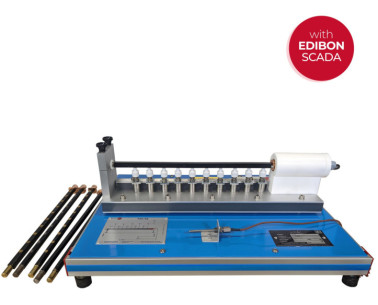

TCLFC コンピューター制御自由・強制対流熱伝導実験装置

革新的なシステム

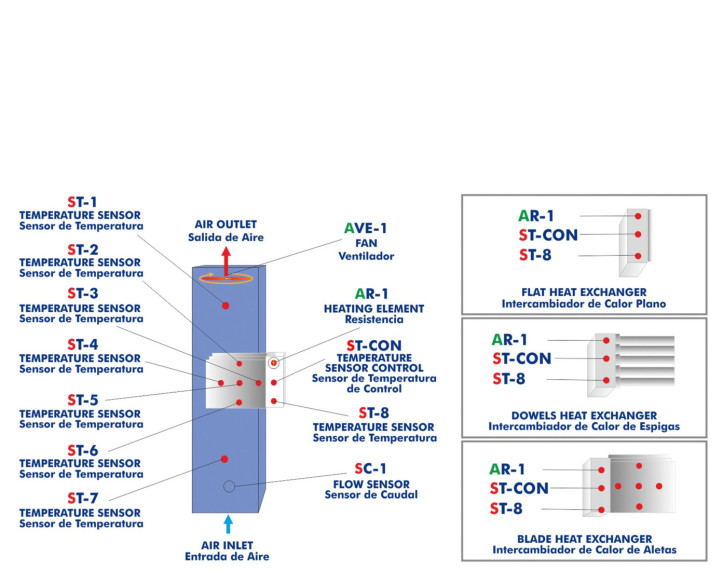

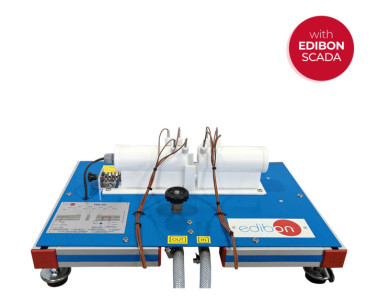

The Computer Controlled Free and Forced Convection Heat Transfer Unit, "TCLFC", designed by EDIBON, allows to study the efficiency of different exchangers, analyzing the heat transmission coefficients of each exchanger exposed to different airflows.

拡張

研究室

関連ニュース

概要

The Computer Controlled Free and Forced Convection Heat Transfer Unit, "TCLFC", designed by EDIBON, allows to study the efficiency of different exchangers, analyzing the heat transmission coefficients of each exchanger exposed to different airflows.

Fan placed in the upper part of the tunnel allows controlling the airflow that goes through the tunnel.

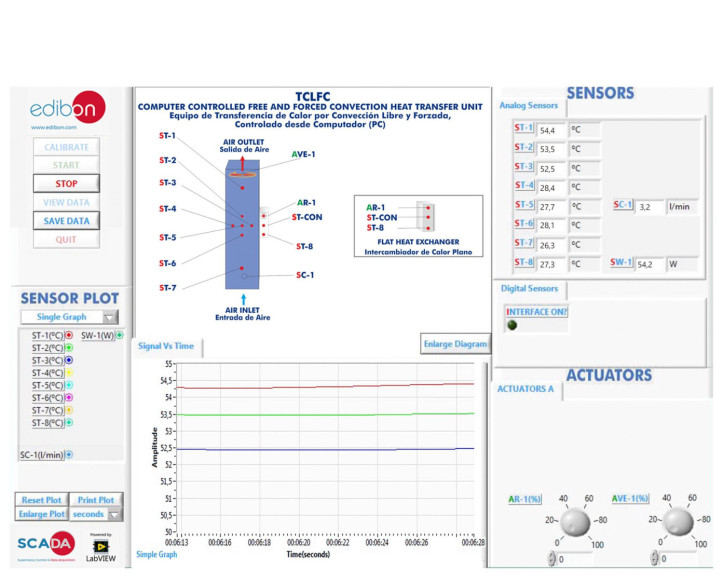

Control interface connectable to a computer contains the control circuits to measure temperatures, electrical control, electrical supply and speed control of the fan.

The interface provides an output to a computer where the values and graphics of all the variables involved in the practices are shown.

The airflow is measured with a flow sensor set at the inferior part of the tunnel.

This unit allows making a study of the heat transmission in three different types of exchangers:

- Flat exchanger.

- Pins exchanger.

- Fins exchanger.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Demonstration of the basic principles of free and forced convection.

- Comparison between free and forced convection.

- Free convection in flat surfaces.

- Forced convection in flat surfaces.

- Dependence of the heat transmission with the temperature.

- Dependence of the heat transmission with the speed of the fluid.

- Dependence of the heat transmission with the exchanger geometry.

- Temperature distribution in the additional surfaces.

- Study of the advantage of using pinned and finned surfaces in heat transmission in free convection.

- Study of the advantage of using pinned and finned surfaces in heat transmission in forced convection.

- Comparative study between the free convection of a horizontal surface and vertical surface.

- Determination of the Reynolds and Nusselt numbers.

より実用的な練習をして、ユニットを完成させる

- Sensors Calibration

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TCLFC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TCLFC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

利用可能な類似の機器

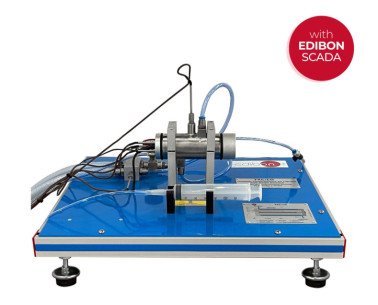

自由および強制対流による熱伝達装置(TSTCC用)

自由および強制対流による熱伝達装置(TSTCB用)

補完的な機器

熱伝達研究シリーズ、コンピュータ(PC)制御

線形熱伝導装置(TSTCC用)

放射状熱伝導装置(TSTCC用)

放射熱伝達装置(TSTCC用)

自由対流・強制対流および放射の複合熱伝達装置(TSTCC用)

拡張表面での熱伝達装置(TSTCC用)

温度測定における放射誤差装置(TSTCC用)

非定常熱伝達装置(TSTCC用)

液体および気体の熱伝導装置(TSTCC用)

自由および強制対流による熱伝達装置(TSTCC用)

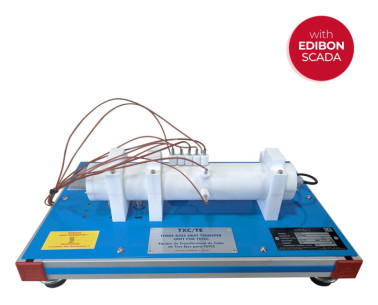

TSTCC用三軸熱伝達装置

品質

アフターサービス

クッキーの設定

クッキーの設定