TPCC 接触板冷冻机,计算机控制 (PC)

創新系統

The Computer Controlled Contact Plate Freezer, "TPCC", has been designed by EDIBON to introduce the student into the quick freezing processes, to study the advantages of these processes over other conventional freezing processes, as well as to study the thermodynamic process involved in those freezing technique.

扩展

化验室

相關新聞

一般說明

The Computer Controlled Contact Plate Freezer, "TPCC", designed by EDIBON, allow the student to freeze food products quickly by using an industrial freezing process.

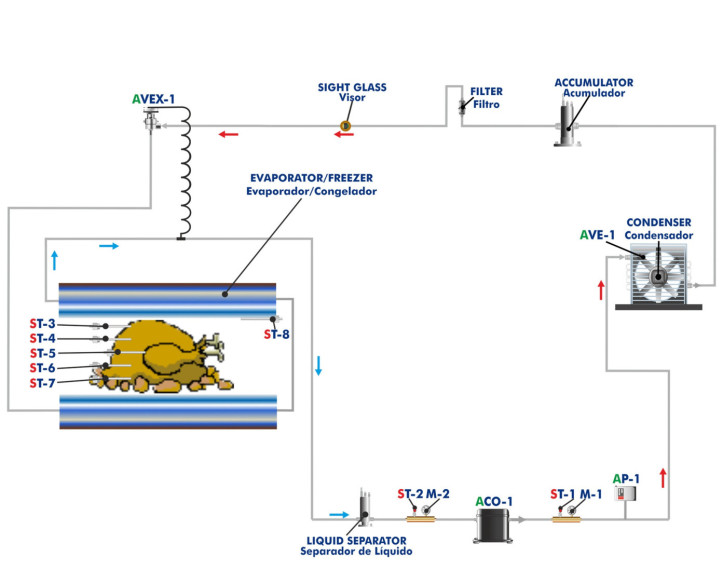

The unit includes a compression refrigeration circuit. It is based on mechanically forcing the circulation of a refrigerant through a closed circuit divided into two zones (high and low pressure), so that the fluid absorbs heat from the environment in a heat exchanger called evaporator (low pressure zone) and transfers heat in another heat exchanger called condenser (high pressure zone).

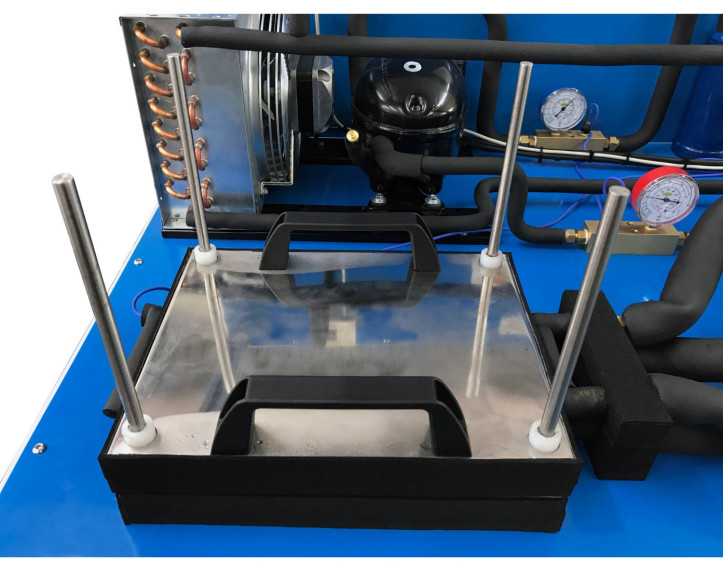

The main elements of the unit are: a hermetic compressor, a condenser with computer controlled fan, an expansion valve and a contact plate freezer-evaporator.

The contact plate freezer-evaporator consists of two freezing plates of 305 x178 mm. One is fixed and the other can be adjusted in height through two handles. The packaged food is placed on the fixed plate and can be frozen quickly.

Two temperature sensors and manometers are included to provide the conditions of the refrigerant at the inlet and outlet of the compressor. Besides, a temperature sensor located at the contact plate and five temperature sensors, which can be located in different points of the food product to be frozen, allow the student to monitor the product during the whole freezing process.

In addition, the circuit includes a sight glass to observe the state of the refrigerant, a filter, a storage tank to ensure a proper flow of refrigerant in the circuit and a liquid separator to prevent liquid from entering the compressor.

As a safety measure, the circuit includes a high pressure switch, which stops the cycle when the pressure is high.

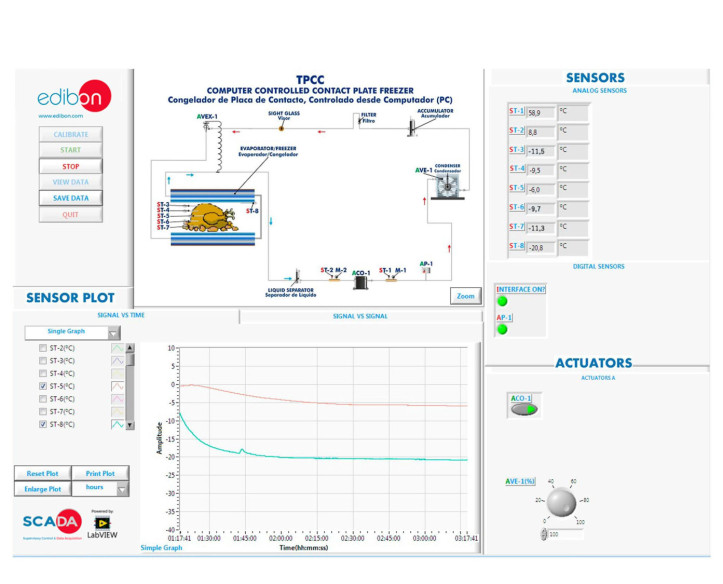

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

練習和指導練習

手册中包含的指导实践练习

- Study of industrial freezing processes in terms of preservation and effects on food.

- Investigate the effect of the freezing process on the morphological characteristics of food: size, shape, etc.

- Differences between freezing at home and industrial freezing (deep-freezing).

- Assess the effect of freezing rates on food preservation.

- Thermodynamic description of the process through temperature sensors.

- Evaluation of taste and texture.

- Study of the structural, composition and sensory effects of deepfreezing and thawing process.

- Study of the fundamentals of a deep-freezing system.

- Study of the operation, structure and elements of a deep-freezing system.

- Analysis of the freezing curves.

- Analysis of the theoretical freezing times.

- Sensors calibration.

与该单位进行更多实际操作

- Connections with physics (refrigeration) and biology (structure of foods).

- Study the effect of the temperature on bacteria.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TPCC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TPCC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

配套设备

喷雾干燥机,计算机控制 (PC)

喷雾干燥机

计算机控制的喷雾干燥和冷却设备

多功能处理容器,计算机控制 (PC)

计算机控制反渗透/超滤设备

板框过滤机,计算机控制 (PC)

Computer Controlled Hydrogenation Unit

Computer Controlled Deodorizing Unit

Advanced Computer Controlled Deodorizing Unit

连续循环油生产装置,计算机控制(PC)

Computer Controlled Liquid Packaging Teaching Unit

質量

售後服務

Cookies首选项

Cookies首选项