At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

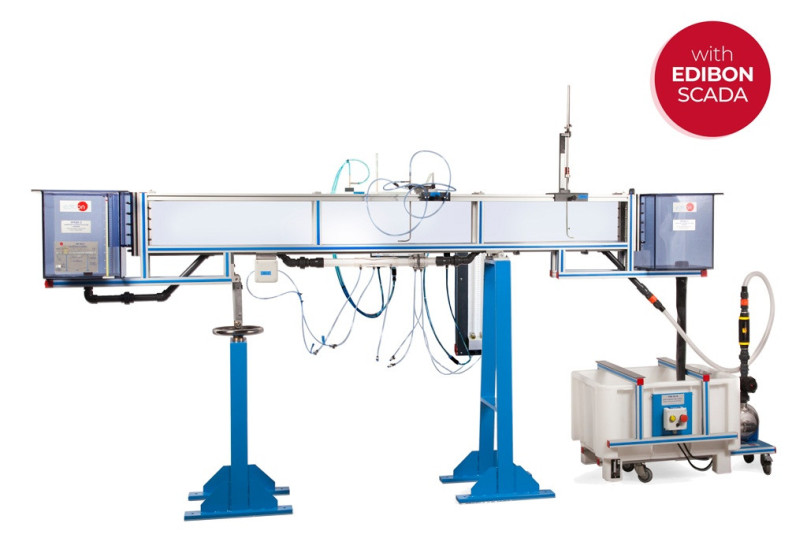

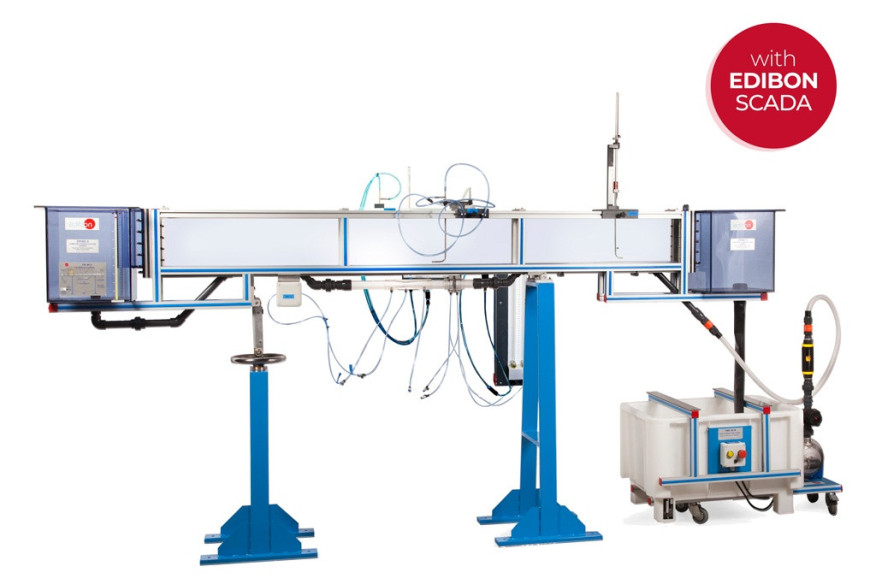

Recently, we have had the pleasure of making an installation at the University of Trinidad and Tobago

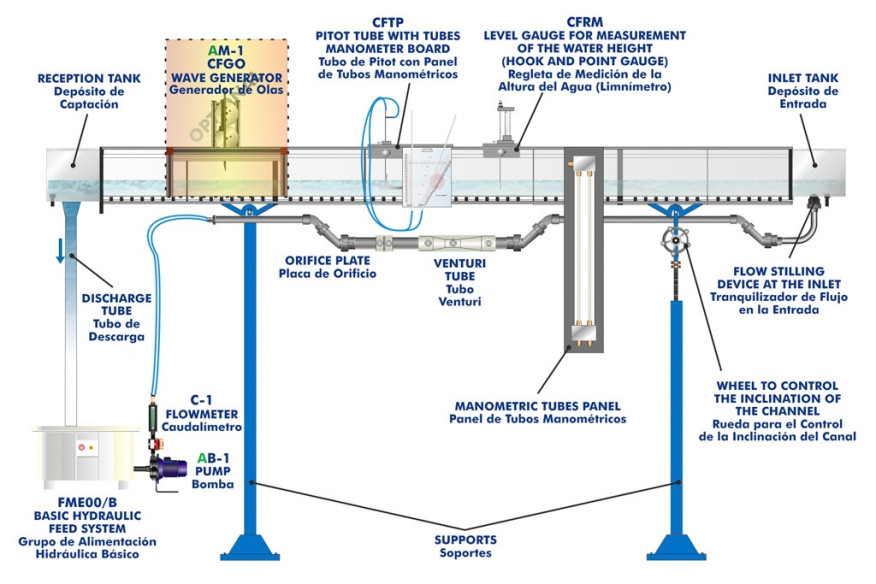

Our engineers carried out a successful installation at the University of Technology UTEC - Universidad de Ingeniería y Tecnología (Uruguay). Now, students and professors from the Department of Irrigation Systems Engineering, Drainage and Effluent Management will continue studying and researching...

