TFDC 教学用冷却罐,计算机控制(PC)

創新系統

The Computer Controlled Teaching Frigorific Tank, "TFDC", designed by EDIBON, allows to analyse the operation of a cold tank and to study the influence of temperature on the preservation of liquid foodstuffs.

化验室

相關新聞

一般說明

The Computer Controlled Teaching Cold Tank, "TFDC", designed by EDIBON, is a food grade stainless steel tank with a refrigeration cycle to maintain the liquid product at the desired temperature. It is effectively insulated with injected polyurethane.

The unit has a refrigeration cycle with refrigerant regulated by an expansion valve that guarantees maximum performance and minimum consumption. This unit includes all the necessary instruments and sensors to control and measure the most representative parameters.

The tank works in discontinuous mode, with the external outlet being the inlet and outlet of the working fluid. Once the product has been loaded, the valve closes and the control system is activated, allowing the cooling of the treated fluid. Once the required temperature has been reached and the operation is finished, the working fluid is withdrawn through the hose outlet.

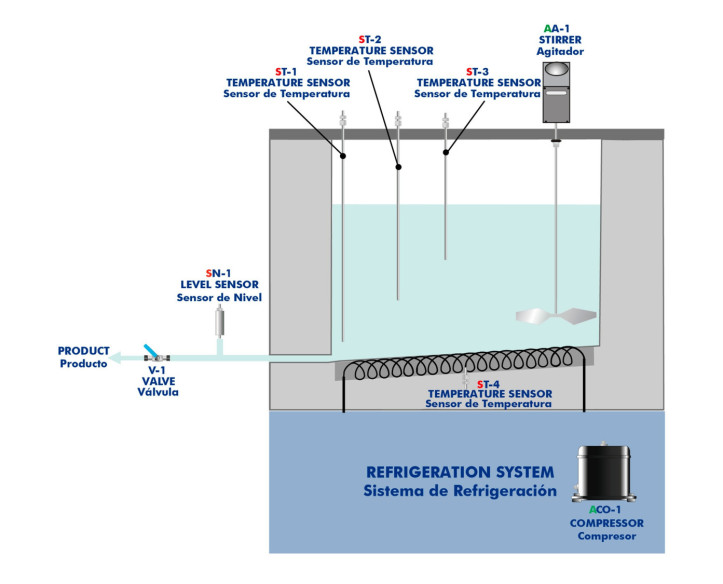

In this way, the Computer Controlled Didactic Cold Tank, "TFDC", is composed of:

- Tank and evaporator bottom: They are made of AISI 304 stainless steel, both the tank's inner tank and its outer coating. The lower bottom acts as an evaporator, converting the tank's refrigeration system into a "direct expansion" system. This evaporator has the appropriate surface area to achieve maximum heat exchange and thus prevent the formation of ice. All the joints of the internal tank in contact with the milk are welded and polished, with a resistance to corrosion and breakage equal to that of the base material used. The tank-refrigeration unit is mounted on a chassis made of AISI 430 stainless steel sections with adjustable feet. This chassis facilitates any handling of the tank, as well as its perfect levelling.

- Thermal insulation: Between the inner tank and the outer covering, there is a 50 mm thick layer of expanded polyurethane foam thermal insulation. This double wall allows compliance with the thermal insulation regulations for refrigerated tanks. This compliance consists of preventing the temperature of the milk at 4°C from exceeding 1°C in four hours, when the nominal volume remains at rest, without agitation, always at a maximum ambient temperature of 32°C.

- Lid and agitation: The open vertical tank is fitted with a lid on its upper part constructed of AISI 304 stainless steel with an AISI 304 stainless steel compensated hinge opening system. In its upper part and off-centre, there is a reduction motor with its corresponding stainless steel paddle which, rotating at 30 r.p.m., allows perfect homogenisation of the fat content of the milk in less than two minutes.

- Measuring the quantity of milk: The tank is equipped with a stainless steel scale in mm with an attachment point at the top of the tank. With the help of the mm/litre conversion table, attached in the ANNEXES section, it is possible to know the quantity of product in the cooling tank. In addition, it also allows automatic measurement with the level sensor provided for this purpose.

- Temperature measurement: It has a temperature sensor for the lower part of the unit and three others located at the bottom of the tank for the correct temperature control of the unit.

- Refrigeration unit: The tank is equipped with a hermetic compressor of optimum performance. The condenser, made of copper piping and aluminium fins, allows optimum performance at any ambient temperature. The cooling air is forced by a generously sized, low-noise fan.

- Electrical and control panel: It is located in the refrigeration unit and is equipped with all the necessary electrical protections.

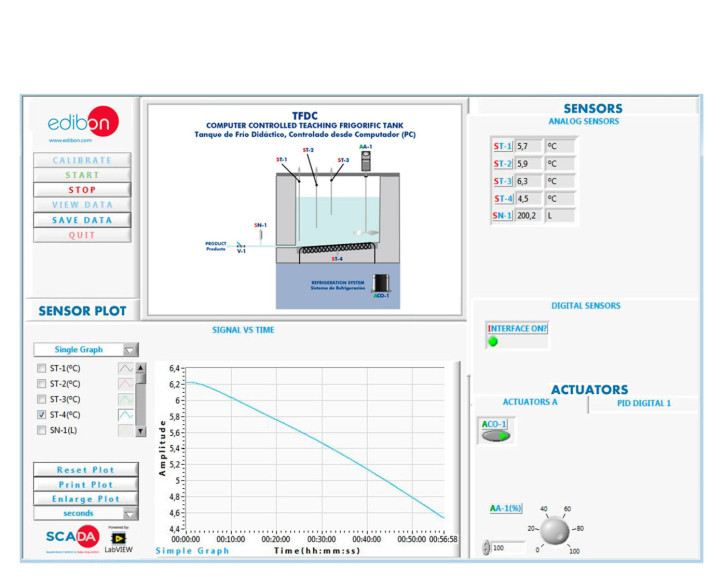

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

練習和指導練習

手册中包含的指导实践练习

- Influence of the temperature on the preservation of liquid foods.

- Influence of temperature on the properties of liquid foods.

- Influence of cold on milk microorganisms (requires laboratory material).

- Observation of a refrigeration system of a cooling tank.

- Energy balance

- Influence of milk properties on temperature exchange.

与该单位进行更多实际操作

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc. in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TFDC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TFDC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

配套设备

喷雾干燥机,计算机控制 (PC)

喷雾干燥机

计算机控制的喷雾干燥和冷却设备

多功能处理容器,计算机控制 (PC)

计算机控制反渗透/超滤设备

板框过滤机,计算机控制 (PC)

Computer Controlled Hydrogenation Unit

Computer Controlled Deodorizing Unit

Advanced Computer Controlled Deodorizing Unit

连续循环油生产装置,计算机控制(PC)

Computer Controlled Liquid Packaging Teaching Unit

質量

售後服務

Cookies首选项

Cookies首选项