PCGC コンピューター制御ガスサイクロン

革新的なシステム

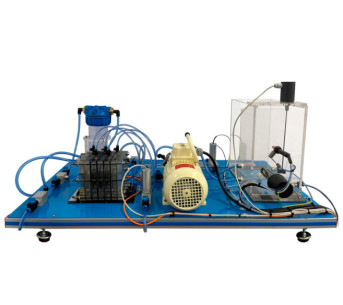

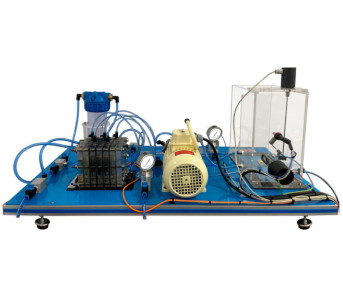

The Computer Controlled Gas Cyclone, "PCGC", has been designed by EDIBON to study the separation of solid particles from an air current through a cyclone.

拡張

研究室

関連ニュース

概要

The Computer Controlled Gas Cyclone, "PCGC", has been designed by EDIBON to study the separation of heterogeneous mixtures through a cyclone, specifically those made up of a thin material (4 μm – 400 μm) and an air flow. The cyclone, the main component of this system, separates the solid particles of the air flow so it comes out clean.

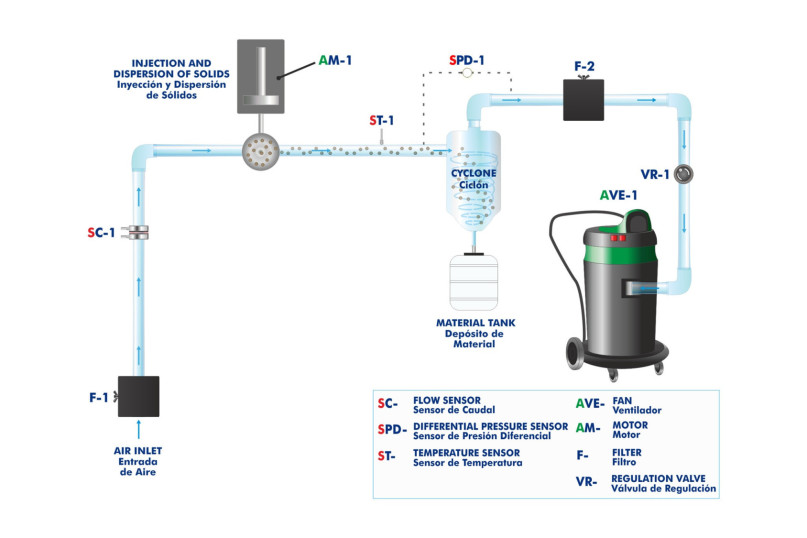

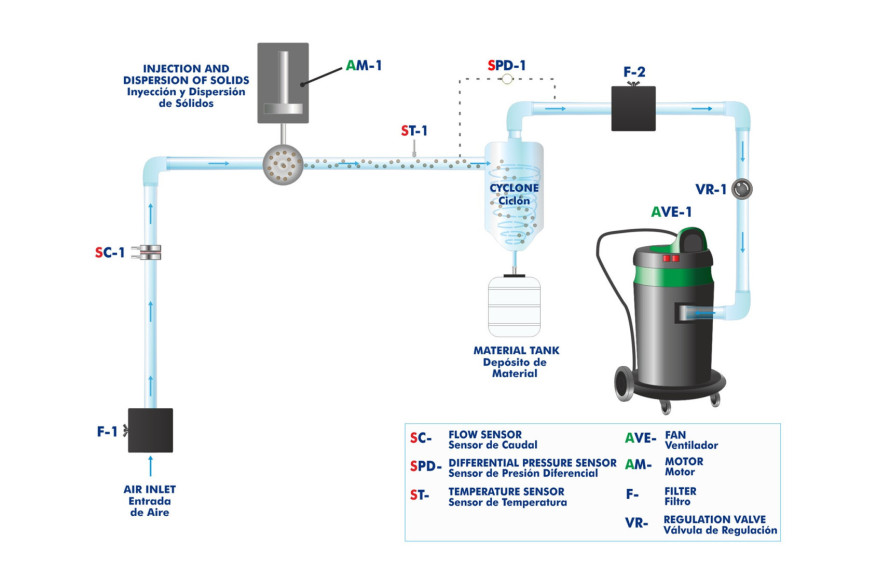

A fan aspirates generating the air flow through the conduit, crossing a flow sensor that detects the air flow. The speed of the fan can be controlled from the computer. It also includes a valve to control the speed manually. A filter prevents other unwanted particles from entering, guaranteeing a good quality air. Next, a solid dispersion motor system impels the solids to the conduit, where they are mixed with the air flow.