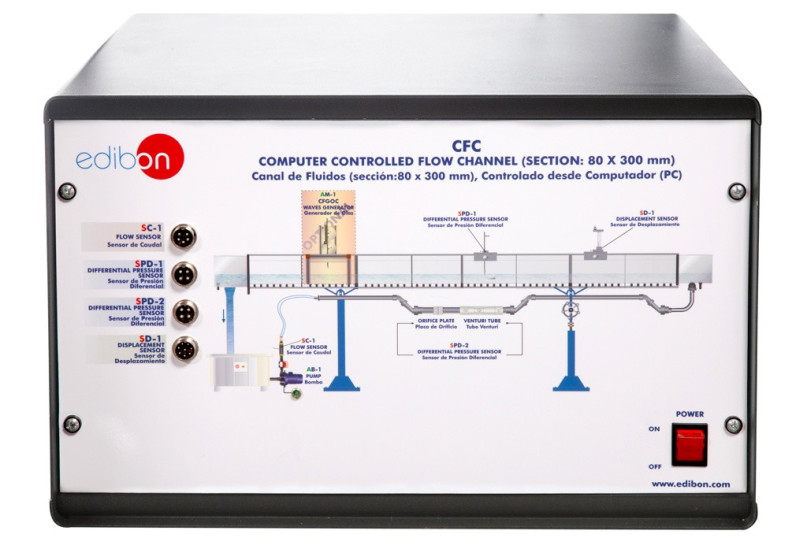

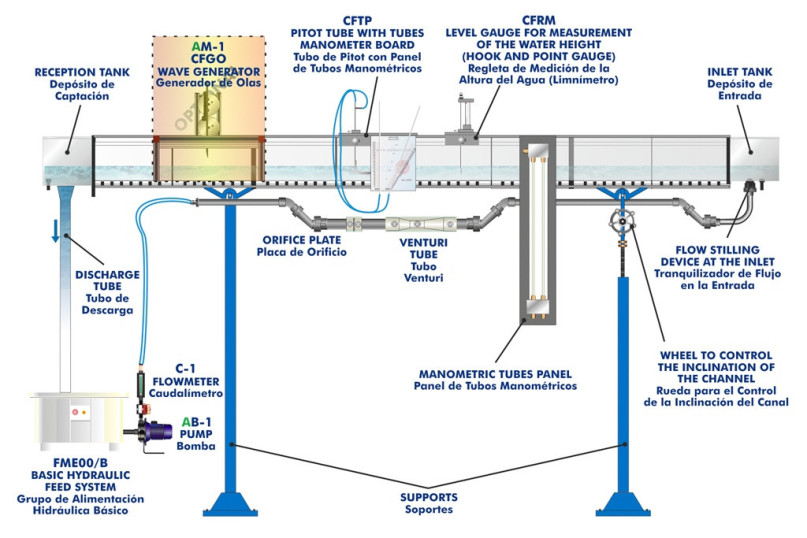

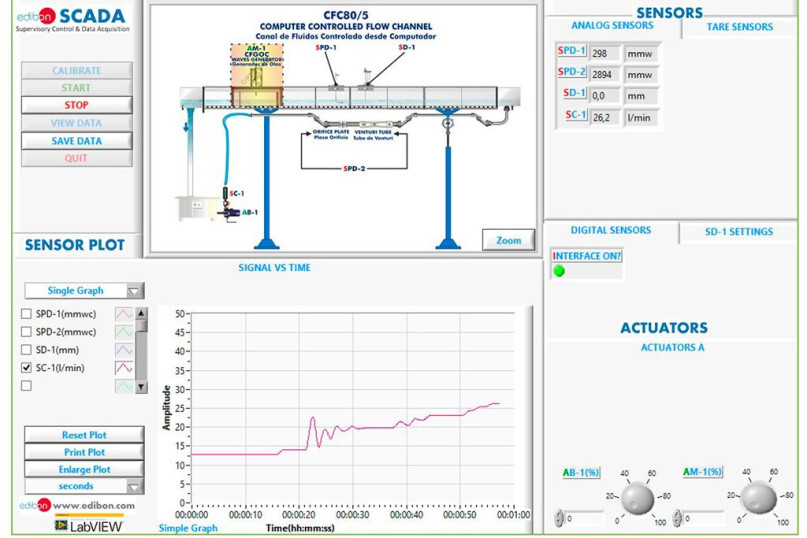

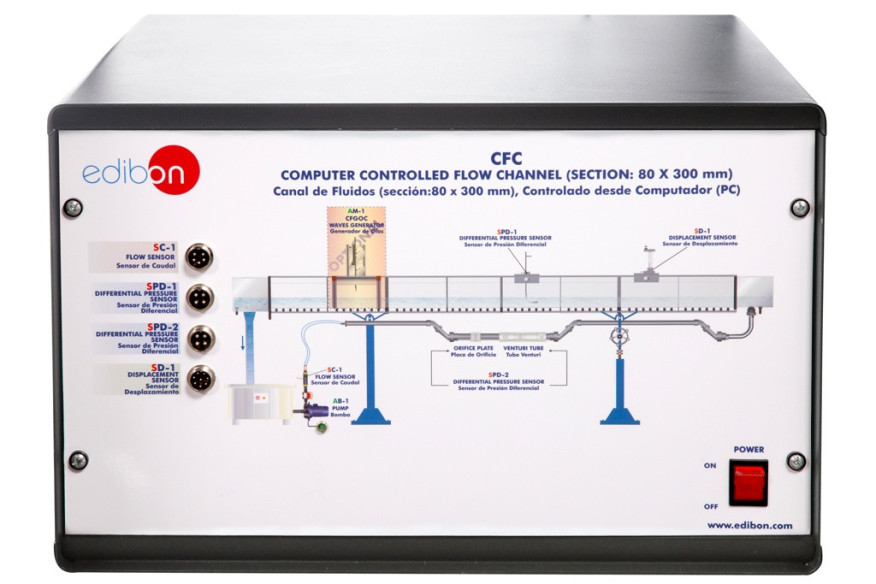

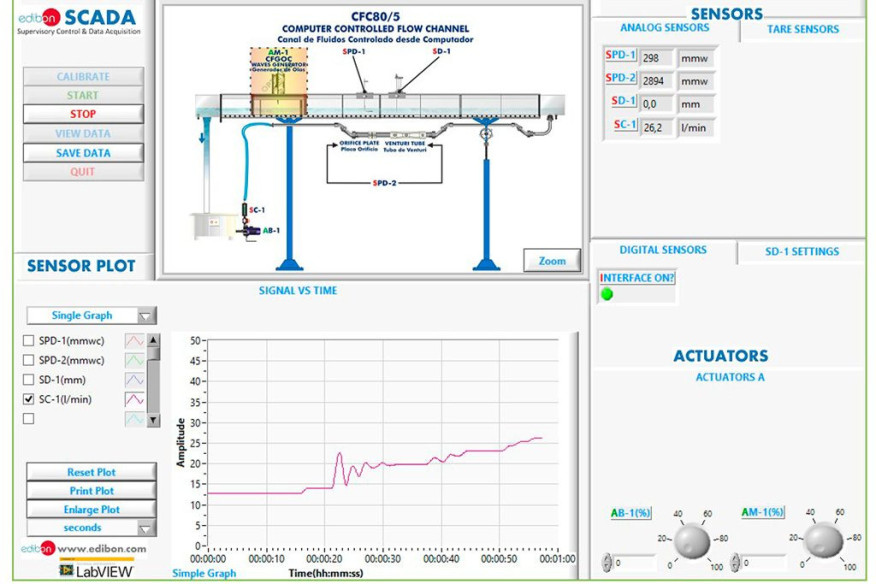

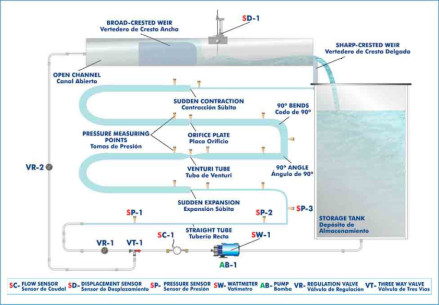

Are you a teacher or do you work as an engineering researcher? EDIBON offers courses for teachers and #research staff. Take a look at the course of Fluid Mechanics and learn about #fluids properties. #DiscoverEdibon #Engineering.

クッキーの設定

クッキーの設定