Pilot plants are small-scale processing plants designed to simulate industrial or research processes before large-scale implementation. They are essential for testing technologies, optimizing processes, and validating models before investing in mass production. These plants allow researchers and...

In a world where energy demand continues to rise and non-renewable resources are rapidly depleting, the need for sustainable, environmentally friendly solutions has never been more urgent. The circular economy and the use of organic biomass to produce biofuels are emerging as key answers to...

ダイレクトエアキャプチャー (DAC) は、液体溶媒や固体吸収剤との化学反応を利用して空気中のCO₂を直接除去する革新的な技術です。コストの高さやエネルギー消費といった課題はあるものの、DACは大気中のCO₂濃度を減らし、気候変動を緩和する潜在的な解決策を提供します。DACの研究開発を継続することが、その実現可能性と効果を向上させるために重要です。

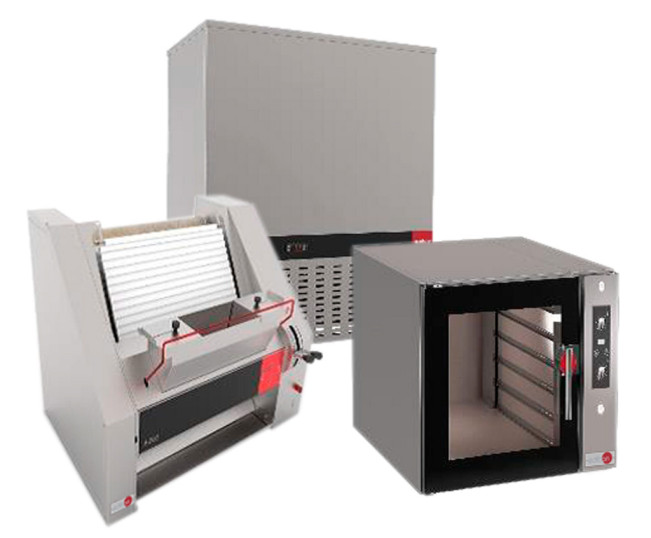

Discover how our innovative and sustainable pilot plants can transform food production. Ensure quality, efficiency, and sustainability at every stage of the production process.

クッキーの設定

クッキーの設定