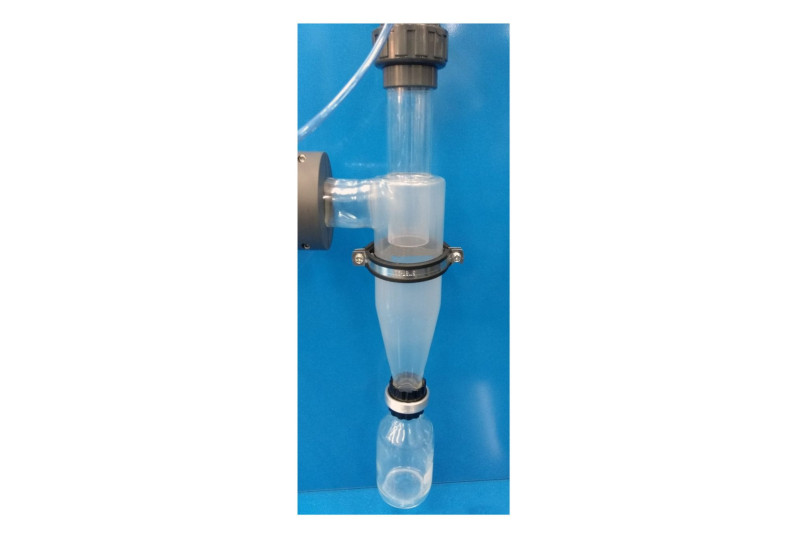

When the mixture is ready the flow reaches the cyclone separator. The flow temperature is measured before entering. The air flows in a helical pattern, starting from the highest of the cyclone to the lowest and ending in an ascending central flow that exits through the outlet pipe (in the uppermost part of the cyclone). The larger and denser particles in the rotary flow have too much inertia to follow the strong upward curve in the bottom of the cyclone. They collide with the wall and fall to the lowest part of the cyclone, where they are collected in a glass tank.

A differential pressure sensor allows the study of the pressure drop between the inlet and the outlet of the cyclone.

Finally, air is filtered again at the end of the conduit to guarantee that there are no suspended particles left.

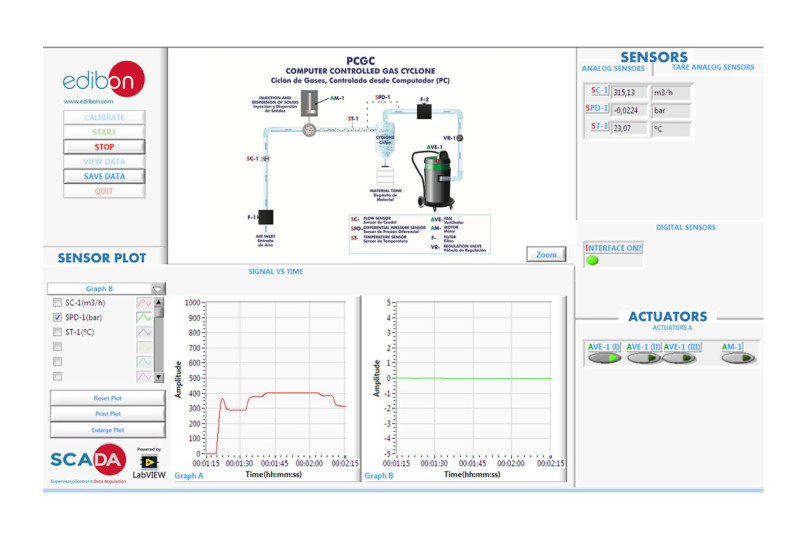

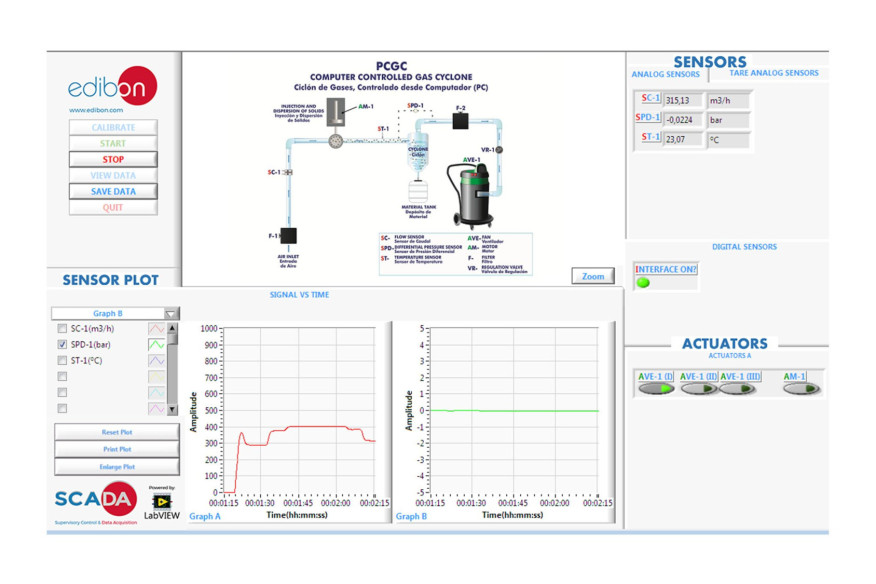

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Study of the operation of a cyclone separator.

- Study of the size of solids or air flow versus pressure drop in the cyclone.

- Calculation of the cyclone separation efficiency and variation of this value in function of the air flow and the amount of added solids.

- Comparison of the cyclone efficiency experimentally obtained with the theoretical calculations.

- Study of the pressure drop at the inlet and outlet of the cyclone.

- Comparison of the pressure drop experimentally obtained with the theoretical calculations.

- Determination of the separation size (spectrophotometer required).

- Influence of the air flow and the amount of added solids on the separation size (spectrophotometer required).

- Sensors calibration.

より実用的な練習をして、ユニットを完成させる

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PCGC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PCGC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

補完的な機器

コンピューター(PC)およびタッチスクリーンで制御される1000リットルの半連続遠心分離器

コンピューター制御連続バッチ式フィルター実験装置

連続バッチ式フィルター実験装置

コンピューター制御プレート&フレーム圧濾器

コンピューター制御深層ろ過実験装置

深層ろ過実験装置

沈殿学習装置

コンピューター制御沈殿タンク

沈殿タンク

コンピューター制御排水・漏水タンク

排水・漏水タンク

品質

アフターサービス

クッキーの設定

クッキーの設定