At EDIBON, we are proud to contribute to the educational development at the Uganda Petroleum Institute Kigumba (UPIK) through the installation of some of our applications.

At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

Electricity is a form of energy resulting from the movement of electrons through a conductor. This physical phenomenon is essential for the operation of a wide variety of devices and systems we use daily, from household appliances to complex industrial systems.

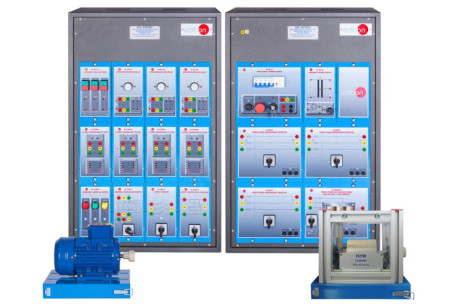

We are very pleased that we have recently completed the installation of two of our equipment, the AEL-ACEMT and the AEL-DCEMT at the Papua New Guinea University of Technology. Dept. Electrical and Communications Engineering. With this equipment designed by EDIBON it will be easier for them to...

Today we are at the beginning of a new era, named ‘Industrie 4.0’. Let´s explain a little further the concept "Industrie 4.0"!

Cookies首选项

Cookies首选项