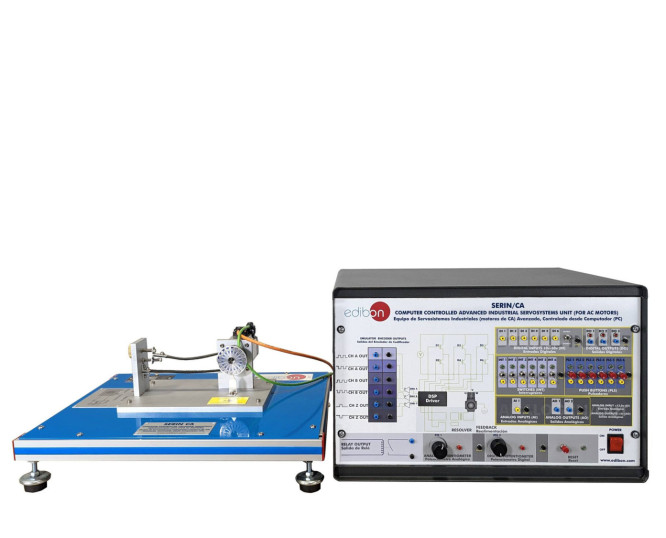

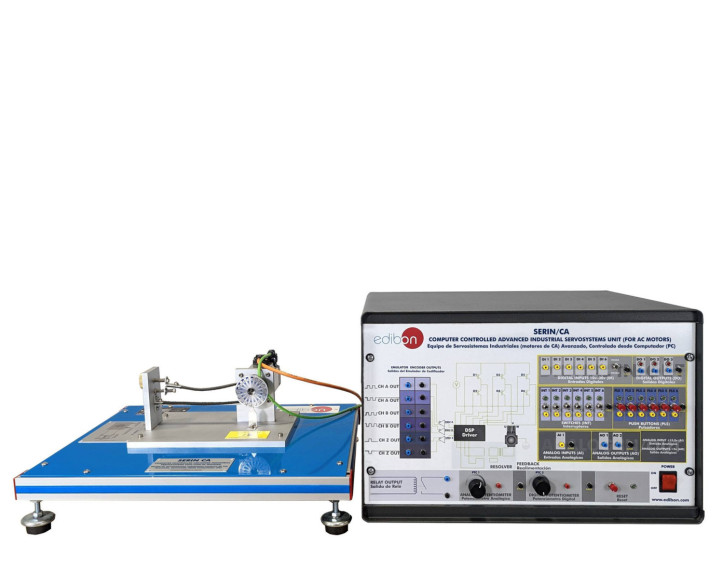

The Computer Controlled Advanced Industrial Servosystems Unit (for AC Motors), "SERIN/CA", has been designed by EDIBON for the detailed study of the three main control methods used in servomechanisms: position control, speed control, and torque control.

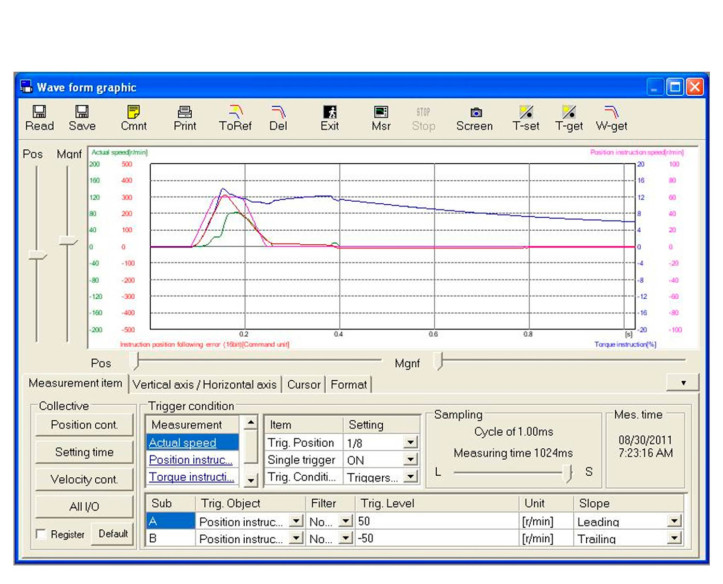

Position control enables the precise movement of loads between defined points, speed control regulates rotational speed or displacement over time, and torque control maintains a constant rotational force, which is essential in applications with variable loads.

Hands-on access to these three control modes allows students to acquire practical knowledge of how they are implemented in real automation systems.

With the "SERIN/CA", students can observe how these principles are applied in real time by experimenting with different control modes and system configurations.

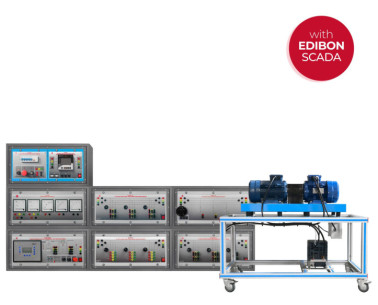

To support practical learning, the "SERIN/CA" includes the following modules that emulate and control key elements of a real servo system:

- Encoder emulator: provides feedback signals for position control using A, B, and Z channels.

- Analog and digital potentiometers: allow practice with both speed control (PTC1) and position control (PTC2).

- Digital inputs and outputs: 6 inputs and 3 outputs to modify system functions and monitor its status.

- Analog inputs and outputs: used for speed and torque control, as well as signal feedback.

- Digital switches and push buttons: enable activation of inputs or interaction with external systems such as PLCs.

- Relay output: can be used to trigger alarms or control external devices.

- Reset button: resets the system and loads new parameters from the software.

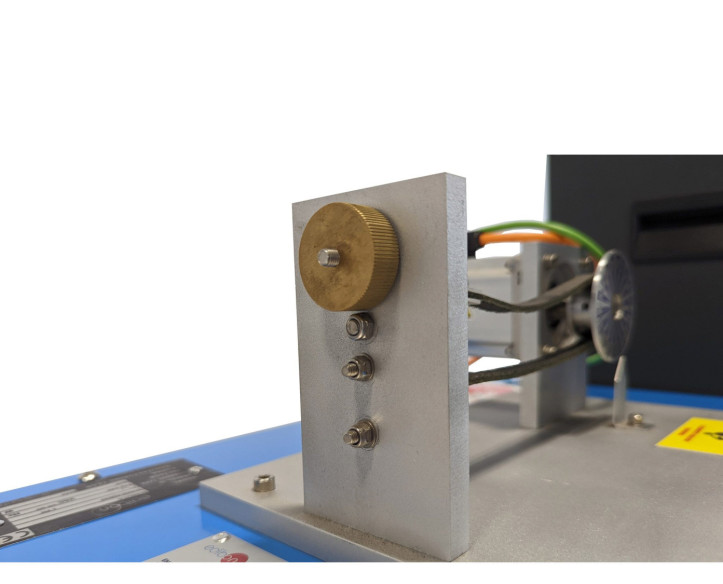

- AC motor with brake: the adjustable brake simulates different load conditions, making the experiments more realistic.

Its architecture and computer-controlled environment allow a wide range of experiments, from basic exercises to advanced closed-loop control and system integration.

This unit is ideal for vocational training centers, universities, and technical institutions seeking a robust, versatile, and fully practical training solution.

Cookies首选项

Cookies首选项