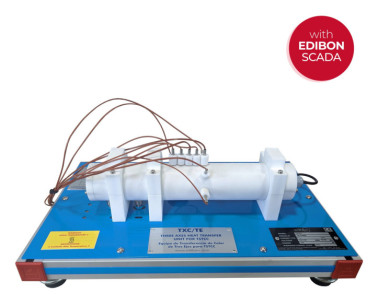

TXC/ER Gerät für Strahlungsfehler bei Temperaturmessungen für TSTCC

INNOVATIVE SYSTEME

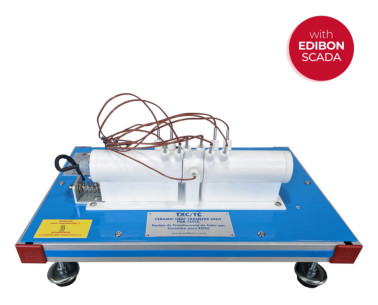

The Radiation Errors in Temperature Measurement Unit for TSTCC, "TXC/ER," allows the study of how temperature measurements can be influenced by sources of thermal radiation.

Erweiterungen

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Radiation Errors in Temperature Measurement Unit for TSTCC, "TXC/ER," allows the study of how temperature measurements can be influenced by sources of thermal radiation.

Bench-top unit to demonstrate how temperature measurements can be influenced by sources of thermal radiation.

The objective of this unit is to measure the error in a black thermocouple due the radiation with respect with another normal thermocouple where there are not radiative shielding in comparison when there are radiative shielding, error in function of material of the thermocouple’s capsule, size of the thermocouple, etc.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Measurement the errors in thermocouples in function of its painting, material of its capsules, size.

- Radiation errors in temperature measurement and minimization of radiation errors due to shielding.

- Influence of the air flow on radiation errors in temperature measurement.

- Calibration of sensors.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Heat transfer from geometry.

- Effect of cross-sectional shape on heat transfer from a geometry.

- Heat transfer from geometries of two different materials.

- Radiation errors in temperature measurements.

- Effect of air velocity on measurement errors.

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ÄHNLICHE VERFÜGBARE GERÄTE

Gerät für lineare Wärmeleitung für TSTCC

Gerät für radiale Wärmeleitung für TSTCC

Gerät für Wärmeübertragung durch Strahlung für TSTCC

Gerät für Wärmeübertragung an einer erweiterten Oberfläche für TSTCC

Gerät für instationäre Wärmeübertragung für TSTCC

Gerät für die thermische Leitfähigkeit von Flüssigkeiten und Gasen für TSTCC

Gerät zur Wärmeübertragung durch freie und erzwungene Konvektion für TSTCC

Gerät für dreiachsigen Wärmetransfer für TSTCC

Gerät für Wärmeübertragung (Metall zu Metall) für TSTCC

Gerät für Wärmeübertragung durch Keramik für TSTCC

Gerät für Wärmeübertragung durch Isoliermaterial für TSTCC

ERGÄNZENDE AUSRÜSTUNG

Serie zur Untersuchung des Wärmeübergangs, computergesteuert (PC)

Steuer-Interface-Box für TSTCC (gemeinsam für alle Module des Typs "TXC")

Gerät für lineare Wärmeleitung für TSTCC

Gerät für radiale Wärmeleitung für TSTCC

Gerät für Wärmeübertragung durch Strahlung für TSTCC

Kombiniertes Gerät für freie und erzwungene Konvektion und Strahlung für TSTCC

Gerät für Wärmeübertragung an einer erweiterten Oberfläche für TSTCC

Gerät für instationäre Wärmeübertragung für TSTCC

Gerät für die thermische Leitfähigkeit von Flüssigkeiten und Gasen für TSTCC

Gerät zur Wärmeübertragung durch freie und erzwungene Konvektion für TSTCC

Gerät für dreiachsigen Wärmetransfer für TSTCC

Gerät für Wärmeübertragung (Metall zu Metall) für TSTCC

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen