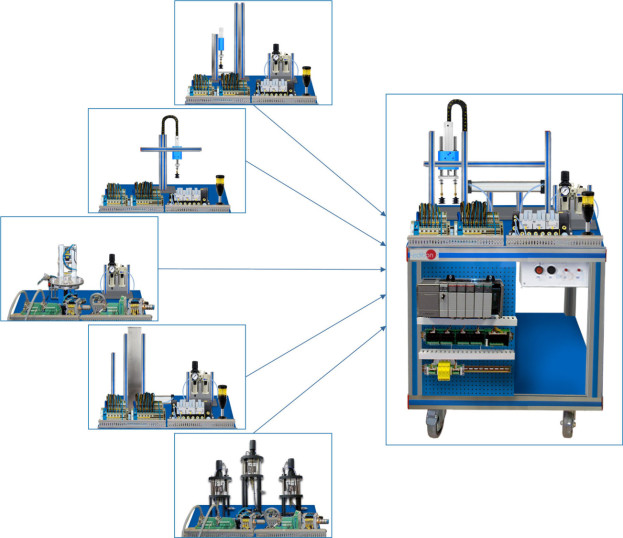

The Feeding Workstation for Pieces, "AE-PLC-A", has been designed by EDIBON to study the pieces feeders with quality control of the computer integrated manufacturing systems.

RELATED NEWS

General Description

The "AE-PLC-A" is a feeder workstation commanded by a PLC that provides pieces to the system. The "AE-PLC-A" keeps the pieces in a vertical storage, the workstation take the pieces one by one and place at the quality control zone. The system verifies the pieces and if the piece is correct a manipulator take the piece and place at the exit zone. If the piece is not correct, the system discard the piece.

The "AE-PLC-A" workstation is designed as a modular system to facilitate the understanding of the unit. The main components are:

- The PLC: is composed by the CPU limit and all extra modules needed to perform a corrent working of the workstation and all the extra modules needed to perform a correct working of the workstation.

- The control panel: with start/stop button, emergency push button, reset button, light indicators to show current state of the process, etc.

- The pneumatic circuit: contains the required solenoid valves, the vacuum components, the filters and regulators to assure the appropriate working of the unit.

- The workstation: is composed by real industrial components used by the industrial feeder systems such as reed sensors, presence sensors, rotary actuators, vacuum cups, etc.

The "AE-PLC-A" is an independent workstation that can work alone and/or in conjunction with other workstation to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Introduction to flexible manufacturing system (FMS).

- Introduction to pneumatics and electro-pneumatics.

- Introduction to vacuum technology.

- Study of the sensor detection.

- Configuration of a pneumatic application.

- Manual control of a Feeding system.

- Automatic control of a Feeding system.

- Change the parameters of the Feeding process.

- Optimization of the process time.

- Study and analysis of the faults inserted in the process with the fault generation module.

SIMILAR UNITS AVAILABLE

6.2.5.1.- PIECES FEEDING WORKSTATIONS APPLICATIONS

AE-PLC-MA

The "AE-PLC-MA" is a Multiple Pieces Feeder Workstation commanded by a PLC, which provides three different types of pieces to be assembled in one piece by the industrial robot of the "AE-BR" unit.The "AE-PLC-MA" contains an input pieces area, an...

6.2.5.1.- PIECES FEEDING WORKSTATIONS APPLICATIONS

AE-PLC-APS

Part Feeder Workstation

The Pieces Feeder Workstation, "AE-PLC-APS", is a unit that works with pneumatics and electro-pneumatics technologies.The function of the "AE-PLC-APS" is to supply pieces and to verify them, if they are acceptable.The pieces will be supplied one...

6.2.5.1.- PIECES FEEDING WORKSTATIONS APPLICATIONS

AE-PLC-DS

Parts Distribution Workstation

The "AE-PLC-DS" is a feeder workstation commanded by a PLC, which provides pieces made in different color and materials to the system. The "AE-PLC-DS" keeps the pieces in a vertical storage, the workstation take the pieces one by one and place...

SUPPLEMENTARY EQUIPMENT

6.2.5.1.- PIECES FEEDING WORKSTATIONS APPLICATIONS

AE-PLC-APS

Part Feeder Workstation

The Pieces Feeder Workstation, "AE-PLC-APS", is a unit that works with pneumatics and electro-pneumatics technologies.The function of the "AE-PLC-APS" is to supply pieces and to verify them, if they are acceptable.The pieces will be supplied one...

6.2.5.1.- PIECES FEEDING WORKSTATIONS APPLICATIONS

AE-PLC-MA

Multi-Part Feeding Workstation

The "AE-PLC-MA" is a Multiple Pieces Feeder Workstation commanded by a PLC, which provides three different types of pieces to be assembled in one piece by the industrial robot of the "AE-BR" unit.The "AE-PLC-MA" contains an input pieces area, an...

6.2.5.1.- PIECES FEEDING WORKSTATIONS APPLICATIONS

AE-PLC-DS

Parts Distribution Workstation

The "AE-PLC-DS" is a feeder workstation commanded by a PLC, which provides pieces made in different color and materials to the system. The "AE-PLC-DS" keeps the pieces in a vertical storage, the workstation take the pieces one by one and place...

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences