EG6C コンピューター制御地熱エネルギー(高エンタルピー)実験装置

革新的なシステム

The Computer Controlled Geothermal (high enthalpy) Energy Unit, "EG6C", developed by EDIBON, has the aim of introducing the student in a renewable energy, increasingly important.

拡張

研究室

関連ニュース

概要

The Computer Controlled Geothermal (high enthalpy) Energy Unit, "EG6C", developed by EDIBON, has the aim of introducing the student in a renewable energy, increasingly important.

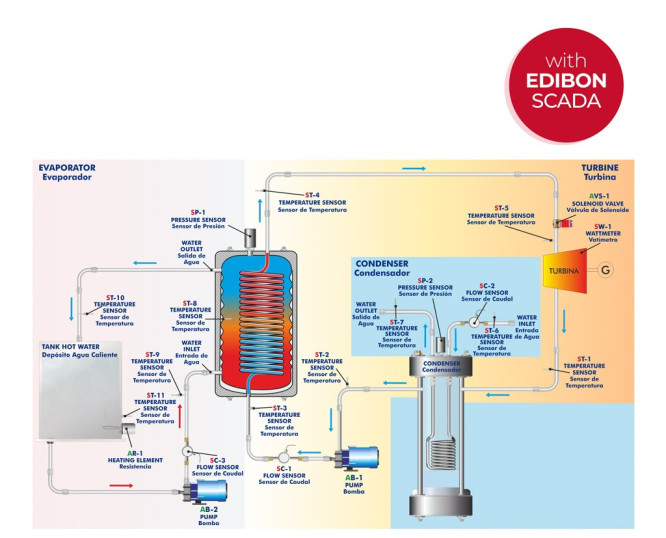

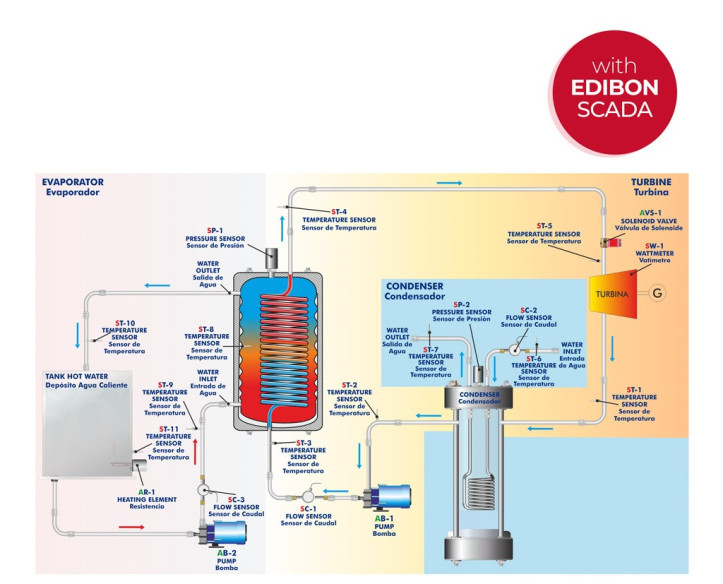

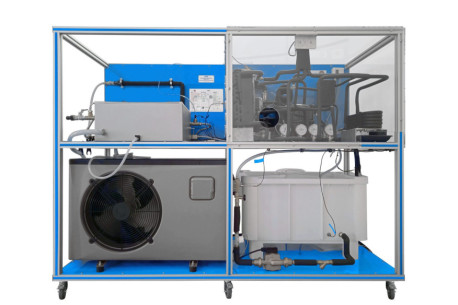

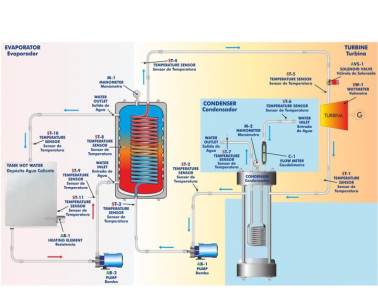

This unit simulates the steam produced in the well, by using a steam generator. Then the steam produced moves a turbine by means of a steam injector, which impacts against the blades of the turbine and generates work.

According to the energy which the steam (flow, temperature and pressure) has, there will be more or less work produced by the turbine.

This mechanical work is converted into electrical energy by an electric generator suppling a load.

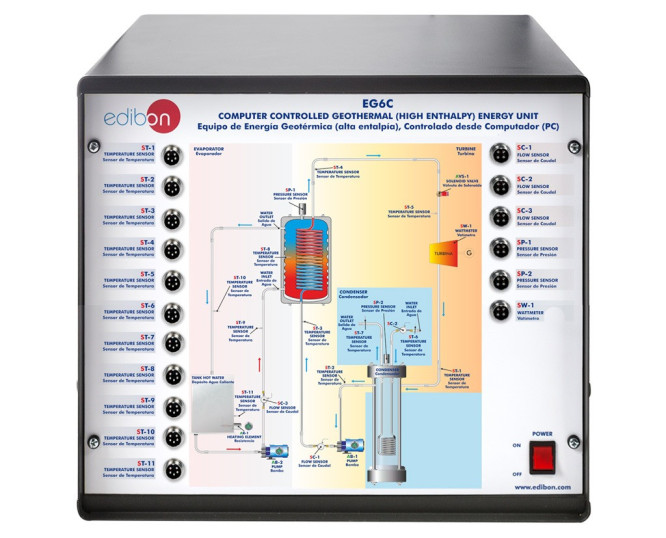

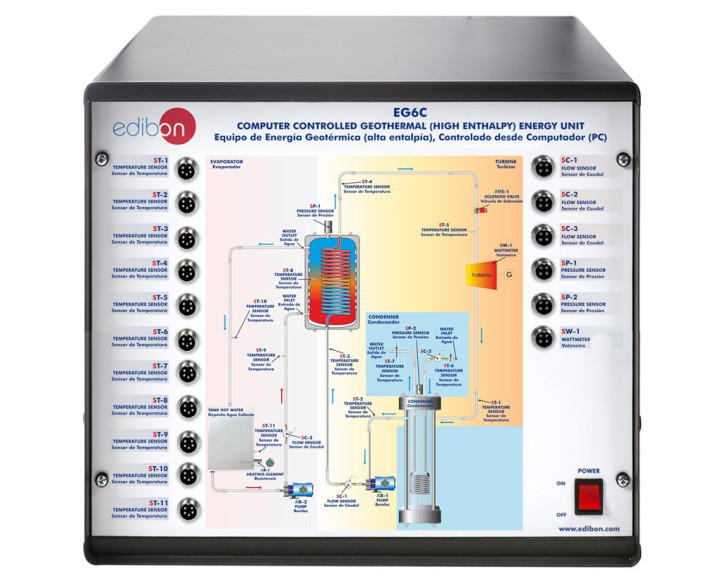

The unit is supplied with suitable instrumentation and sensors to monitor the most representative parameters measurements and to control from a computer.

The output energy supply an electric generator connected to a resistor. The power is measured by means a wattmeter.

The steam flow is an important variable and is measured by means of the condensed steam volume during a determined time.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- To familiarize the student with the Geothermal energy and all the stages of the process.

- Study the system with different steam temperatures.

- Study the system with different steam flows.

- Study the system with different steam pressures.

- Obtaining the characteristic curves of the steam turbine.

- Turbine efficiency.

- Thermal balances.

- To measure the electricity generated.

- Determination of thermal efficiency.

- Study of the specific steam consumption of the turbine.

- Determination of the total efficiency of the unit in function of the input energy and the consumption of the load.

- Sensors calibration.

より実用的な練習をして、ユニットを完成させる

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EG6C unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EG6C unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

利用可能な類似の機器

地熱エネルギー(低エンタルピー)実験装置

地熱エネルギー(高エンタルピー)実験装置

Computer Controlled Geothermal Energy Unit with Two-Well System

補完的な機器

地熱エネルギー(高エンタルピー)実験装置

コンピューター制御地熱エネルギー(低エンタルピー)実験装置

地熱エネルギー(低エンタルピー)実験装置

Computer Controlled Geothermal Energy Unit with Two-Well System

品質

アフターサービス

クッキーの設定

クッキーの設定