CRCI Industrial Controllers Networking

INNOVATIVE SYSTEMS

The "CRCI" Unit enables to take the first steps in process automation using field buses, and provide the students the material for analyze a full operative industrial controllers network. It demonstrates the operation of a process control system based on a simple application.

Laboratories

RELATED NEWS

General Description

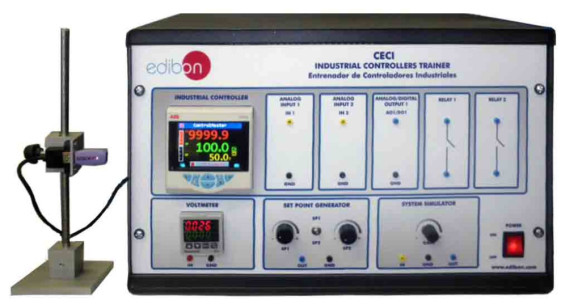

The Industrial Controllers Networking, "CRCI", unit is based on a modular design structure whose functionality is divided into different modules to allow the student a better understanding of the unit. The modules provided with the unit are: two Industrial Controllers, Set Point Generator, Interface Card (to be placed in a computer slot) and Control Configuration Software.

- 2 Industrial Controllers modules, each one is composed of: an industrial controller with 2 analog inputs and an analog/digital output. The analog inputs are used to connect the process variable value (PV) and set point value (SP) signals respectively. The analog/digital output is used for delivering the output process value (OP). The controller also has two relays. The industrial controller is connected via field bus (Profibus DP) through an interface card with a computer (PC).

- Set Point Generator module: it allows to generate a step signal by switching between two different selectable voltages. The voltage levels can be adjusted using two potentiometers.

- Interface Card (to be placed in a computer slot): it allows the controllers signals to be available for a computer PC, for further processing.

- Software, composed of:

- The OPC server configuration drivers: allows the modules data to be available for others programs.

- The Control Configuration Software: allows to set the industrial controllers parameters. Several functions such as recorders and alarm logs enable a simple control room function to be simulated.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Installation, connection and familiarization with the software.

- Familiarization with the navigation of an industrial controller (operator page screen, trend display screen, etc).

- Setting up an industrial controller to accommodate the analog inputs/outputs signals types and engineering and electrical units.

- Function of a digital industrial controller.

- Configuration of analog inputs/outputs signals of the industrial controller (electrical range, engineering units, fault detector, etc).

- Setting alarms and diagnostics generation.To learn and to familiarize with the operation and structure of a process control system under Profibus DP.

- Layout of a field bus system using the Profibus DP field bus.

- Study of OPC (OLE for Process Control) server function.

- Configuration of an industrial controllers networking through the software: Master and slave assignment.

- Reading control variables and PID parameters and displaying them on computer (PC) monitor.

- Scaling displays.

- Setting of an industrial controller using the front panel (configuration level, parameter level, operation control level, etc.).

- Remote setting of an industrial controller using the control configuration software (configuration level, parameter level, operation control level, etc.).

SIMILAR UNITS AVAILABLE

Field Bus Applications Unit

Computer Controlled Controller Tuning Unit

SUPPLEMENTARY EQUIPMENT

Industrial Controllers Unit

Computer Controlled Controller Tuning Unit

Field Bus Applications Unit

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences