PSMC Computer Controlled Magnetic Separation Unit

創新系統

The Computer Controlled Magnetic Separation Unit, "PSMC", has been designed to understand the operation of a magnetic rotary drum used to classify materials of different magnetic characteristics.

扩展

化验室

相關新聞

一般說明

The Computer Controlled Magnetic Separation Unit, "PSMC", has been designed to understand the operation of a magnetic rotary drum used to classify materials of different magnetic characteristics.

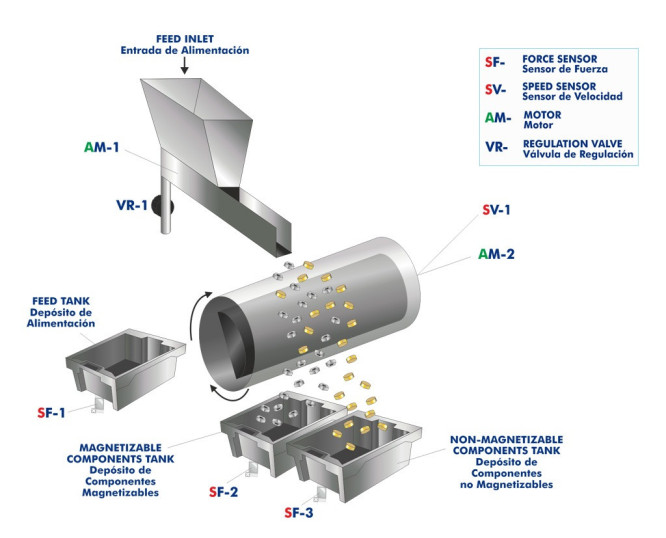

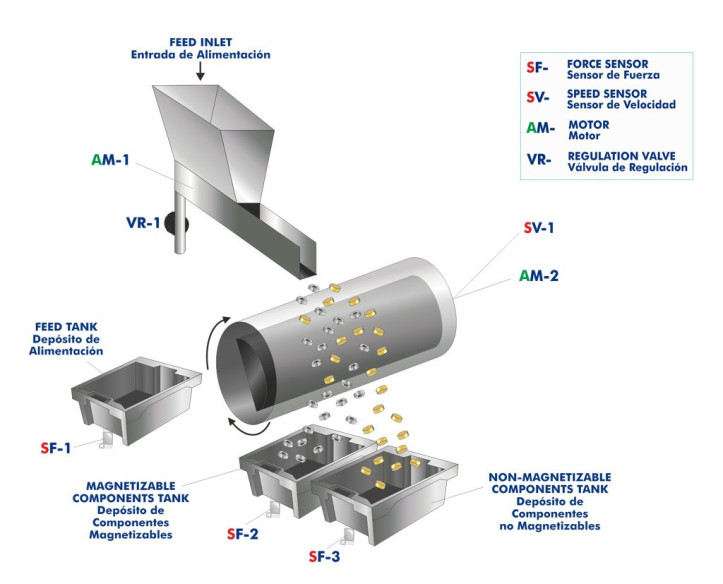

The main components of the unit are: a feed hopper with a vibrating trough, a non-magnetic rotary drum and a permanent magnet acting in an area of 180º of the rotary drum.

The process starts when the feed material (a mixture of components with different magnetic properties) is introduced in the hopper and the vibrating trough moves it to the inlet of the rotary drum. The trough is controlled by computer. The inlet flow to the drum is controlled by varying the frequency of the vibrating trough, the amplitude of the vibration and its distance from the hopper. When reaching the computer controlled drum, the non-magnetizable components are not affected by the permanent magnet and drop to the first tank. However, the magnetizable components adhere to the magnet and drop later on in the other tank, when they are out of the magnet magnetic field reach.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

練習和指導練習

手册中包含的指导实践练习

- Study of the separation techniques of solid mixtures with different magnetic properties in a magnetic separation drum.

- Calculation of the mass balance of the feed material.

- Efficiency of the separation process in function of the feed flow rate.

- Efficiency of the separation process in function of the mixing ratio of the feed material.

- Efficiency of the separation process in function of the type of feed material.

- Variation of the separation efficiency in function of the drum rotation speed.

与该单位进行更多实际操作

- Sensors calibration.

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PSMC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PSMC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

配套设备

半连续离心分离器,容量1000升,由计算机和触摸屏控制 (PC)

Computer Controlled Continuous and Batch Filtration Unit

Continuous and Batch Filtration Unit

板框过滤机,计算机控制 (PC)

计算机控制深床过滤装备

深床过滤装置

泥沙研究设备

计算机控制沉淀池

沉淀池

计算机控制排水和防渗水槽

排水和防渗水槽

質量

售後服務

Cookies首选项

Cookies首选项