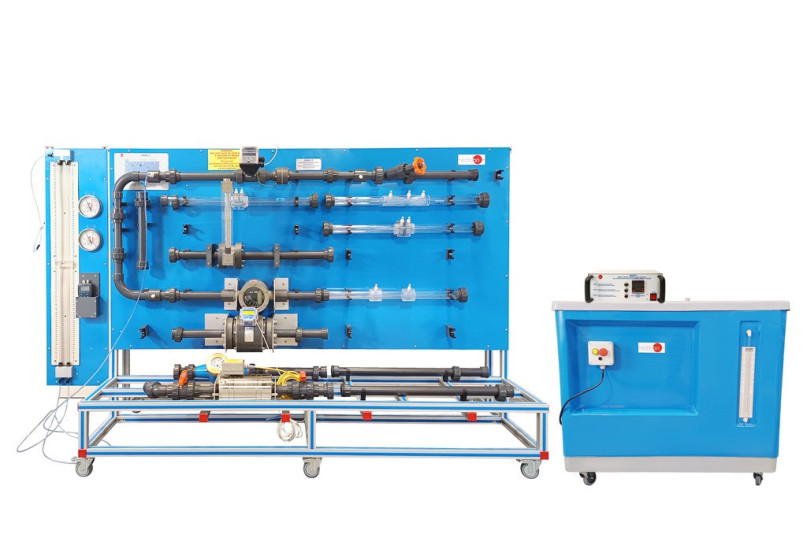

Flow Meters Demonstration, "FMDU", designed by EDIBON, demonstrates the important characteristics of fifteen types of flow meters used in the measurement of water flow through pipes or open channels.

The main element is the FMDU Base Unit, "FMDU-UB", is the flow meters support structure, that includes a service module (Hydraulics Bench) and flow meters.

A centrifugal pump draws water from the sump tank in the Hydraulics Bench and delivers it to a flow meter test pipe. Flow meters mounted in pipes can be fitted into the unit test zone quickly and easily. These meters give a variety of different measuring principles and degrees of accuracy.

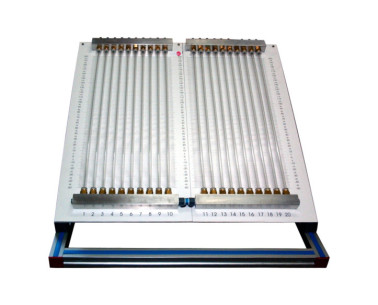

By using a water manometer or two Bourdon type manometers the pressure drop across each of the flow meter can be measured. Valves ensure rapid bleeding of all manometer pipework.

Water discharging from the flow meter on test is collected in the volumetric tank (in the Hydraulics Bench) where the flow may be determined absolutely. This tank is stepped to accommodate low or high flow rates and incorporates a stilling baffle to reduce turbulence. A level tube with a scale shows the water level. Water is returned to the sump tank by a dump valve.

A channel accommodates the FMDU Orifice Plate, "FMDU01", the FMDU Crump Weir, "FMDU12", and the FMDU Sharp-Crested Rectangular Weirs, "FMDU18", also the FMDU "H" Flume, "FMDU13" and FMDU Washington Flume, "FMDU14". By using the FMDU Hook and Point Gauge, "FMDU17" the levels in the channel can be determined.

クッキーの設定

クッキーの設定